Plastic clean coating line

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 37 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

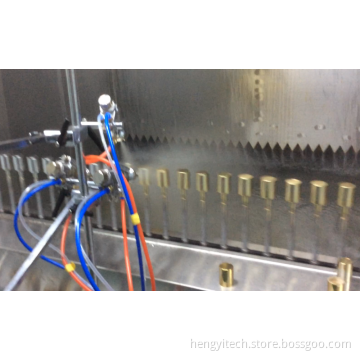

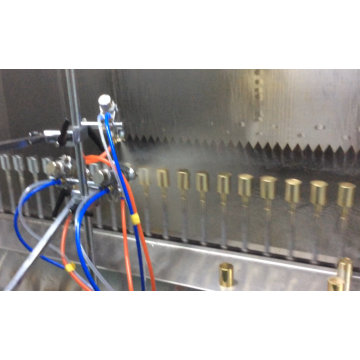

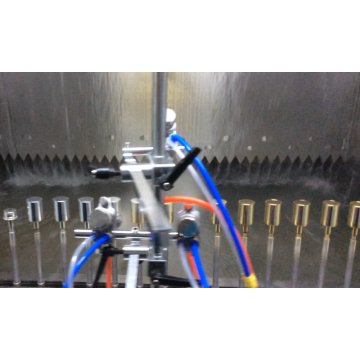

Plastic dust-free coating line applications

Dust-free coating is made of steel sandwich panels are fully enclosed production workshop, can effectively control the bad air pollution of the product, reduce the spray room dust and product non-performing rate. Clean coating technology to improve customer demand for quality, won the trust of customers, enhance the company's products in the market competitiveness.

Plastic clean coating line composition

1). Plane transport system; 2). Electrostatic dust removal system;

3). Manual spraying system; 4) Drying curing system;

5). Purification workshop series; 6). Fresh air system;

7). Exhaust gas treatment system; 8). Centralized electrical control system;

Box air conditioning air purifier unit purification level: curtain + early effect + in effect + efficiency is divided into the intake section, the new wind at the beginning of the paragraph, the fan section, in the effective filter section, efficient section of the wind.

The air supply unit is box type, galvanized steel plate and steel structure. Use the duct to clean the fresh air into the spray chamber at the top of the pressure steady flow chamber, and then by the end (ceiling) the third high efficiency filter into the purification operation area. The use of frequency converter to adjust the amount of air to keep the operating area for the micro-positive pressure to prevent the outside world unclean air into the purification operation area to ensure that the product surface quality.

Asahi coating for the design of a company in Shanghai closed, fresh air purification air supply, spraying, drying, cooling coating lines.

(Such as computers, home appliances, cameras, mobile phones, toys, LCD panel shell). It is widely used in the fields of plastic, metal, leather, wood, glass, magnesium alloy and other products. The following are the same as the "

◆ plastic dust-free coating line features:

1. The use of domestic original mandatory rotation of the chain. The design uses a sprocket to drive the chain.

2. Operation is smooth, uniform, do not turn away; can greatly improve the product yield, reduce defective, waste.

3. Speed 0-15 m / min adjustable. According to the characteristics of the spray paint to adjust the chain speed, improve productivity.

4. Machine spray cabinet made of stainless steel, rust and easy to clean oil.

5. The electrical system mainly uses programmable logic (PLC) controller and man-machine interface (touch screen) to control the import more humane.

6. Reasonable and efficient process configuration, not only to optimize the performance of equipment, but also take into account environmental protection.

Dust-free coating is made of steel sandwich panels are fully enclosed production workshop, can effectively control the bad air pollution of the product, reduce the spray room dust and product non-performing rate. Clean coating technology to improve customer demand for quality, won the trust of customers, enhance the company's products in the market competitiveness.

Plastic clean coating line composition

1). Plane transport system; 2). Electrostatic dust removal system;

3). Manual spraying system; 4) Drying curing system;

5). Purification workshop series; 6). Fresh air system;

7). Exhaust gas treatment system; 8). Centralized electrical control system;

Box air conditioning air purifier unit purification level: curtain + early effect + in effect + efficiency is divided into the intake section, the new wind at the beginning of the paragraph, the fan section, in the effective filter section, efficient section of the wind.

The air supply unit is box type, galvanized steel plate and steel structure. Use the duct to clean the fresh air into the spray chamber at the top of the pressure steady flow chamber, and then by the end (ceiling) the third high efficiency filter into the purification operation area. The use of frequency converter to adjust the amount of air to keep the operating area for the micro-positive pressure to prevent the outside world unclean air into the purification operation area to ensure that the product surface quality.

Asahi coating for the design of a company in Shanghai closed, fresh air purification air supply, spraying, drying, cooling coating lines.

(Such as computers, home appliances, cameras, mobile phones, toys, LCD panel shell). It is widely used in the fields of plastic, metal, leather, wood, glass, magnesium alloy and other products. The following are the same as the "

◆ plastic dust-free coating line features:

1. The use of domestic original mandatory rotation of the chain. The design uses a sprocket to drive the chain.

2. Operation is smooth, uniform, do not turn away; can greatly improve the product yield, reduce defective, waste.

3. Speed 0-15 m / min adjustable. According to the characteristics of the spray paint to adjust the chain speed, improve productivity.

4. Machine spray cabinet made of stainless steel, rust and easy to clean oil.

5. The electrical system mainly uses programmable logic (PLC) controller and man-machine interface (touch screen) to control the import more humane.

6. Reasonable and efficient process configuration, not only to optimize the performance of equipment, but also take into account environmental protection.

7. Adapt: plastic, cosmetic packaging containers, electronics, electrical appliances, hardware and other surface dust-free automatic spraying, especially in the vacuum coating industry has been widely used.

Related Keywords

Related Keywords