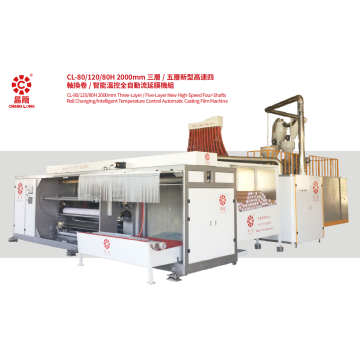

Atomatic Co-Extrusion Casting Film Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

- Port:

- SHEKOU, Yantian Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 200kg/ h |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

| Port: | SHEKOU,Yantian Port |

Atomatic Co-Extrusion Casting Film Machine:

The stretch film, also called as elastic film, is a kind of soft polyethylene plastic film with good transparency, elasticity and intensity. In case of non-heating it, it can stretch in length and breadth. It can wrap the products of food packaging and pallet packaging , etc with its own autohension and make them keep tension and unloosen for a long time.

Product Description :

1.Thickness adjustment scope:10µm-50µm 2.Screw Diameter : 65/90mm

3.Width of effective film:1 500mm(max) or 3*500mm ; 4.Structure of film layers: A/B or A/B/A Co-extruded;

5.The fit material:LLDPE; 6.Extrusion capacity(max):200kg/h.

7.Line Speed: 150m/min 8.Overall Dimensions(L*W*H) : 8*3.5*3.9m

9.Total Weight : 10.2T

Features:

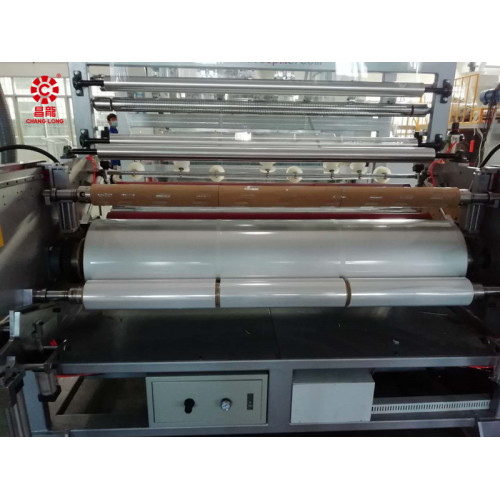

1. The alloy screw adopts special mixing refining function and high plasticity design , this unit consists of import static state mixer to ensure good plasticity and high quality output.

2. The bi-directional loop design and helix runner inside cooling steel roller is adopted to ensure even temperature of roller surface.

3. Winding roller frame adopt frame adopt aisle-platform, it`s easy to test and adjust the thickness of film, and change the slitter without stopping the machine.

4. The winding system apply air knife online device, which can automatic cut different thickness film.

Packing:

Certificate:

Related Keywords