Plastic Fixed-gun UV Spray Painting Line

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 38 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO |

| Transportation: | Ocean |

| Port: | Shenzhen |

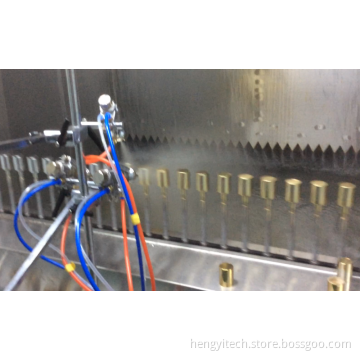

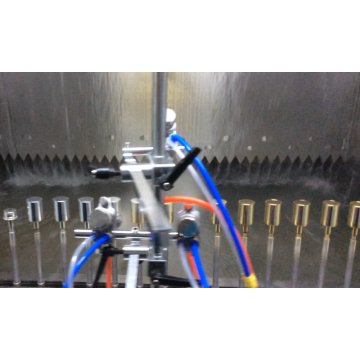

Plastic Fixed-gun UV Spray Painting Line System

Product Description

DETAILED DESCRIPTION

The machine use Vacuum metallizing technology match with Painting line to get all kinds of color metallic finishing on Products.We can do Turnkey Project for customers including Vacuum PVD coating, UV Automatic Painting line.

Technology

The equipment adopts the resistance heating in the vacuum chamber, to melt and vaporize the metal wire (aluminum wire) cling to the resistance wire. The vaporized metal molecule deposit on the substrates, to gain the smooth film as well as high reflectivity. Thus the surface of the items can be decorated and beautified.

Thermal Resistance Evaporation Coating Technology: Thermal vacuum deposition is one method for fabricating thin films under a high vacuum environment also addressed as "thermal evaporation method". With this method, an electron beam (e-beam) or resistive heating is usually used to evaporate the desired material inside the vacuum coating chamber, which then adheres to a substrate placed above it. This method can classified as a form of PVD, which stands for physical vapor deposition, and is suitable for fabricating high-quality thin films with thicknesses on the order of nanometers on glass, plastic, films, metals, and almost any other kind of material.

Features

Characteristic: reasonable structure, even film, good-quality film forming, quick pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability.

Application

Applied industry: Widely used in automotive, audio and varinous small appliances, computers, clocks and watches, toys cell phones reflective Cup, cosmetics toys tableware sanitary shoe heel, ABS, PS, PP, PC, PVC, PET, nylon,metal, Boli, glass, ceramics, TPU, etc.

Electroplating effects: general electroplating-face, dumb-(semi-mute, all dumb), the electroplating process wrinkles, wiredrawing,raindrop ect.

Coating color: gold, silver, red, blue, green, purple,rainbow color ect.

Related Keywords