1000mm Three Layers Stretch Film Making Machine

- Payment Type:

- L/C, T/T

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 135kg/h |

| Supply Ability: | 20-50sets/m |

| Payment Type: | L/C,T/T |

| Certificate: | CE,ISO9001:2008 |

| Transportation: | Ocean |

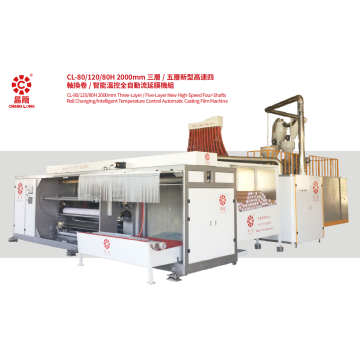

CE Standard 1000mm Three Layers Stretch Film Making Machine

Stretch film machine mainly use LLDPE,LDPE or recycled LLDPE material to produce one side sticky or 2 sides sticky stretch film,cling film,cast stretch film etc.The width from 20mm to 2000mm, single layer to 2 layers, 3 layers, 5 layers and so on.

This Unit is based on our long time manufacturing experience and customer's actual operate, Combine with Italy and Amercian high-tech to produce high plasticity, easy to operate, long life and power saving machine.This machine is fit for making stretch film, cling film and protecting film.

Main Technical Parameter:

Model: CL-55/70A

Width of Die Head: 1250mm

Width of Film: 1000mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B or A/B /C

Liner Speed of Machinery: 120m/min

Max Extrusion Capacity: 135kg/h

Max Rewind Diameter: 400mm

Screw Diameter: 55/70mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine: 15/22kw

Total Power: 13-70kw

Overall Dimensions(L*W*H): 7.3*4*3.6m

Total Weight: 8T

Machine Specification:

1- The fit materials: LLDPE

2- PLC Automatic roll changer, automatic filter changer,

3-Automatic loader and auto edge film recycling unit.

4-150CC gear pump and American sensor system to control the extruder output at 100% uniformity,which make the film more uniformty, good tensile strenth and good anti- puncture.

Features:

1- The alloy screwadopts special mixing refining function and high plasticity design to ensure good plasticization, good transparency and greatly improving the capacity.

2-T-Die adoptimport top speical mould steel, which professional materials on PE plasticity. By our high precision process and treatment to ensure the long service life of T-Die without any deformation.

3- The Cooling rolleris bi-directional loop design and helix runner inside cooling steel roller to ensure the same temperature of roller surface.

Optional configuration:

1) Touch screen to control electric systerm.

2) Manipulator equipment to change the roll and put the finished products down the ground.

3) Air knife to cut the film for thickness more than 50um.

4) Auto thickness measurement and auto thickness adjustment T-die.

Application

The stretch film making by this machine is used for packaging and storing cooked food, uncooked food, meat, vegetable and fruit and seafood ets. In supermarket, hotel, dinning-hall and food factory.

Workshop

Certificate

Plastic Machine PE Stretch Film Machine passes CE certificate, most professional, high output!

Packing

Exhibitions

After-Sales Service

Our professional engineering team is constitutive of excellent technical staff. We can provide perfect after-sales service in time, give a good technical training to ensure the product in best state perennially.

We will respond to customer`s service requests and complaint in the shortest possible time, give a clear reply and solution to deal with in time. At the same time, we sum up customer`s complaint and proposal in order to inherit our advantages, correct our inadequate. We will commit to improve our services quality, so that our customers will be most satisfied.

We offer warranty on product quality and lifelong maintenance services.

Related Keywords