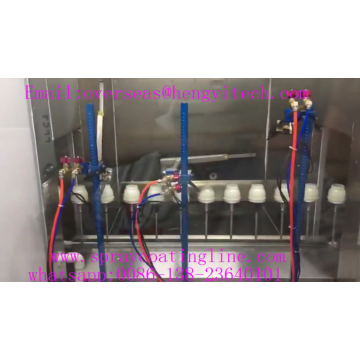

Automatic electrostatic Cabinet Powder coating equipment

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 30 |

| Supply Ability: | 5 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

Production of powder coating:

For small batch parts, the general use of manual dusting device, and for large quantities of workpieces, the general use of manual or automatic dusting device. Whether it is manual powder or automatic powder, it is very important to keep quality off. To ensure that the workpiece was sprayed with uniform powder, the same thickness, to prevent thin spray, leakage spray, wipe and other defects.

In the process of painting the production line, we should also pay attention to the hook part of the workpiece, before entering the curing, as far as possible will be attached to the powder blowing off to prevent the excess powder on the hook curing, and some cured before the powder There are difficulties, it should be promptly stripped on the hook has been cured film, so as to ensure good hook hook, in order to facilitate the next batch of easy to powder.

Painting line curing process Production management:

This process should pay attention to the following matters: spray a good workpiece, if it is a small batch of single-production, into the curing furnace before the attention to prevent falling powder, if the phenomenon of powder, should be timely filling powder. Baking strict process and temperature, time control, pay attention to prevent color, over baking or too short time caused by insufficient curing.

For large quantities of automatic delivery of the workpiece, in the boring Road before the same to carefully check whether the leak, spray or local powder phenomenon, such as the discovery of non-qualified pieces, should be good to prevent the entry into the bake Road, as far as possible to take heavy spray. Such as individual parts due to thin spray failed, in the curing of the bake Road can be re-spray again after curing.

Engineering process layout:

1, spray line: the conveyor chain - spray - drying (10min, 180 ℃ -220 ℃) - cooling - the next

2, paint line: the conveyor chain - electrostatic dust - primer - leveling - topcoat - leveling - drying (30min, 80 ℃) - cooling - the next

Painting line process is divided into: pre-treatment, dust coating, heating curing.

For small batch parts, the general use of manual dusting device, and for large quantities of workpieces, the general use of manual or automatic dusting device. Whether it is manual powder or automatic powder, it is very important to keep quality off. To ensure that the workpiece was sprayed with uniform powder, the same thickness, to prevent thin spray, leakage spray, wipe and other defects.

In the process of painting the production line, we should also pay attention to the hook part of the workpiece, before entering the curing, as far as possible will be attached to the powder blowing off to prevent the excess powder on the hook curing, and some cured before the powder There are difficulties, it should be promptly stripped on the hook has been cured film, so as to ensure good hook hook, in order to facilitate the next batch of easy to powder.

Painting line curing process Production management:

This process should pay attention to the following matters: spray a good workpiece, if it is a small batch of single-production, into the curing furnace before the attention to prevent falling powder, if the phenomenon of powder, should be timely filling powder. Baking strict process and temperature, time control, pay attention to prevent color, over baking or too short time caused by insufficient curing.

For large quantities of automatic delivery of the workpiece, in the boring Road before the same to carefully check whether the leak, spray or local powder phenomenon, such as the discovery of non-qualified pieces, should be good to prevent the entry into the bake Road, as far as possible to take heavy spray. Such as individual parts due to thin spray failed, in the curing of the bake Road can be re-spray again after curing.

Engineering process layout:

1, spray line: the conveyor chain - spray - drying (10min, 180 ℃ -220 ℃) - cooling - the next

2, paint line: the conveyor chain - electrostatic dust - primer - leveling - topcoat - leveling - drying (30min, 80 ℃) - cooling - the next

Painting line process is divided into: pre-treatment, dust coating, heating curing.

Related Keywords

Related Keywords