1500mm High-Speed Casting Stretch LLDPE Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

- Port:

- Shenzhen Port, Yangjiang Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China Mainland |

|---|---|

| Productivity: | 6.5-7 Tons/24 hours |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

| Port: | Shenzhen Port,Yangjiang Port |

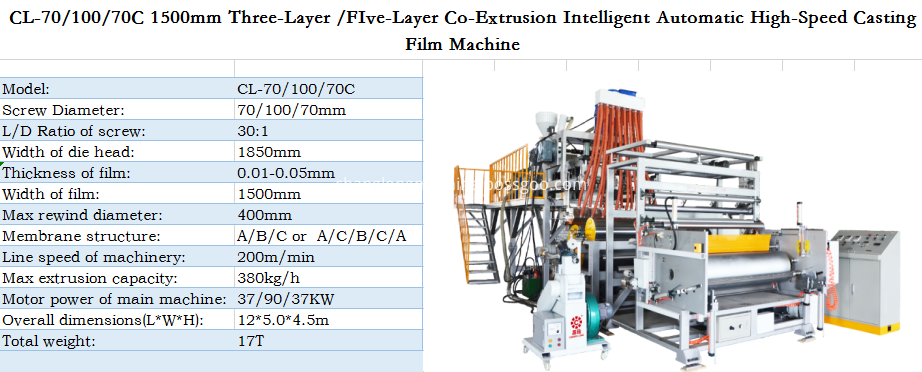

CL-70/100/70C 1500mm Three-Layer / Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Stretch Wrapping Film Machine

Model Configurations:

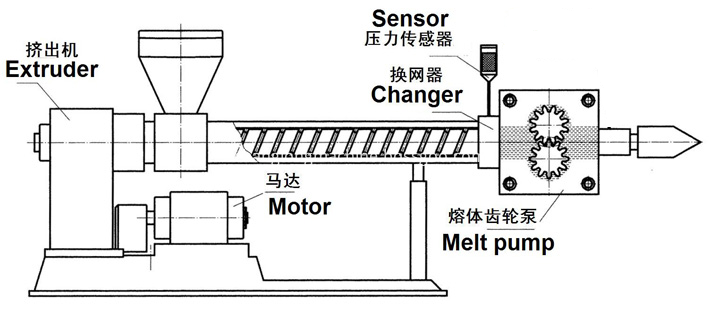

Plastic Melt Metering Pump

- Plastic melt metering pump is more and more important in extrusion process, especially in high-end products industries, such as high quality sheets, pipes, BOPP, optical cable.

- Installing the melt metering pump in the cast stretch film unit, which can keep the production constantly and efficiency. The pump can improve the product quality, stable the production and decrease the energy consume.

- The housing is made of chromium-nickel alloy or nickel-base alloy, titanium alloy. The gear is made of quenching chromium steel, other metal materials are also applicable. Bearing is made of graphite NIAG, zirconium oxide or quench tool steel.

Advantages Of Plastic Melt Metering Pump:

1、FAST AND STABLE FLOW SUPPLY

Eliminated the extruder’s pulsation wave. Improve the product quality, decrease the defective rate, and decrease the waste, which can save 2% material and 25% of the unit power consumption.

2、STABLE AND EFFICIENCY PRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

3、INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after install the melt pump, the max pressure wave value is the pressure after pump. Which can make the inner pressure of the extruder decrease, the melt shear strength decrease, the temperature curve gently, and restrain the temperature rising. Also the melt pump can avoid the damage to the extruder from the high pressure.

Product Features:

- The vacuuming device is used to make the produced film better fit to casting cooling crucible,and the cooling effect is better,and the film performance is improved.

- The casting cooling part adopts a large-diameter double -layer loop cooling system to make the surface temperature of the cooling crucible uniform and improve the cooling effect.

- A fenced staircase is installed around the unit,which is user-friendly and convenient for operator to check the condition of the machine at any time.

- Fully automatic edge material recovery device(patented technology)to achieve crushing and recycling of the edge material line.

- Automatic paper-feeding tube and automatic unwinding device(patented technology),no manual,fully automatic production,reducing labor intensity and greatly improving production efficiency.

- You can choose to wear 1.5m paper tube at one time and 1.5m pipe Unloading style.The appearance size of this style is 13*6.5*4.5 meters,which greatly saves operation time and improves production efficiency.

Finished Product:

Delivery Packing:

Related Keywords