automatic powder curing oven

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | SHENZHEN |

|---|---|

| Productivity: | 15 |

| Supply Ability: | 5 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Certificate: | ISO |

| Transportation: | Ocean |

| Port: | SHENZHEN |

Product Description

Product Description

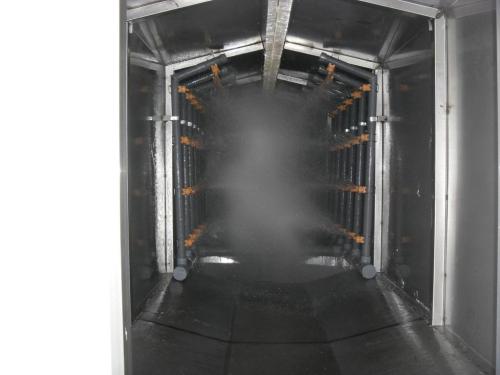

In electrostatic powder coating, the curing oven is a relatively important device, and the quality of the film has a very important relationship with the temperature of the curing oven. In the heating mode of the powder curing furnace, it can be divided into two categories: one is hot air circulation type, and the second type is infrared radiation heating method.

The hot air circulation heating type can be divided into direct heating and indirect heating. There are two kinds of heat sources for direct heating, electric heating spiral fin type and gas type direct heating method. The advantage of direct electric heating spiral fin type is that the temperature inside the furnace is uniform and the workpiece adaptability is strong: the temperature is adjusted by the solid state relay PID, and the temperature deviation in the furnace is small. The disadvantage is that the heating time is slow and the equipment power is large. Because it is heated by hot air circulation, the curing process is liable to cause secondary pollution of dust. The stove has a large area.

The advantages of the gas-fired direct heating method are rapid heating rate, high heat energy conversion rate, and the furnace temperature control adopts proportional adjustment control. The temperature control deviation in the warm furnace is small, because the burner flame directly burns in the combustion chamber, so the curing process is easy to cause For secondary pollution of dust and exhaust gas, a high-temperature resistant filter should be installed in the heating chamber. Therefore, the full pressure of the circulating fan should be considered larger in the selection of the fan. In addition, the stainless steel plate must be used to heat the indoor plate. Increase, the furnace covers a large area.

Two indirect heating methods Indirect heating of two types of fuel oil. The characteristics of indirect combustion heating method, there must be a heat exchange device, the terminology is called heat exchanger, the flame of the burner is burned in the furnace of the heat exchanger, so the material of the heat exchanger should be made of heat-resistant stainless steel (usually SUS310S) Material thickness can not be less than 5mm), the advantage of indirect heating method, because the burner flame burns in the heat exchanger, so that it will not cause secondary pollution of dust and exhaust gas during the curing process, the temperature is uniform, and the temperature control can adopt two-stage fire control and Proportional adjustment control. The control temperature is relatively accurate. The disadvantage of the indirect heating method is that because of the heat exchange through the heat exchanger, the thermal efficiency is lower, the installation cost is relatively high, and the furnace covers a large area. Infrared direct heating can be divided into far infrared and high infrared. Far-infrared heating is well known to the world. When the radiation spectrum of the far-infrared heating element is the same as the absorption spectrum of the heated workpiece, the thermal efficiency is the highest, thereby achieving energy saving. The advantage of the far-infrared heating method is that the radiation spectrum directly absorbed by the powder during the heating process causes the powder on the surface of the workpiece to rapidly solidify. The furnace has a small footprint, but the furnace temperature uniformity of the far-infrared heating method is not good, so the current design is solved by the circulation fan stirring method.

The radiation spectrum of the heater during high-infrared heating is absorbed by both the workpiece and the powder, so that the workpiece and the powder are simultaneously heated, so that the powder is solidified faster, thereby saving energy. The general high-infrared heating products are mostly made of glass, which is easy to damage during installation. The high infrared heater has a short life span, and its working life is about 5,000 hours to 8,000 hours

The hot air circulation heating type can be divided into direct heating and indirect heating. There are two kinds of heat sources for direct heating, electric heating spiral fin type and gas type direct heating method. The advantage of direct electric heating spiral fin type is that the temperature inside the furnace is uniform and the workpiece adaptability is strong: the temperature is adjusted by the solid state relay PID, and the temperature deviation in the furnace is small. The disadvantage is that the heating time is slow and the equipment power is large. Because it is heated by hot air circulation, the curing process is liable to cause secondary pollution of dust. The stove has a large area.

The advantages of the gas-fired direct heating method are rapid heating rate, high heat energy conversion rate, and the furnace temperature control adopts proportional adjustment control. The temperature control deviation in the warm furnace is small, because the burner flame directly burns in the combustion chamber, so the curing process is easy to cause For secondary pollution of dust and exhaust gas, a high-temperature resistant filter should be installed in the heating chamber. Therefore, the full pressure of the circulating fan should be considered larger in the selection of the fan. In addition, the stainless steel plate must be used to heat the indoor plate. Increase, the furnace covers a large area.

Two indirect heating methods Indirect heating of two types of fuel oil. The characteristics of indirect combustion heating method, there must be a heat exchange device, the terminology is called heat exchanger, the flame of the burner is burned in the furnace of the heat exchanger, so the material of the heat exchanger should be made of heat-resistant stainless steel (usually SUS310S) Material thickness can not be less than 5mm), the advantage of indirect heating method, because the burner flame burns in the heat exchanger, so that it will not cause secondary pollution of dust and exhaust gas during the curing process, the temperature is uniform, and the temperature control can adopt two-stage fire control and Proportional adjustment control. The control temperature is relatively accurate. The disadvantage of the indirect heating method is that because of the heat exchange through the heat exchanger, the thermal efficiency is lower, the installation cost is relatively high, and the furnace covers a large area. Infrared direct heating can be divided into far infrared and high infrared. Far-infrared heating is well known to the world. When the radiation spectrum of the far-infrared heating element is the same as the absorption spectrum of the heated workpiece, the thermal efficiency is the highest, thereby achieving energy saving. The advantage of the far-infrared heating method is that the radiation spectrum directly absorbed by the powder during the heating process causes the powder on the surface of the workpiece to rapidly solidify. The furnace has a small footprint, but the furnace temperature uniformity of the far-infrared heating method is not good, so the current design is solved by the circulation fan stirring method.

The radiation spectrum of the heater during high-infrared heating is absorbed by both the workpiece and the powder, so that the workpiece and the powder are simultaneously heated, so that the powder is solidified faster, thereby saving energy. The general high-infrared heating products are mostly made of glass, which is easy to damage during installation. The high infrared heater has a short life span, and its working life is about 5,000 hours to 8,000 hours

Related Keywords

Related Keywords