Plastic Film Stretch Cling Film Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Productivity: | 280kg/ h |

| Supply Ability: | 20-30 sets/ month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE, ISO9001:2008 |

| Transportation: | Ocean |

Machine specification

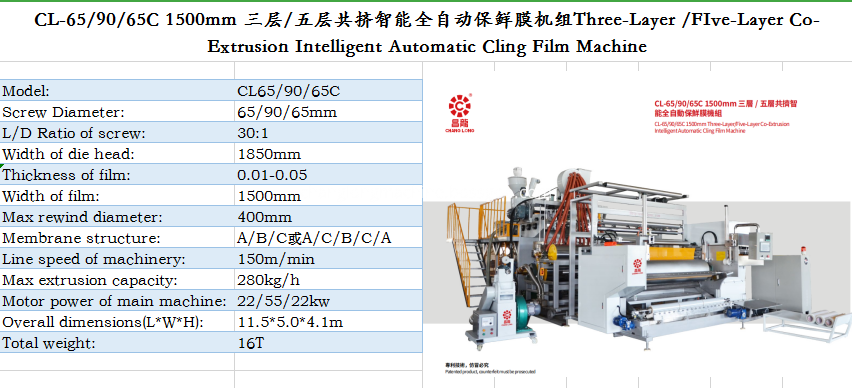

CL-65/90/65C 1500mm Three-Layer /FIve-Layer Co-Extrusion Intelligent Automatic Cling Film Machine

Advantages

★ Edge material Using online independent traction devices

★ Winding roll: Use the high quality steel and special processing gush arenaceous (make films produced when coiling bubble natural ruled out)

★ Automatic material cutting and coil changing device (patented technology), safe and reliable.

★ The cooling roller adopts the double-layer circulation cooling system with

large diameter, many inner helical ways make the temperature of the roller equally,highly improved the cooling effect and cooling speed.

★ Air Shaft automatic upper and return: The device is designed meticulously by our company, to apply for a patent and the patent department, make the heavy air shaft automatic upper and return, simple, easy to operate,save artificially, improve work efficiency.

★ Melt pump metering system with Italy Gefran pressure sensor and pressure gauge systems. Which can exactly control the melt extrusion each minute and the pressure, then control the precision and stable the extrusion. Make the film more good puncture resistance,strong tensile-strength. Save MLLDPE Production cost.

★ Mechanical automatic loading and unloading paper tube (patent technology):

automatic online push the finished production, loading the paper tube, pipeline operation,greatly reduce the labor intensity, the maximum improves the work efficiency

Application

The film can be widely used in wrapping of pallet packaging,storage packaging,manual packaging and so on.

Characteristic:

1.The cooling roller adopts a large-diameter special flow path roller to improve he cooling effect in high-speed production and ensure uniform temperature of the surface of the cooling roller.

2.The special alloy screw design adopts high plasticization and crystal point treatment structure to ensure that the extruded film is more stable,uniform,high transparency, strong tensile force and better viscosity.

3.The entire production line realizes fully automated production.On the basis of the original automatic material change and reeling , the auotomatic paper feeding tube and the automatic unloading finished system are added to ensure high quality and stable production , which greatly saves the labor cost of production.

4.The whole machine parts and electrical control parts are made of domestic and foreign famous brand products to ensure stable operation and low failure rate.

5. The unit uses melt metering pump technology with a precision sensing force system for stable and efficient pressure control ,which greatly increases the longitudinal and lateral tensile forces of memberance and the puncture resistance of the membrane. Make the finished product more rigorous to meet the strict requirements of the machine film.

Certificate

The company is a national high-tech enterprises

This product has passed the CE certification and ISO certification

Product Package

Seller provides the simple pearl wool with film package & wooden motherboard.

Client Cooperation

The sales network covers more than 80 countries and regions around the world.

After-Sales Service

The seller freely provides the fittings during the warranty for 12 months with maintenance

forever when the equipment is tested OK(Human factor and force irresistant factor exception).

Related Keywords