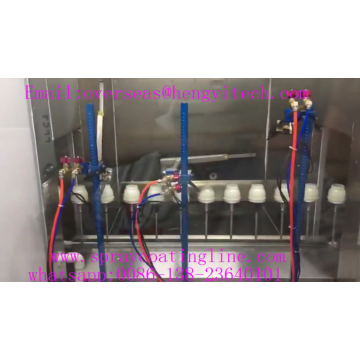

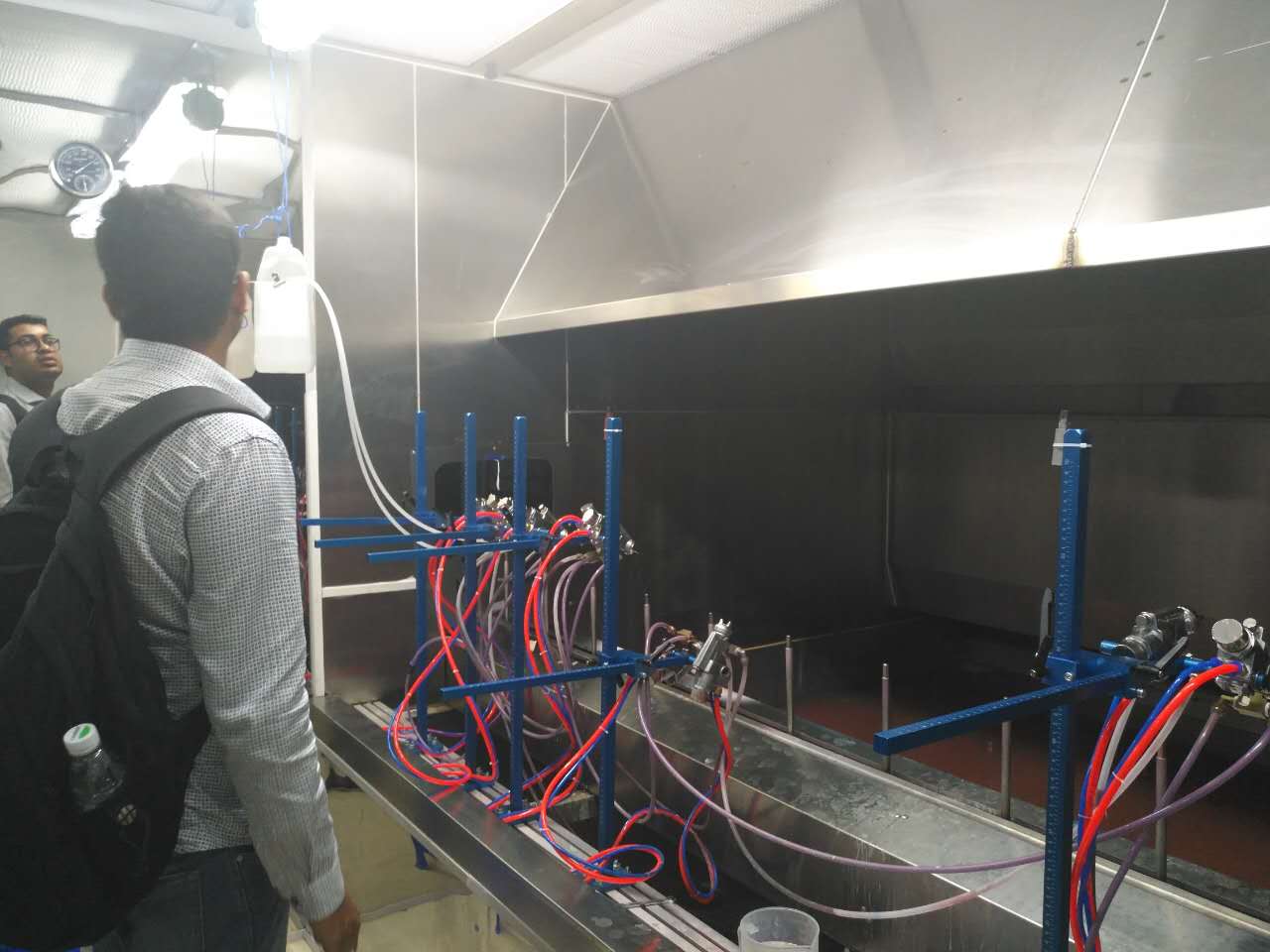

Automatic powder painting coating line

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 35 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Equipment body size

1. Equipment length: 20m work area width of 15m

2. Working area: divided into three sections: one section: loading area, two sections: spraying area, three sections: baking area four sections: cooling discharge area

3 feeding operation area: 5000mm

4. Baking operation area: 8800mm

5. Baking area and cooling area spacing: 500 mm

6. Baking area: 8800mm

7. Cooling zone: 3000mm

8. Entrance height: 600mm-800mm

9. Entrance width: 450mm

Conveyor belt from the ground: 250mm (total height of the machine 1520 ± 30mm)

Equipment main structure

The main structure of 50 * 50 mm + a channel, no bad interface (nice).

Workspace Tunnel body: 1.2mm cold plate + paint closed cold-rolled steel

Work area Tunnel cavity: 1.0mm mirror steel Model: SUS316 #

Body support: Fang Tong a model: 50 * 50 "Fang Tong

Wind system: forced to carry 4 sets of wind fans

Insulation material: vacuum aluminum silicate + silk double type: 60K

Conveyor: track hanging

10. Balance device: ground screw

Electrical equipment part: (using PLC system automation control)

1. The main switch: 80.0A

2.Total power: 70.0KW

3. Transport motor: 750W (drive speed)

4. Forced circulation fan: HYJ-375w type

5. Cooling hair dryer: HYJ-100 type

6. Ammeter: 40A 4 sets

7. Voltmeter: 400V 1 set

8. Working voltage: 380V ± 5% three-phase five-wire system 50Hz

Drying part:

1. Liner a total of 4 sections of the furnace chamber, 2.2 meters each section of the furnace, combined into a total length of 8.8 meters;

2. Furnace cavity three sides shop 50㎜ high temperature insulation layer; Beam middle shop 60mm thick insulation layer;

3. Internal heat source installed on both sides, forced air circulation, the temperature uniformity control within ± 2.5 ℃;

4. Furnace chamber with control box, the use of Japan RKC temperature controller, the temperature RT ~ + 350 ℃ arbitrary adjustable, PID self-tuning function, automatic thermostat, with over-temperature power, over-temperature alarm, leakage protection and other functions ;

5. At the top of the furnace chamber equipped with wind motor, power 370W, with nine inches wind wind wheel;

6. Configure the control panel 1 set

Four: standard configuration

1. a product manual

2. a product warranty card

Fifth, safety devices

Overvoltage and overcurrent protection

2. Fault alarm prompts

3. Equipment overload protection

4. Emergency stop protection

5. Over-temperature prevention device (to protect the test object and test box)

6. Motor (blower) overload thermal relay (to protect the blower overload)

7. Protection of the motor phase loss circuit breaker

Six, warranty period description

1) In the normal use of equipment maintenance, machine warranty for 1 year, during the warranty period by the B is responsible for free warranty.

2) During the warranty period, the non-wearing parts in the unit are damaged or invalid under normal use, and Party B will be replaced free of charge.

3) During the warranty period, Party B shall be obliged to carry out repairs regardless of any breakdown or damage to the equipment provided. Party B shall send personnel to verify on site whether the components of the equipment are normally used or not, and written reports are issued on site Clarify the reasons and reasons. Confirmed by both parties. (Man-made damage to our company to charge the appropriate fees) If our engineers and technicians have sufficient reason to prove that man-made damage and Party A refused to sign, I Division have the right to refuse to perform the maintenance within the obligation. At the same time termination of warranty. Division I no longer bear any responsibility.

Related Keywords