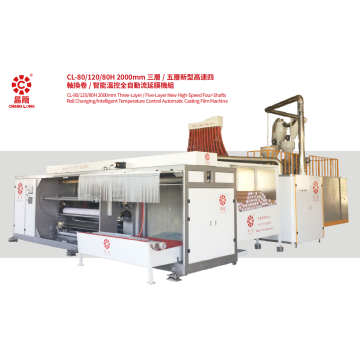

Co-extruding PE Stretch Film 1000mm Casting Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 135kg/h |

| Supply Ability: | 20-50sets/m |

| Payment Type: | T/T |

| Certificate: | CE,ISO90001:2008 |

| Transportation: | Ocean |

1000mm Co-extruding PE Stretch Film Casting Machine

This powerful machine is designed to produce high-quality polyethylene (PE) stretch film, ideal for a range of packaging applications. With a 1000mm production width, it's perfect for businesses aiming to efficiently produce large quantities of film.

Key Features and Benefits

Co-extrusion Technology: This advanced technology provides precise control over layer thickness and material composition, resulting in films with superior strength, clarity, and durability. Whether you need films like those produced by the 1000MM Black Stretch Film Machine Unit for specific applications, or standard options, we've got you covered.

High-Speed Production: The machine's high-speed capability ensures you can meet demanding production schedules with ease.

Efficient Operation: The automated system reduces manual intervention, cutting labor costs and boosting productivity. This efficiency is comparable to that offered by the 1000MM Hand Stretch Film Machine Unit for manual or semi-automatic operations.

Customizable Film Properties: By adjusting the layer thickness and material composition, you can customize the film's properties to meet specific requirements, such as increased strength, improved clarity, or enhanced puncture resistance, akin to outputs from the 1000MM Plastic Stretch Film Machine Unit.

How It Works

The machine uses a co-extrusion process to merge multiple layers of molten plastic resin into a single, high-performance film. These layers are extruded through a die, then cooled and solidified on a casting drum.

Ideal Applications

Packaging: Protecting products during storage and transportation, similar to the robust film applications of the 1000MM Packaging Stretch Film Machine Unit.

Food Packaging: Wrapping food products to maintain freshness and prevent contamination.

Industrial Packaging: Securing heavy-duty items for storage or transportation.

Upgrade Your Packaging Process

Invest in this state-of-the-art machine to elevate your packaging process to new heights. With its advanced features and efficient operation, you can reduce costs, improve productivity, and produce high-quality films that will ensure your products remain safe and secure. Whether you're seeking a 1000MM Hand Stretch Film Machine Unit for customized manual applications or a high-capacity solution like the 1000MM Packaging Stretch Film Machine Unit, our equipment provides the versatility your business needs.

Features:

1. The alloy screwadopts special mixing refining function and high plasticity design to ensure good plasticization, good transparency and greatly improving the capacity.

2.T-Die adoptimport top speical mould steel, which professional materials on PE plasticity. By our high precision process and treatment to ensure the long service life of T-Die without any deformation.

3. The Cooling rolleris bi-directional loop design and helix runner inside cooling steel roller to ensure the same temperature of roller surface.

Machine Specification:

1.The fit materials: LLDPE

2. PLC Automatic roll changer, automatic filter changer,

3.Automatic loader and auto edge film recycling unit.

4.150CC gear pump and American sensor system to control the extruder output at 100% uniformity,which make the film more uniformty, good tensile strenth and good anti- puncture.

Co-extruding PE Stretch Film 1000mm Casting Machine CL-55/70A

Main Technical Parameter

Width of Die Head: 1250mm

Width of Film: 1000mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B or A/B /A

Liner Speed of Machinery: 120m/min

Max Extrusion Capacity: 135kg/h

Max Rewind Diameter: 400mm

Screw Diameter: 55/70mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine: 15/22kw

Overall Dimensions(L*W*H): 7*3*3.6m

Total Weight: 8T

Optional configuration:

1) Touch screen to control electric systerm.

2) Manipulator equipment to change the roll and put the finished products down the ground.

3) Air knife to cut the film for thickness more than 50um.

4) Auto thickness measurement and auto thickness adjustment T-die.

Application

The stretch film making by this machine is used for packaging and storing cooked food, uncooked food, meat, vegetable and fruit and seafood ets. In supermarket, hotel, dinning-hall and food factory.

Related Keywords