spray coating line for phone covers

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 25 |

| Supply Ability: | 6 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

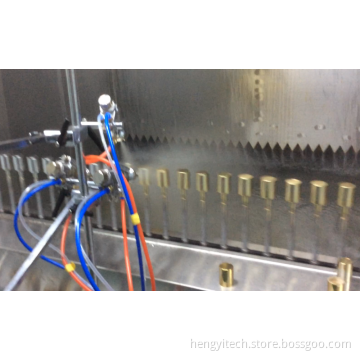

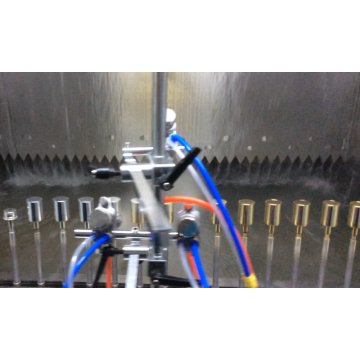

Full automatic spray coating line for cell phone covers

Our company provides spray coating line for phone covers. Spraying of mobile phone cases is divided into one spray one baking, two spray two baking, three spray three baking automatic production lines and a special automatic dust-free electrostatic spraying production line for spraying the surface of the mobile phone case. The rate can reach 95%, good cleaning effect, high surface hardness,

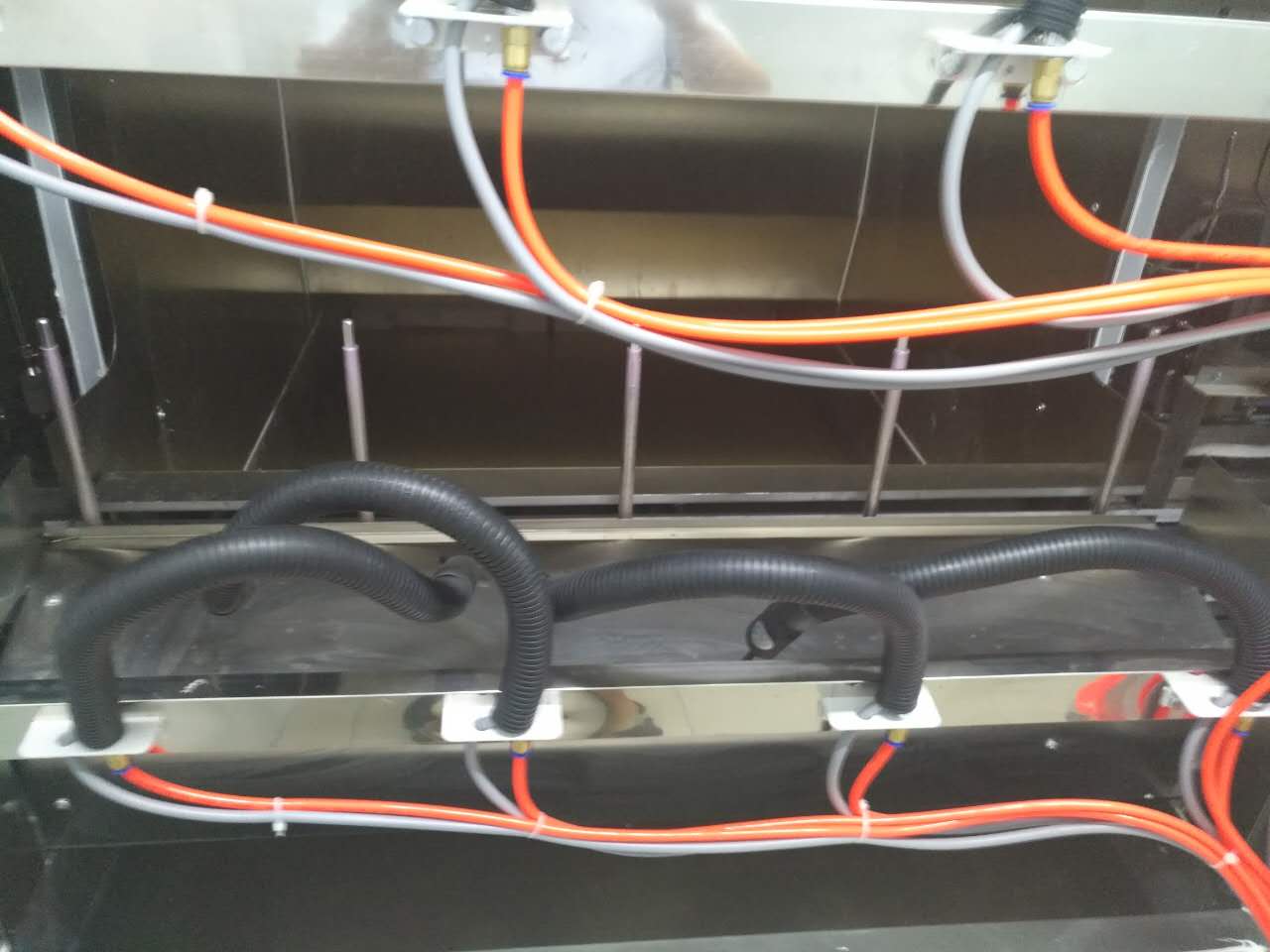

Principle characteristics:loading- dedusting- spraying - levelling - drying (or UV curing) - unloading, integrated automation dustless coating equipment. Adopts the man-machine interface input, PLC programming control, simple operation and reliable. The most prominent characteristic is high output (per hour can spray keyboard 1200-1500 sets), and the percent of pass is high (spraying qualified rate above 96%). Coating thickness uniformity and stability. It's the prefered device for cell phone casing, keyboard manufacturing mass production.

I, suitable products:

Mobile phone, camera, MP3, speaker box, toys, cosmetics boxes, keyboard, mouse. DVD, etc.

II, the spraying process:

loading - manual work electrostatic dust removal – automatic electrostatic dust removal – automatic spraying - standing baking cooling - UV curing - unloading.

III, appearance size: L 16 m x W 6 m x H 3 m. (planning is according to the customer shop and product situation)

IV, process data:

a. The chain conveyor speed: 0-8 m/min.

b. The workpiece rotation speed: 10-200 r/min.

c. The workpiece diameter size: 300 mm * 400 mm in height.

d. Production: 400-8000 a/h (depending on the workpiece size change).

e. Gun number: gun quantity: 2-12 pcs (depending on the product)

f. Spraying method: workpiece rotation (forward, reverse) in cooperation with each Angle gun sequence spraying.

g. Spray booth: three surface water washing, Vortex flow, negative pressure exhaust.

h. air supplement:

Our company provides spray coating line for phone covers. Spraying of mobile phone cases is divided into one spray one baking, two spray two baking, three spray three baking automatic production lines and a special automatic dust-free electrostatic spraying production line for spraying the surface of the mobile phone case. The rate can reach 95%, good cleaning effect, high surface hardness,

Principle characteristics:loading- dedusting- spraying - levelling - drying (or UV curing) - unloading, integrated automation dustless coating equipment. Adopts the man-machine interface input, PLC programming control, simple operation and reliable. The most prominent characteristic is high output (per hour can spray keyboard 1200-1500 sets), and the percent of pass is high (spraying qualified rate above 96%). Coating thickness uniformity and stability. It's the prefered device for cell phone casing, keyboard manufacturing mass production.

I, suitable products:

Mobile phone, camera, MP3, speaker box, toys, cosmetics boxes, keyboard, mouse. DVD, etc.

II, the spraying process:

loading - manual work electrostatic dust removal – automatic electrostatic dust removal – automatic spraying - standing baking cooling - UV curing - unloading.

III, appearance size: L 16 m x W 6 m x H 3 m. (planning is according to the customer shop and product situation)

IV, process data:

a. The chain conveyor speed: 0-8 m/min.

b. The workpiece rotation speed: 10-200 r/min.

c. The workpiece diameter size: 300 mm * 400 mm in height.

d. Production: 400-8000 a/h (depending on the workpiece size change).

e. Gun number: gun quantity: 2-12 pcs (depending on the product)

f. Spraying method: workpiece rotation (forward, reverse) in cooperation with each Angle gun sequence spraying.

g. Spray booth: three surface water washing, Vortex flow, negative pressure exhaust.

h. air supplement:

The clean level requirements planning different levels of the supply air filter system. Clean positive pressure fresh air supply, the initial effect, in effect, in effect, the four filter with vortex type spray, positive pressure spraying. Chain conveyor to choi steel rock wool oven, far infrared heating tube baking, import temperature control section control, can add UV curing oven, clean room workshop class to static class dynamic level.

Related Keywords

Related Keywords