1500MM PE Stretch Film Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 80 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 460kg/h |

| Supply Ability: | 30-50sets/y |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

PE High Speed Machine For Stretch Film

Features

1.Screw is adopted Special mixing function and high plasticizing capacity design,

to ensure good plasticizing, uniformity color and luster.

2.High quality ceramic heater which keep warm and keep the heater in a suitable temperature to guarantee the plastizing,when the temperature becomes higher,the fans will start to work ,to make the screw be cool.

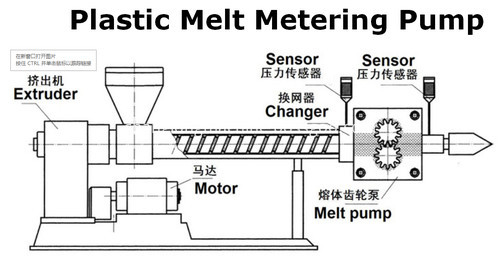

3.Melting Pump--Plastic melt metering pump is more and more important in extrusion process, especially in high-end products industries, such as high quality sheets, pipes, BOPP, optical cable.

Installing the melt metering pump in the cast stretch film unit, which can keep the production constantly and efficiency. The pump can improve the product quality, stable the production and decrease the energy consume.

The housing is made of chromium-nickel alloy or nickel-base alloy, titanium alloy. The gear is made of quenching chromium steel, other metal materials are also applicable. Bearing is made of graphite NIAG, zirconium oxide or quench tool steel.

Advantages:

FAST AND STABLE FLOW SUPPLY

Eliminated the extruder`s pulsation wave. Improve the product quality, decrease the defective rate, and decrease the waste, which can save 2% material and 25% of the unit power consumption.

STABLE AND EFFICIENCY PRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after install the melt pump, the max pressure wave value is the pressure after pump. Which can make the inner pressure of the extruder decrease, the melt shear strength decrease, the temperature curve gently, and restrain the temperature rising. Also the melt pump can avoid the damage to the extruder from the high pressure.

Application

The film can be widely used in wrapping of pallet packaging, storage packaging, manual packaging and so on.

Certificate

Packaging

After-Sales Service

We possess a professional and young management and technicial team, our service net covers all around the world, the rapid and convenient service will meet your demands.

1. 12 months warranty period , lifelong maintenance services , engineer to door maintenance.

2. Senior engineer installation guide & operator train.

3. Machine instruction , ready access.

4. Technical service team , 7*24h telephone service.

Related Keywords

-

2000mm Three-Layer/Five-Layer Co-Extrusion Intelligent Automatic High-Speed Casting Film Machine

2000mm Three-Layer Automatic Swing Arm High-Speed Stretch Film Machine

2000mm Three & Five-Layer High-Speed Four Shafts Roll Changing Intelligent Temperature Control Automatic Casting Film Machine

New Type Four-Shafts Roll Changing Casting Film Machine

Intelligent Automatic High-Speed Casting Film Machine