CL-70/100/70A PE Plastic Sheet Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 380kg/h |

| Supply Ability: | 20-30sets/m |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

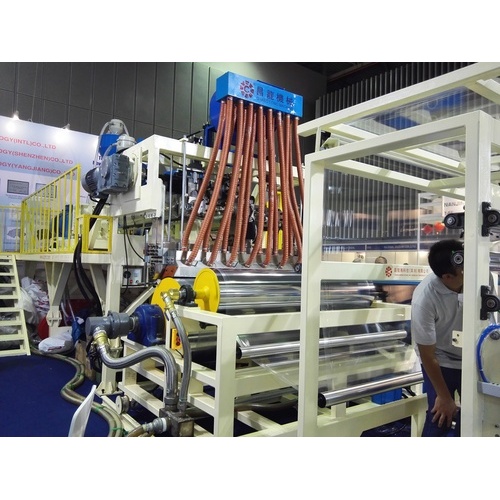

CL-70/100/70A PE Plastic Sheet Machine

Main Technical Parameter of CL-70/100/70A PE Plastic Sheet Machine:

Model: CL-70/100/70A

Width of PE Plastic Sheet: 1500mm

Thickness of Film: 0.01-0.05mm

Width of Die Head: 1850mm

Structure of PE Plastic Sheet Machinery: A/B/C or A/C/B/C/A

Liner Speed of PE Plastic Sheet Unit: 200m/min

Max Extrusion Capacity: 380kg/h

Overall Dimensions(L*W*H): 11.5*4.3*4.5m

Total Weight : 18.2T

Motor Power of PE Plastic Sheet Machinery: 37/90/37kw

Total Power of PE Plastic Sheet Unit: 50-220kw

Max Rewind Diameter: 400mm

Screw Diameter: 70/100/70mm

L/D Ratio of Screw: 30:1

This PE Plastic Film Machine CL-70/100/70A is designed based on our long time manufacturing experience and customer's actual feedback, as well as the application of the combination of Italy and Amercian high technology to produce high plasticity stretch wrapping film.It is designed for three or five layers stretch film , cling film , and protective film and this PE Plastic Film Machinery is very easy to operate.

Special Features for CL-70/100/70A PE Plastic Sheet Machine

1.Melt metering pump unit is equipped with this PE Plastic Film Making Machine and it applys the technology of precise sensor to control the extrusion pressure of this PE Plastic Film Machinery to achieve a stable extrusion flow which improves the capacity a lot.

2.Vacuum devices is applied to increase the cooling effect of the first cooling roller as it absorbs the hot air away from the surface of cooling roller and in this way, the cooling roller of this PE Plastic Film Making Unit can remain low temperature all the time, which in return helps improve the quality of product film.

3.The installation of fence around the screw stairs is designed at the aim of achieving user friendly and in this way,the operation pocess will be much safe and can also gurantee the safety of operator.

4.The PE Plastic Film Unit is controlled through Simens PLC using touch screen which is interpersoal friendly and can be operated simplely and the wrapping film unit will be more intelligent.

5.Two large cooling roller of this PE Plastic Film Machine is equipped for better cooling effect.

Certificate of CL-70/100/70A PE Plastic Sheet Machine

After-Sales Service for CL-70/100/70A PE Plastic Sheet Machine

We possess a professional technical team which enables our service net covering all around the world.The rapid and convenient service will meet your demands.

1. Senior engineer installation guide & operator training.

2.Technical service team , 7*24h telephone service.

3.12 months warranty period , lifelong maintenance services , engineer to door maintenance.

Related Keywords

-

2000mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

2000mm Three-Layer Automatic Swing Arm High-Speed Stretch Film Machine

2000mm Three & Five-Layer High-Speed Four Shafts Roll Changing Intelligent Temperature Control Automatic Casting Film Machine

New Type Four-Shafts Roll Changing Casting Film Machine

Intelligent Automatic High-Speed Casting Film Machine