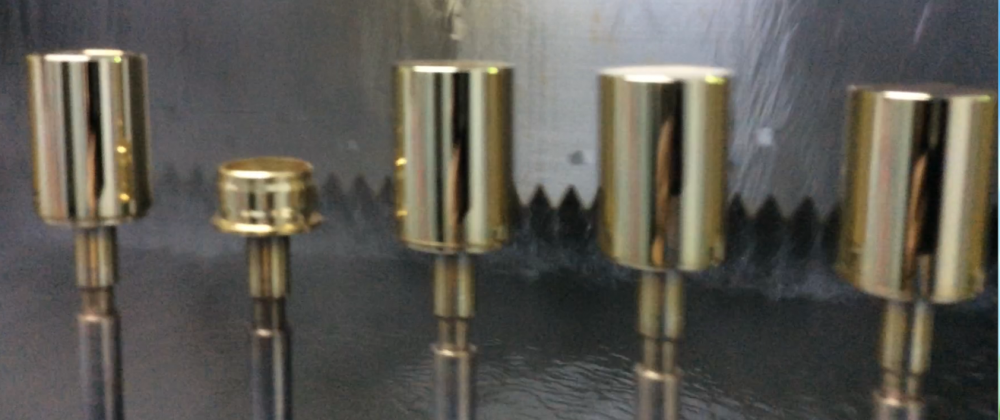

Perfume bottle cap coating line

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 36 |

| Supply Ability: | 7 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

Features Description

HENGYIJIA-UV series of automatic coating lines have advanced complete spraying system, mainly for the vacuum coating products to provide automatic humanized primer, topcoat spraying.

It can be widely applied to the UV spraying of plastic, metal, glass, ceramic and other materials. UV spraying technology has excellent surface forming ability, giving products high-density adhesion and uniform coating.

A complete line coating system, flame treatment room, electrostatic precipitator room, UV automatic spray booth, infrared preheat leveling, UV light curing, cooling air chamber.

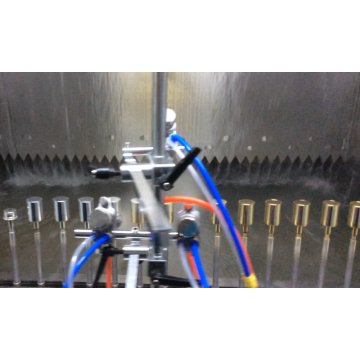

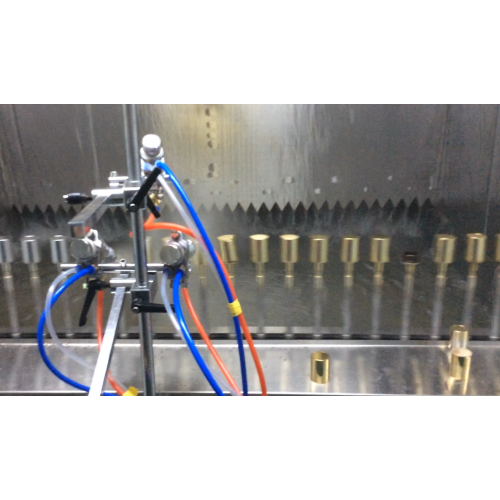

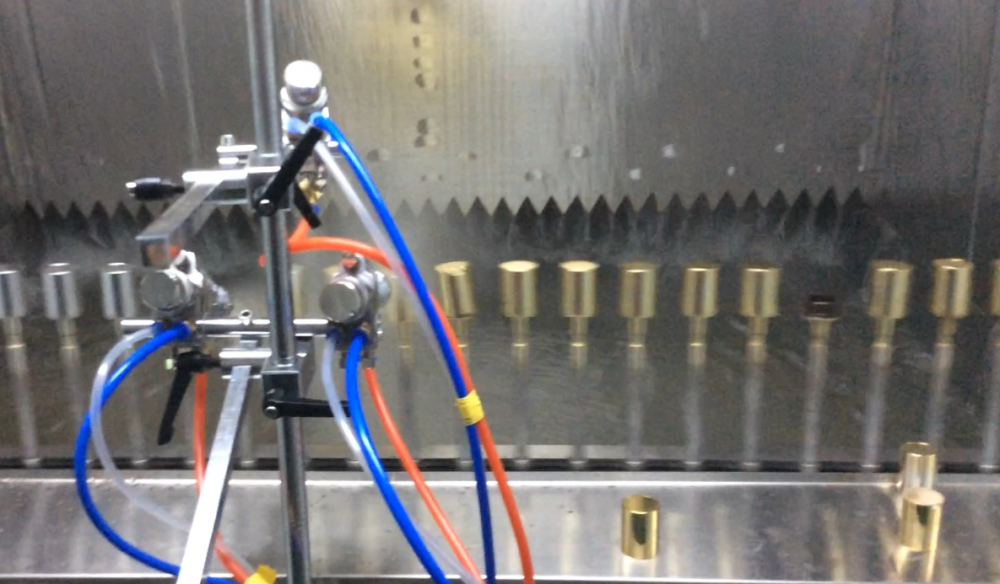

2 automatic spraying technology, equipped with Japan IWATA automatic spray gun, customers can also choose ABB automatic spraying robot.

3 curtain-type spray booth design, paint mist recovery processing system, greatly reducing the spread of pollution paint pollution.

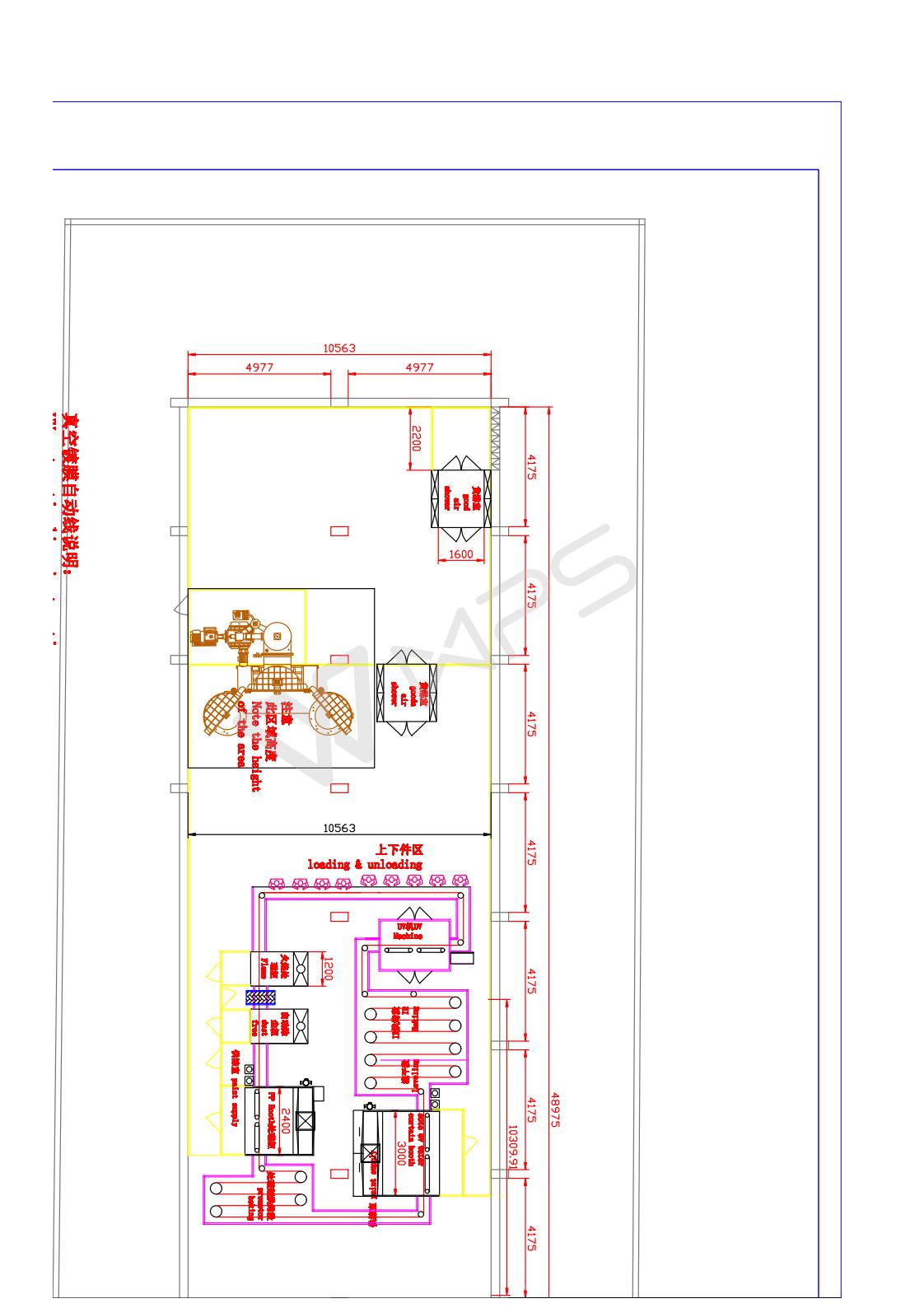

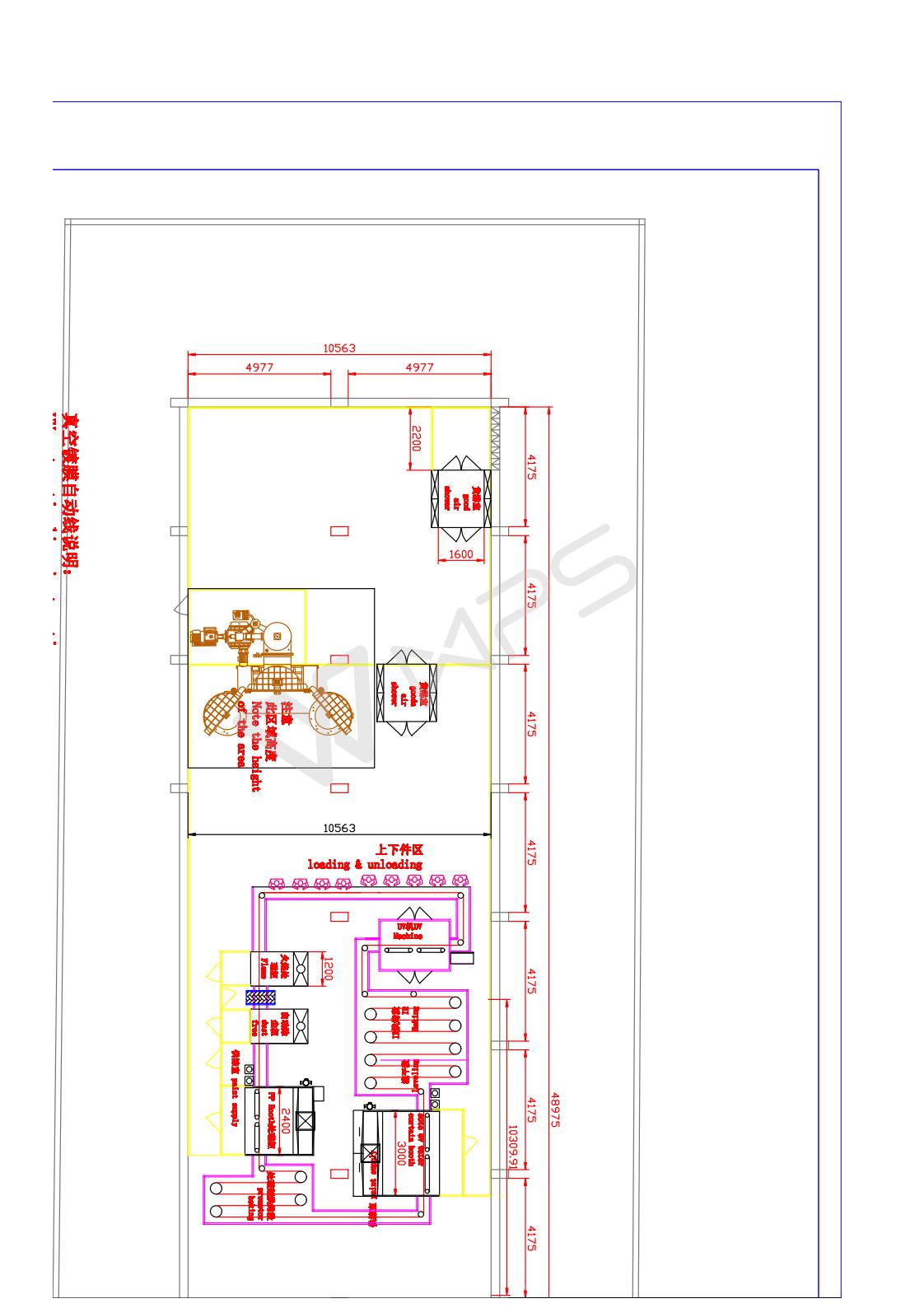

4 automatic chain design, flexible body planning, installation planning

5 new design of the man-machine interface, PLC automation control system, easy operation, all at your fingertips.

6 reasonable infrared heating arrangement, full-angle UV curing layout, rapid completion of the dead-end preheat curing process

Technical configuration:

Line length: length can be customized, single spray single grilled, double spray double grilled, the general automatic line length of 50 meters, 90 meters, 120 meters, 200 meters and so on.

Rotor chain: variable frequency adjustment drive chain

Electrostatic dust: independent automatic electrostatic precipitator room, equipped with 6 electrostatic dust guns

Flame treatment: Multi-flame gun, improve the coating adhesion of specific products

Automatic spraying: Independent automatic spray booth, equipped with multi-branch SWATA Japan Iwata automatic spray gun, optional automatic ABB spraying robot

Infrared leveling: accurate calculation of the infrared baking length, the use of multi-branch newly developed infrared heating system, adjustable temperature control

UV curing: Equipped with high-power UV lamp, full-angle UV lighting system

Air purification: The use of high efficiency filters to improve air purification rate and cleanliness

HENGYIJIA-UV series of automatic coating lines have advanced complete spraying system, mainly for the vacuum coating products to provide automatic humanized primer, topcoat spraying.

It can be widely applied to the UV spraying of plastic, metal, glass, ceramic and other materials. UV spraying technology has excellent surface forming ability, giving products high-density adhesion and uniform coating.

A complete line coating system, flame treatment room, electrostatic precipitator room, UV automatic spray booth, infrared preheat leveling, UV light curing, cooling air chamber.

2 automatic spraying technology, equipped with Japan IWATA automatic spray gun, customers can also choose ABB automatic spraying robot.

3 curtain-type spray booth design, paint mist recovery processing system, greatly reducing the spread of pollution paint pollution.

4 automatic chain design, flexible body planning, installation planning

5 new design of the man-machine interface, PLC automation control system, easy operation, all at your fingertips.

6 reasonable infrared heating arrangement, full-angle UV curing layout, rapid completion of the dead-end preheat curing process

Technical configuration:

Line length: length can be customized, single spray single grilled, double spray double grilled, the general automatic line length of 50 meters, 90 meters, 120 meters, 200 meters and so on.

Rotor chain: variable frequency adjustment drive chain

Electrostatic dust: independent automatic electrostatic precipitator room, equipped with 6 electrostatic dust guns

Flame treatment: Multi-flame gun, improve the coating adhesion of specific products

Automatic spraying: Independent automatic spray booth, equipped with multi-branch SWATA Japan Iwata automatic spray gun, optional automatic ABB spraying robot

Infrared leveling: accurate calculation of the infrared baking length, the use of multi-branch newly developed infrared heating system, adjustable temperature control

UV curing: Equipped with high-power UV lamp, full-angle UV lighting system

Air purification: The use of high efficiency filters to improve air purification rate and cleanliness

Electrical Control: PLC automatic control system, adjustable process parameters.

Related Keywords

Related Keywords