Automatic electrostatic powder spraying equipment

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | SHENZHEN |

|---|---|

| Productivity: | 15 |

| Supply Ability: | 5 |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO |

| Transportation: | Ocean |

| Port: | SHENZHEN |

Product Description

Product Description

Hengyijia Automation can provide automatic spraying of the entire factory and automatic spraying of manual spraying.

The line body operation mode can also be divided into: tracking continuous painting or step-type painting, the workpiece rotation mode is not rotated, 90°, 360°.

Spray line production structure:

Manual upper and lower parts, automatic conveying line, manual dust removal/electrostatic automatic dust removal, preheating dehumidification, automatic spraying equipment (reciprocating machine, robot, etc.), purification workshop, paint mist exhaust system, constant temperature and humidity air supply system, high efficiency pressure equalization box , product surface leveling, drying, cooling system, central control system, waste water treatment system, etc.

Spray line details:

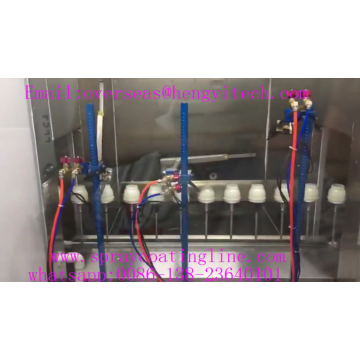

Spraying method: select reasonable automatic spraying equipment (reciprocating machine, robot, etc.) according to the spraying range of the product and the number of spray guns;

Delivery method: suspension line

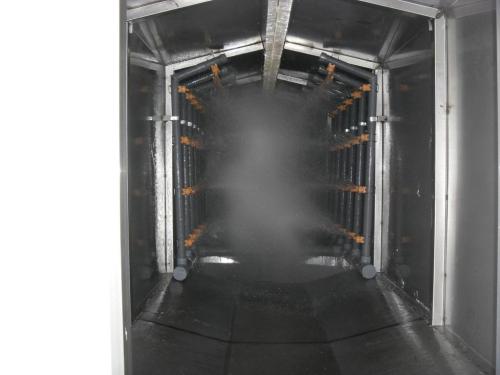

Spraying environment: spray paint cabinet adopts water curtain type or dry type, 10,000 grade, 100,000 class dust-free spraying room, and is sent into the spray booth through high-efficiency air supply port; constant temperature and humidity;

Baking method: tunnel oven, precision oven, far infrared heating IR tube, uv curing;

Exhaust gas treatment: spraying and discharging after activated carbon filtration;

Production: depending on the tooling method of the workpiece and the baking time of the coating combined with the line speed and other factors;

Adapt to the workpiece: plastic, hardware, wood products, glass, ceramics, magnets and other products surface painting treatment;

Automatic fuel injection line process: feeding - manual electrostatic precipitator - material preheating - automatic electrostatic precipitator - automatic primer spraying - leveling - standing - baking - cooling - blanking

Technical Parameters

Automatic spraying production line body structure: can be designed as one coating one roast, two coating two roasting, three coating three roasting (according to customer requirements)

Conveying mode: automatic rail transportation (can be customized according to customer requirements) conveying speed adjustable design speed 2.5m/min

Spraying method: painting robot

Baking method: infrared electric heating drying + ultraviolet uv curing

Purification method: using color steel plate partition wall, adopting green leveling epoxy ground

Air supply system: for fresh air system, and outdoor air exhaust system

Toys, plastic shell industry: Christmas balls, decorations, cosmetic bottles, toys, etc.;

Sports, office equipment industry: golf balls, printer rollers, clubs, helmets, soles, masks, ski equipment, skating equipment, surfboards, electronic keyboards, etc.;

Hardware daily necessities, kitchen utensils industry: bearings, saw blades, stainless steel plates and other hardware; hair dryers, air conditioners / televisions and other daily necessities;

Bathtubs and other toiletries; kettles and other kitchen utensils; fire extinguishers, helmets and other security products; thermometers, stethoscopes and other medical equipment;

Power industry: power capacitors, motors, transformers, generators, power switches, shafts, resistors, etc.;

The line body operation mode can also be divided into: tracking continuous painting or step-type painting, the workpiece rotation mode is not rotated, 90°, 360°.

Spray line production structure:

Manual upper and lower parts, automatic conveying line, manual dust removal/electrostatic automatic dust removal, preheating dehumidification, automatic spraying equipment (reciprocating machine, robot, etc.), purification workshop, paint mist exhaust system, constant temperature and humidity air supply system, high efficiency pressure equalization box , product surface leveling, drying, cooling system, central control system, waste water treatment system, etc.

Spray line details:

Spraying method: select reasonable automatic spraying equipment (reciprocating machine, robot, etc.) according to the spraying range of the product and the number of spray guns;

Delivery method: suspension line

Spraying environment: spray paint cabinet adopts water curtain type or dry type, 10,000 grade, 100,000 class dust-free spraying room, and is sent into the spray booth through high-efficiency air supply port; constant temperature and humidity;

Baking method: tunnel oven, precision oven, far infrared heating IR tube, uv curing;

Exhaust gas treatment: spraying and discharging after activated carbon filtration;

Production: depending on the tooling method of the workpiece and the baking time of the coating combined with the line speed and other factors;

Adapt to the workpiece: plastic, hardware, wood products, glass, ceramics, magnets and other products surface painting treatment;

Automatic fuel injection line process: feeding - manual electrostatic precipitator - material preheating - automatic electrostatic precipitator - automatic primer spraying - leveling - standing - baking - cooling - blanking

Technical Parameters

Automatic spraying production line body structure: can be designed as one coating one roast, two coating two roasting, three coating three roasting (according to customer requirements)

Conveying mode: automatic rail transportation (can be customized according to customer requirements) conveying speed adjustable design speed 2.5m/min

Spraying method: painting robot

Baking method: infrared electric heating drying + ultraviolet uv curing

Purification method: using color steel plate partition wall, adopting green leveling epoxy ground

Air supply system: for fresh air system, and outdoor air exhaust system

Toys, plastic shell industry: Christmas balls, decorations, cosmetic bottles, toys, etc.;

Sports, office equipment industry: golf balls, printer rollers, clubs, helmets, soles, masks, ski equipment, skating equipment, surfboards, electronic keyboards, etc.;

Hardware daily necessities, kitchen utensils industry: bearings, saw blades, stainless steel plates and other hardware; hair dryers, air conditioners / televisions and other daily necessities;

Bathtubs and other toiletries; kettles and other kitchen utensils; fire extinguishers, helmets and other security products; thermometers, stethoscopes and other medical equipment;

Power industry: power capacitors, motors, transformers, generators, power switches, shafts, resistors, etc.;

Solder mask ink industry: PCB circuit board (PCB board of various electrical appliances);

Related Keywords

Related Keywords