Two-Layer/Tri-Layer Automatic Preservative Film Unit

- Payment Type:

- L/C, T/T

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 135kg/h |

| Supply Ability: | 20-50sets/m |

| Payment Type: | L/C,T/T |

| Certificate: | CE,ISO90001:2008 |

| Transportation: | Ocean |

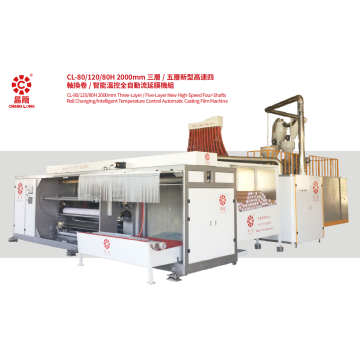

Two-Layer/Tri-Layer Automatic Preservative Film Unit

This PE preservative film unit uses automated rewinding, change roller, edge recycling system to keep the film thickness made by this kind of machine was uniformity, smooth and solid, according to a certain ratio that mix a variety of polyethylene materials and through extruding machine produced preservative film, which can anti-fog, anti-loose, rainproof, anti-dust, self-sticky, anti-piercing and so on excellent features, it's safety and envionmental protection, healthy, reliable, non-toxic harmless, it is widely used in supermarket, hotel, restaurants and other places.

Main Technical Parameters:

Model: CL-55/70A

Width of Die Head: 1250mm

Width of Film: 1000mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B or A/B /C

Liner Speed of Machinery: 120m/min

Max Extrusion Capacity: 135kg/h

Max Rewind Diameter: 400mm

Screw Diameter: 55/70mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine: 15/22kw

Total Power: 13-70kw

Overall Dimensions(L*W*H): 7.3*4*3.6m

Total Weight: 8T

The Cooling rolleris bi-directional loop design and helix runner inside cooling steel roller to ensure the same temperature of roller surface.

Optional configuration:

1) Touch screen to control electric systerm.

2) Manipulator equipment to change the roll and put the finished products down the ground.

3) Air knife to cut the film for thickness more than 50um.

4) Auto thickness measurement and auto thickness adjustment T-die.

Application

The stretch film making by this machine is used for packaging goods, uncooked food, meat, vegetable and fruit and seafood ets. In supermarket, hotel, dinning-hall and food factory.

Workshop

Certificate

Plastic Machine PE Stretch Film Machine passes CE certificate, most professional, high output!

Packing

After-Sales Service

Our professional engineering team is constitutive of excellent technical staff. We can provide perfect after-sales service in time, give a good technical training to ensure the product in best state perennially.

We will respond to customer`s service requests and complaint in the shortest possible time, give a clear reply and solution to deal with in time. At the same time, we sum up customer`s complaint and proposal in order to inherit our advantages, correct our inadequate. We will commit to improve our services quality, so that our customers will be most satisfied.

We offer warranty on product quality and lifelong maintenance services.

Related Keywords