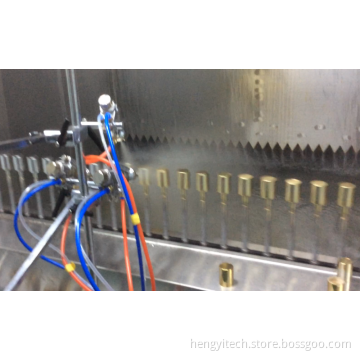

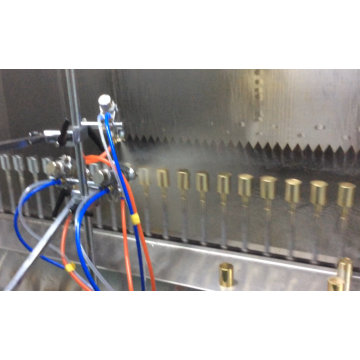

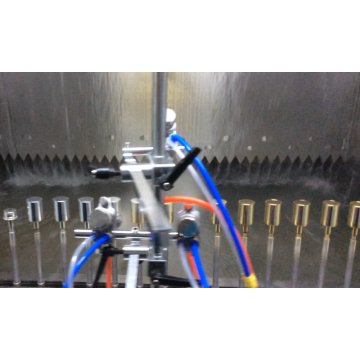

Plastic automatic spraying equipment

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 38 |

| Supply Ability: | 8 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

Process information:

Conveying speed: V = 0-8 m / min frequency control.

2. Workpiece rotation: V = 10-200R / min adjustable frequency.

3. Production: 500-5000 pieces / h (depending on the size of the workpiece and pendant method).

4. Number of guns: 6-8 guns per spray (depending on the spray can be increased or decreased).

5. Painting method: the workpiece forward and reverse rotation with the angle of the fixed spray gun spray.

6 spray room: million design, washed clean room, negative pressure exhaust.

7. For the wind: according to the level of demand for different levels of gas supply filtration system.

8. Baking: far infrared heating, temperature: Tmax = 100 ℃ ± 3 ℃ adjustable.

9. Control: the use of programmable PLC control, incoming automatic detection, spraying.

Process: (2 coated with 2 roasted as an example)

On → manual dust removal → automatic electrostatic precipitator → automatic spray primer → leveling → baking → automatic electrostatic dust removal → automatic spray paint → leveling → baking → UV curing → the next.

product manual:

Workpiece rotation automatic spraying machine (a coated a roast, two Tu two roasted, three Tu three roasted, plus UV curing)

First, the applicable products:

Mobile phones, cameras, MP3, speakers, toys, cosmetics box, keyboard, mouse, camera, DVD and so on.

Second, the spraying process:

1 on the material -2 artificial electrostatic dust-3 automatic electrostatic dust-4 automatic

Spray-5 Empty Bake Cool-6 UV Cure-7 Recycling

Plus a coating of a roast 3,4,5 process need to add a group of equipment).

Third, the appearance of size: L16 m x W6 m x H3 m. (According to the customer workshop and product planning)

Fourth, the process information:

1. Chain delivery speed: 0-8 m / min.

2. workpiece rotation speed: 10-200 r / min.

3. Workpiece size: diameter 300 mm * height 400 mm.

4. Production: 400-8000 pieces / h (according to the size of the workpiece changes).

5. Number of guns: number of guns: 2-12 (depending on the product)

6. Spray method:

Workpiece rotation (forward, reverse) with the angle of the spray gun spray.

7. Sprinkler: three sides washed, vortex flow, negative pressure exhaust.

8. Breath:

According to the level of dust-level requirements of different levels of gas supply filtration system. Clean positive pressure fresh air supply, the initial effect, in effect, the effect of four-tier university filter with scroll-type spray, positive pressure spray. Chain conveyor to the color steel plate Yanmian oven, far infrared heating pipe baking, import temperature control sub-control, can add UV curing furnace, dust room workshop million to static million dynamic one hundred thousand.

9. Oven:

Color steel appearance, far red fever, rock wool insulation, SCR sub-control

With UV curing furnace construction.

10. Operation:

The man-machine interface adopts programmable PLC programmable touch screen, automatic sensor interface control, infrared sensor, incoming self-test, automatic spraying.

Five, features:

Conveying speed: V = 0-8 m / min frequency control.

2. Workpiece rotation: V = 10-200R / min adjustable frequency.

3. Production: 500-5000 pieces / h (depending on the size of the workpiece and pendant method).

4. Number of guns: 6-8 guns per spray (depending on the spray can be increased or decreased).

5. Painting method: the workpiece forward and reverse rotation with the angle of the fixed spray gun spray.

6 spray room: million design, washed clean room, negative pressure exhaust.

7. For the wind: according to the level of demand for different levels of gas supply filtration system.

8. Baking: far infrared heating, temperature: Tmax = 100 ℃ ± 3 ℃ adjustable.

9. Control: the use of programmable PLC control, incoming automatic detection, spraying.

Process: (2 coated with 2 roasted as an example)

On → manual dust removal → automatic electrostatic precipitator → automatic spray primer → leveling → baking → automatic electrostatic dust removal → automatic spray paint → leveling → baking → UV curing → the next.

product manual:

Workpiece rotation automatic spraying machine (a coated a roast, two Tu two roasted, three Tu three roasted, plus UV curing)

First, the applicable products:

Mobile phones, cameras, MP3, speakers, toys, cosmetics box, keyboard, mouse, camera, DVD and so on.

Second, the spraying process:

1 on the material -2 artificial electrostatic dust-3 automatic electrostatic dust-4 automatic

Spray-5 Empty Bake Cool-6 UV Cure-7 Recycling

Plus a coating of a roast 3,4,5 process need to add a group of equipment).

Third, the appearance of size: L16 m x W6 m x H3 m. (According to the customer workshop and product planning)

Fourth, the process information:

1. Chain delivery speed: 0-8 m / min.

2. workpiece rotation speed: 10-200 r / min.

3. Workpiece size: diameter 300 mm * height 400 mm.

4. Production: 400-8000 pieces / h (according to the size of the workpiece changes).

5. Number of guns: number of guns: 2-12 (depending on the product)

6. Spray method:

Workpiece rotation (forward, reverse) with the angle of the spray gun spray.

7. Sprinkler: three sides washed, vortex flow, negative pressure exhaust.

8. Breath:

According to the level of dust-level requirements of different levels of gas supply filtration system. Clean positive pressure fresh air supply, the initial effect, in effect, the effect of four-tier university filter with scroll-type spray, positive pressure spray. Chain conveyor to the color steel plate Yanmian oven, far infrared heating pipe baking, import temperature control sub-control, can add UV curing furnace, dust room workshop million to static million dynamic one hundred thousand.

9. Oven:

Color steel appearance, far red fever, rock wool insulation, SCR sub-control

With UV curing furnace construction.

10. Operation:

The man-machine interface adopts programmable PLC programmable touch screen, automatic sensor interface control, infrared sensor, incoming self-test, automatic spraying.

Five, features:

Spraying speed, spraying and, according to the workpiece changes, automatically adjust the gun, high and low, before and after the angle position can be used with the board version of the simulation program to reduce the amount of time to stop shooting guns, gun conditions, digital memory, reduce dependence on the master , Production management easy.

Related Keywords

Related Keywords