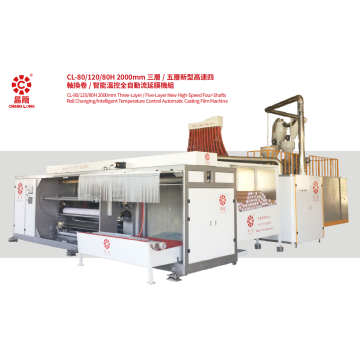

1500mm High Speed Co-extrusion Stretch Film Machine Unit

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 85 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

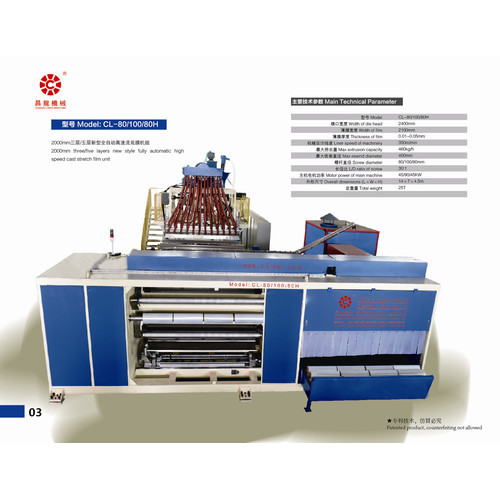

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 460kg/h |

| Supply Ability: | 1-50 sets |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,CE |

| Transportation: | Ocean,Land |

1500MM High Speed PE Cast Stretch Film Machine,Co-Extruded

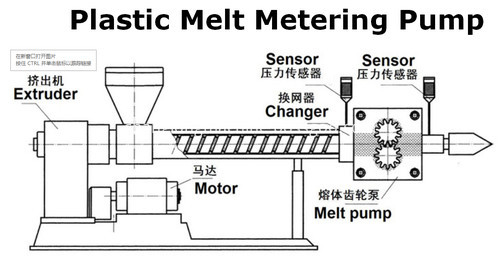

Plastic Melt Pump

Installing the melt metering pump in the cast stretch film unit, which can keep the production constantly and efficiency. The pump can improve the product quality, stable the production and decrease the energy consume.

The housing is made of chromium-nickel alloy or nickel-base alloy, titanium alloy. The gear is made of quenching chromium steel, other metal materials are also applicable. Bearing is made of graphite NIAG, zirconium oxide or quench tool steel.

Advantages:

FAST AND STABLE FLOW SUPPLY

Eliminated the extruder`s pulsation wave. Improve the product quality, decrease the defective rate, and decrease the waste, which can save 2% material and 25% of the unit power consumption.

STABLE AND EFFICIENCY PRESSURE CONTROL

The melt pump can provide a stable pressure, which short the discharge time obviously and make the production effectively.

INCREASE THE EXTRUDER OUTPUT AND THE MACHINE LIFE

It has been found that after install the melt pump, the max pressure wave value is the pressure after pump. Which can make the inner pressure of the extruder decrease, the melt shear strength decrease, the temperature curve gently, and restrain the temperature rising. Also the melt pump can avoid the damage to the extruder from the high pressure.

Application

The film can be widely used in wrapping of pallet packaging, storage packaging, manual packaging and so on.

Related Keywords