Equipment For Fluorescent Penetrant Inspection Process

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 600 |

| Supply Ability: | 50 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Certificate: | CE ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Product Description

Product Description

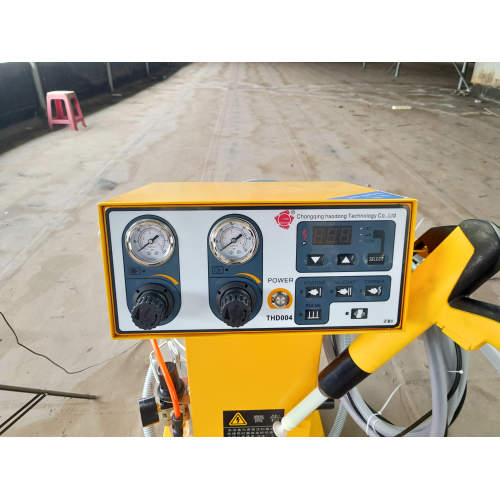

Intelligent high pressure duster

CHRACTERISTIC

1.Bright white

2. Simple operation

3. Color diversity

4. Good anticorrosion

5. Quick reaction time

6. Increased adhesion

7. Specular effect

8, low temperature can be normal production

9. Add additives and activators

10. The technology is easy to learn and master.

The process flow

1, substrate surface treatment, plastic surface to conduct electrostatic dust removal; The iron material should be treated with phosphate surface treatment.2, spray primer, surface requirements of high flatness and cleanliness.

3. Dry, make sure the primer is thoroughly dry.

4, stand, primer surface to avoid dust, thoroughly cool.

5. Spray the surfactant and adjust the surface tension to provide conditions for the formation of uniform silver mirror film.

6, clean pure water, thoroughly clean, remove the excess surfactant.

7. Chemical reaction to form a homogeneous mirror.

8. Rinse thoroughly with pure water to remove excess reaction liquid.

9. Stabilizer to enhance the oxidation resistance of the metal layer.

10. Procedure: Air drying, surface moisture removal, no water accumulation on the silver mirror surface.

11, procedures: dry, dry water, enhance the adhesion of the coating.

12, transparent coating, according to the product color requirements can be added transparent.

DETAILS

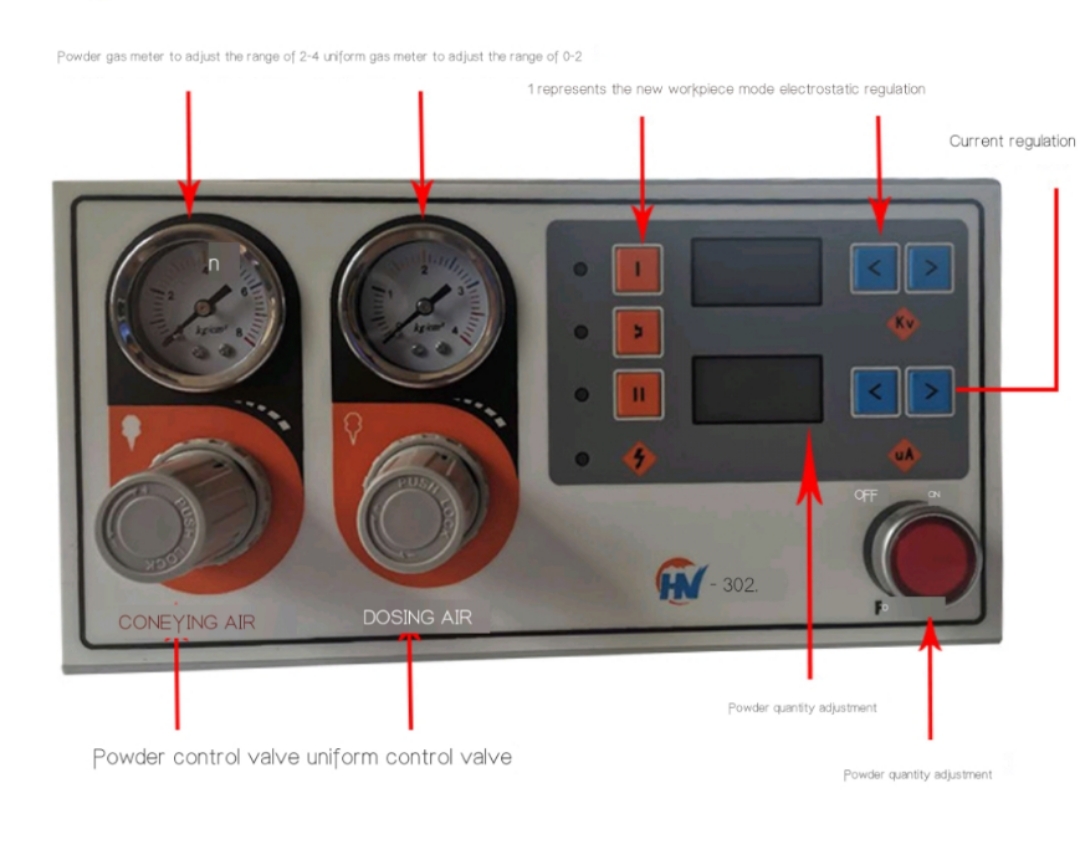

1.Original manufacturer customized pump headEven powder, powder on good, save powder

2.Fluidization adjustment at bottom of powder bucket

Can adjust the amount of fluidization, to the powder in the powder drum in the drum for the fluidization standard

FAQ

Q1. Can I have a sample order for plastic painting machine?A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7 days, mass production time needs 2-3 weeks for order quantity more than

Q3. Do you have any MOQ limit for coating machine order?

A: Low MOQ, 1set for sample checking is available

OUR CERTIFICATION

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 quality control system, CE certificate, etc.

Related Keywords

Related Keywords