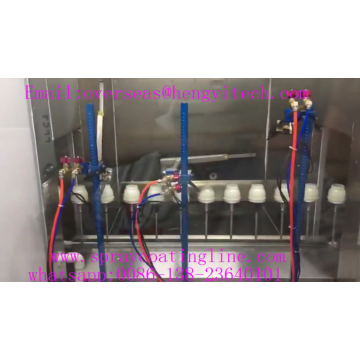

electrostatic cabinet powder coating line

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 40 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 30 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

Electrostatic spraying using high-voltage electrostatic corona electric field principle, the nozzle on the metal diversion cup connected to the high-pressure negative, the workpiece is grounded to form a positive pole, between the gun and the workpiece to form a strong electrostatic field. When the carrier gas (compressed air) to the powder coating from the supply barrel through the powder delivery pipe to the gun of the cup, because the diversion cup connected to the high-pressure negative corona discharge, the surrounding charge generated dense charge, powder Negative charge, in the electrostatic force and the role of compressed air, the powder evenly adsorbed on the workpiece, the heating, the powder melt into a uniform, smooth, smooth coating

Process flow editor

The plastic powder through the high-voltage electrostatic charging equipment, and under the action of the electric field evenly adsorbed on the workpiece surface, and then after high temperature baking, plastic particles will melt into a layer of dense protective layer firmly attached to the surface of the workpiece.

Powder electrostatic spraying line mainly contains the following process:

1, pre-treatment (degreasing, rust, phosphate);

2, electrostatic spraying;

3, high temperature curing (according to the different composition of sprayed plastic powder and the required thickness of the curing temperature is usually 160-210 degrees);

Powder coating advantages

Compared with the traditional paint process, powder coating has the following advantages:

1, efficient: because it is a one-time film, can increase the productivity of 30-40%

2, energy saving: reduce energy consumption of about 30%

3, less pollution: no organic solvent evaporation (excluding paint coatings in toluene, xylene and other harmful gases).

4, high utilization of paint: up to 95% or more, and the powder can be used after repeated use.

5, the coating performance is good: one-time film thickness of up to 50-80μm, its adhesion, corrosion resistance and other comprehensive indicators better than the paint process.

6, low yield: in the uncured before the second heavy spray can be carried out.

Automatic spray powder equipment editing

1, spraying system:

A), high voltage electrostatic generator: dedicated high voltage power supply. To produce a high-intensity electrostatic field, about 2KV / cm.

B), electrostatic powder gun: manual spray gun can achieve the purpose of uniform coating. Which the maximum amount of powder up to 350g / min.

C), for the powder barrel: the amount of about 20-100kg of powder, with a powder pump to the powder gun for continuous powder.

2, Dusting room: the workpiece for the painting operation of the studio.

3, powder recovery equipment:

Its main technical indicators: powder recovery rate> 85%. There are three main types of combinations.

A), cyclone dust collector and bag dust collector.

B), filter tube recovery (no pipe connection)

C), multi-tube small cyclone dust collector and ceramic sintered plate dust collector.

4, the other: the system is also equipped with air handling, vibration sieve, coating performance testing equipment and other devices.

Related Keywords