Powder Spray Painting Production Line

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

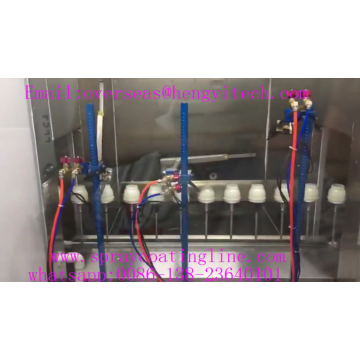

- 45 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 15 |

| Supply Ability: | 6 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001 |

| Transportation: | Ocean |

Our company can be customized according to your needs to automate the powder production line, powder line can be manual electrostatic powder or automatic electrostatic powder. Want to make a dusting equipment The lowest investment is handmade powder and fixed oven grilled powder. Investment is the middle of the manual powder automatic baking, the senior is the computer control automatic powder and conveyor line automatic baking powder.

Working Process of Aluminium Powder Coating Plant Machine

1. Feed your steel control cabinet on crane hanger for the preparation for chemical cleaning

2. Pre-degreasing stage (50-65 Celsuis for 1 min)

3. Degreasing stage (50-65 Celsuis for 2 mins)

4. Rinsing stage (Room temperature for 1-2 mins)

5. Surface conditioning stage (Room temperature for 1 min)

6. Phosphating stage (35-45 Celsuis for 3 mins)

7. Rinsing stage (Room temperature for 1-2 mins)

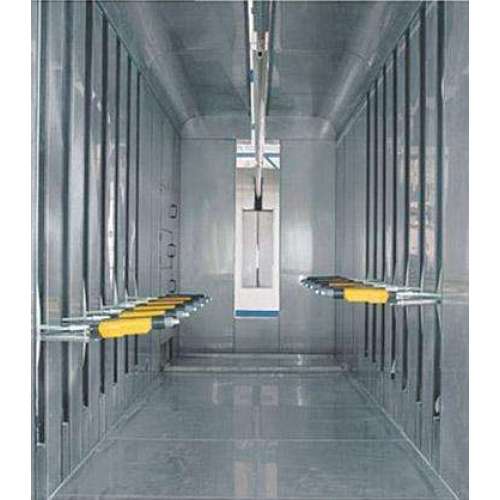

8. Drying off oven to remove surface moisture (100-120 Celsuis for 10 mins)

9. Manually transfer the pre-treated objects to powder coating line

10. Powder application with spray guns

11. Powder curing (180-200 Celsuis for 20 mins)

12. Finished product discharging

If above parameters cannot meet with your strict coating need, please contact us for more detail. We can make some adjustments or even improvements to suit your actual production conditions.

Curing oven heating ( heating energy ) selection

1. Gas hot air heating system ( full automatic ) ---- Which is preferred by box curing oven. Powder coating line continuous operation can also be selected ( Box furnace or powder coating line curing tunnel should choose gas system

2. Fuel hot air heating system ( full automatic ) ---- As oil prices rise, higher operating costs

3. Far-infrared radiation heating system ( full automatic ) --- Running costs are high, but the equipment investment is the most economical, especially small quantities spraying may be considered.

Related Keywords