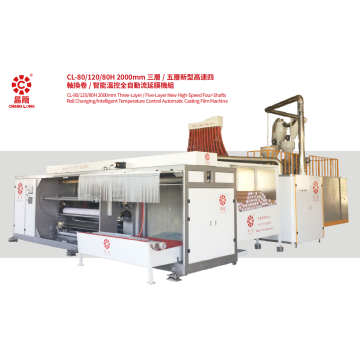

1500mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

Elevate your packaging operations with our 1500mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine, expertly engineered for businesses requiring exceptional film quality and efficient production capabilities. This machine is adept at creating both functional and protective films, making it a versatile asset in various industries.

Key Features and Benefits

Versatile Production: Capable of producing both three-layer and five-layer films, this machine caters to a broad range of packaging needs. From simpler applications using the 1500MM Plastic Stretch Film Machine Unit for regular wrapping to more complex needs requiring the 1500MM Black Stretch Film Machine Unit for high-strength applications.

Intelligent Automation: Streamline your operations with an automation system that orchestrates everything from feeding raw materials to the output of the finished product, significantly reducing labor costs and human error.

High-Speed Production: Meet demanding production schedules with our machine’s high output capabilities, essential for maintaining a steady supply chain and workflow, characteristic of the 1500MM Packaging Stretch Film Machine Unit.

Superior Film Quality: Utilizing advanced co-extrusion technology, the machine offers meticulous control over film specifications, ensuring each roll meets stringent quality standards with exceptional clarity and strength. This is particularly crucial for products like the 1500MM Hand Stretch Film Machine Unit, where manual handling and durability are key.

Customization Options: We understand that each business has unique needs. Discuss potential customizations with our team to tailor the machine to your specific requirements.

How It Works

The co-extrusion process flawlessly combines multiple layers of plastic resin to produce a single high-performance film. These layers can be varied to incorporate properties like increased strength or enhanced barrier protection, providing a custom solution for different applications.

Ideal Applications

Logistics and Shipping: Ensures exceptional protection for pallets and boxes during transportation.

Food Packaging: Ideal for wrapping perishable items, helping to maintain freshness and prevent contamination.

Industrial Packaging: Perfect for securing heavy-duty items, ensuring they're well-protected during storage and transit.

Upgrade Your Packaging Process

Investing in our 1500mm casting film machine means not only elevating your packaging process but also enhancing product safety and presentation. With its advanced features and efficient performance, you can reduce operational costs, boost productivity, and consistently produce high-quality films. Reach out today to learn more about how our specialized film machine can benefit your business and resolve your packaging challenges efficiently.

1. The vacuuming device is used to make the produced film better fit to the casting cooling crucible, and the cooling effect is better, and the film performance is improved.

2. The casting cooling part adopts a large-diameter double-layer loop cooling system to make the surace temperature of the cooling crucible uniform and improve the cooling effect.

3. A fenced staircase is instaled around the unit, which is user-friendly and convenient or operators to check the condition of the machine at anvtime.

4. Fully automatic edge material recovery device (patented technology) to achieve crushing and recycling of the edge material line.

5. Automatic paper-feeding tube and automatic unwinding device (patented technology),. no manual manual needed, fully automatic production, reducing labor intensity and greatly improving production efficiency.

6. The metering pump sensing technology precisely controls the extrusion presure of the unit to achieve linear extrusion and improve film performance.

7. You can choose to wear 1.5m paper tube at onetime and 1.5m pipe unloading style, The appearance size ofthis style is 13*6.5*4.5 meters, which greatly saves operation time and improves production efficiency.