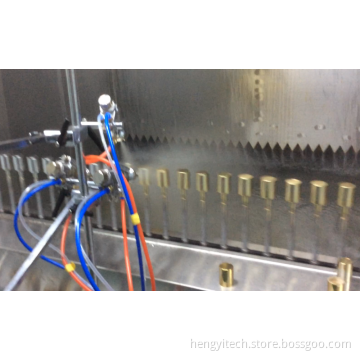

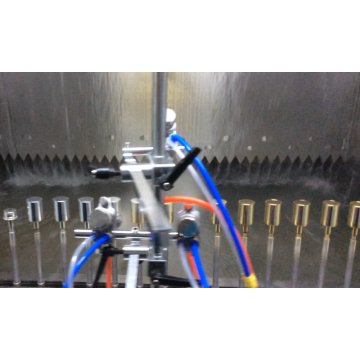

automated spray for pen machine

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shekou, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 40 |

| Supply Ability: | 40 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shekou,Yantian |

Applicable scope: one of the low temperature models, button contact interface, suitable for low temperature curing requirements of the product applications, such as: plastic, cosmetic packaging containers, electronics, electrical appliances, hardware and other surface dust free automatic spraying, especially in the vacuum coating industry is widely Application of watch industry applications, plastic and metal case can be applied.

Technical specifications and requirements

1, design conditions

Name: plastic shell

Material: Plastic (ABS + PC)

Workpiece size: H100 Φ300mm

Design yield: 3000 pieces / Hr (subject to conventional workpiece)

Chain speed: 3-12m / min (continuous adjustable)

Delivery: plane automatic delivery (A line of about 140 meters, B line length of about 75 meters)

Fixture spacing: 38.1mm, bolt spacing 38.1mm

Site area: L46 meters * W27 meters * H3.9 meters

Spray method: fixed gun spray

Heating method: electric heating

Curing time: pre-roasted 7 meters, baked primer 35 meters, UV homogenization of 25 meters

Purification level: Painting area (spray room, drying Road, paint room,) for 10,000, other areas of 100,000

2, the process

On the line → manual dust → automatic dust removal → preheat → spray primer (fixed 12 guns) → leveling (4min) → IR curing (80 ℃ 35 meters) → 5 meters cooling → finish (fixed 12 guns) → IR homogenization (60 ℃ * 25 meters) → UV light curing (8-5KW) → cooling → lower → coating.

3, the specific process overview

The entire coating operation area (including the upper and lower parts area) for the whole closed decoration, the staff entrance with the air shower and the outside cut off, the area by the strong supply of air supply to the purified fresh air to ensure its air cleanliness Not less than 100000 level. The cart is loaded with the workpiece into the "out of the box area", the workpiece removed, the interior with assembly table, manual assembly of the workpiece and then manually in addition to electrostatic dust, through the plane conveyor into the "spray line Room ", and then with the conveyor chain on the rule of the plug. (Please note that the program used in the rule of a special design, processing, its flexible rotation, easy to plug, is the industry's leading technology). On the line of the workpiece into the automatic dust removal device before dehumidification drying section, the equipment is our company through continuous summary and continuous communication with the user and specially designed to reduce the workpiece surface humidity, to ensure the quality of spraying. And then the workpiece through the automatic addition to electrostatic precipitator, once again to eliminate the residual static charge on the workpiece and dust. In order to make every part of the workpiece can be completely dust, the conveyor chain in the station with rotation device, the workpiece automatically in addition to static dust is carried out in the rotation, dust removal effect is good. We chose the electrostatic precipitator for the German product Styker card, is a well-known brands. Pay attention to the removal of the workpiece is a significant feature of this program.

After two dust removal of the workpiece directly into the spray room. Spray room is the production line *** important work area, by the air supply device sent by the fresh air 99.995% high efficiency filter again after the fine filter into the spray room; cleanliness within 10,000 levels, the exhaust is from The exhaust fan of the sprayer is discharged to the roof. Before the exhaust gas is discharged, more than 80% of the paint mist contained therein has been trapped by the curtain and vortex double treatment of the sprayer, and generally does not exceed the emission limit. The program designed spray indoor air flow rate of 0.6 to 1 m / s, to ensure safe, non-toxic, and no vortex air and secondary pollution.

Related Keywords