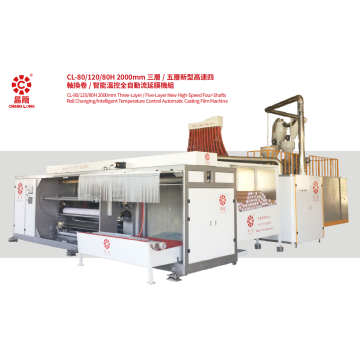

1500mm Casting LLDPE Stretch Wrapping Film Unit

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

- Port:

- Shenzhen Port, Yangjiang Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China Mainland |

|---|---|

| Productivity: | 3-3.5T / 24 hours |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

| Port: | Shenzhen Port,Yangjiang Port |

ChangLong Technological innovation, embark on an international journey of intelligence.

Changlong won the national high-tech enterprise in 2013 and was also the first national high-tech enterprise in the industry.The company has mastered the core technologies and has 2 invention patents, 28 utility model patents and 9 software copyrights.

In the cast film industry, Changlong strives to be a leader in the technological innovation of equipment, "inheriting craftsmanship and manufacturing craftsmanship." In 2000, Changlong successfully manufactured the first cast film device with a melt metering pump in China; in 2017, it cooperated with Gefran to develop an integrated intelligent temperature control system. Changlong became the world's top three in the machinery industry. The first company in China is also the exclusive manufacturer of this technology in cast film equipment. Changlong officially embarked on an international journey of intelligent equipment.

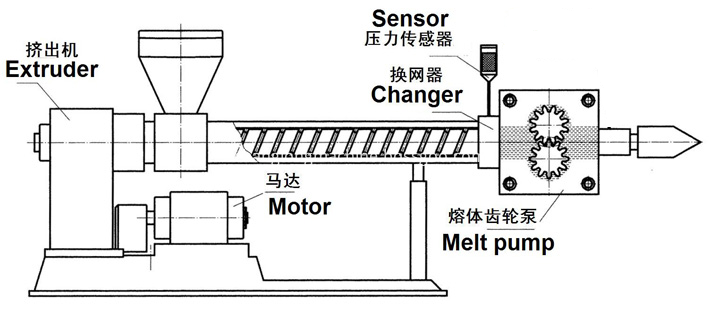

Plastic melt metering pump - Make the film be more uniformity and good tensile-strength.

Plastic Melt Metering Pump

- Plastic melt metering pump is more and more important in extrusion process, especially in high-end products industries, such as high quality sheets, pipes, BOPP, optical cable.

- Installing the melt metering pump in the cast stretch film unit, which can keep the production constantly and efficiency. The pump can improve the product quality, stable the production and decrease the energy consume.

- The housing is made of chromium-nickel alloy or nickel-base alloy, titanium alloy. The gear is made of quenching chromium steel, other metal materials are also applicable. Bearing is made of graphite NIAG, zirconium oxide or quench tool steel.

Advantages:

1、FAST AND STABLE FLOW SUPPLY

Eliminated the extruder’s pulsation wave. Improve the product quality, decrease the defective rate, and decrease the waste, which can save 2% material and 25% of the unit power consumption.

2、STABLE AND EFFICIENCY PRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

3、INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after install the melt pump, the max pressure wave value is the pressure after pump. Which can make the inner pressure of the extruder decrease, the melt shear strength decrease, the temperature curve gently, and restrain the temperature rising. Also the melt pump can avoid the damage to the extruder from the high pressure.

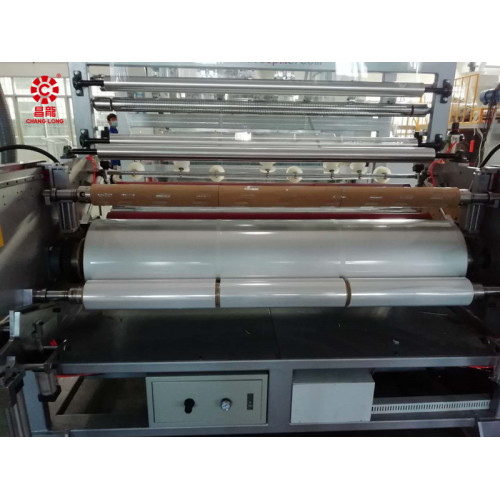

Specification of Model CL - 65 / 90 A:

8 * 3.5 * 3.9 m

Model:

CL - 65 / 90 A

Screw Diameter:

65 / 90 mm

L / D Rotio Of Screw:

30 : 1

Width Of Die Head:

1850 mm

Width Of Film:

1500 mm

Thickness Of Film:

0.01 - 0.05 mm

Max Rewind Diameter:

400 mm

Membrane Structure:

A / B Or A / B / A

Line Speed Of Machinery:

135 m / min

Max Extrusion Capacity:

200 Kg / h

Motor Power Of Main Machine:

22 / 45 KW

Overall Dimensions (L * W * H ):

Total Weight:

10.2 T

Finished Product:

Delivery Packing:

Related Keywords