UV Coating Line for Bottle Vacuum Metallization

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 45 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 36 |

| Supply Ability: | 7 |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO,CE |

| Transportation: | Ocean |

| Port: | Shenzhen |

Product Description

Product Description

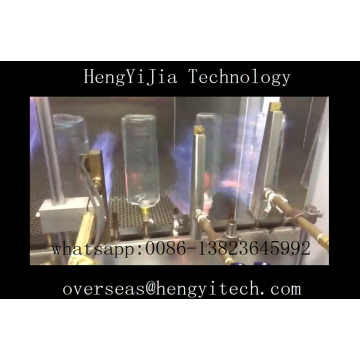

Automatic UV Varnish Coating Line for glass Bottle Vacuum Metallization is configured for full automatic spraying on conveyor systems. Painting line is compatible with different coatings to deal with different painting requirements. UV line is widely used in various industries like food, furnitures, plastic and woodware etc.

Specifications

Compatible with different products

Fast painting and curing

Less maintenance required

Long life span

UV coating line workflow(for reference): Loading -> manual de-dust -> base coat spray -> flash off -> curing -> top coat spray -> IR leveling -> curing -> cooling -> unloading

Detailed working process

Base painting: Load products on line-electrostatic cleaning-base painting-IR leveling-UV curing-cooling-off line

Vacuum coating: load products in evaporation vacuum coating machine-metallizing-unload products

Top painting: load products on UV line-electrostatic cleaning-top painting-IR leveling preheating-UV curing-cooling-unload products

Welcome to contact us today for custom designs and visit our company for installation view. We'll be more than happy to provide you the best quotation!

uv coating line is popularly installed in dust free room for easy and high quality production. Temperature and humidity control is crucial for stable & high quality production, thus AHU air conditioning system is always applied for car parts uv painting system such as lamp cover uv painting, mirror cover uv painting etc.

Specifications

Compatible with different products

Fast painting and curing

Less maintenance required

Long life span

UV coating line workflow(for reference): Loading -> manual de-dust -> base coat spray -> flash off -> curing -> top coat spray -> IR leveling -> curing -> cooling -> unloading

Detailed working process

Base painting: Load products on line-electrostatic cleaning-base painting-IR leveling-UV curing-cooling-off line

Vacuum coating: load products in evaporation vacuum coating machine-metallizing-unload products

Top painting: load products on UV line-electrostatic cleaning-top painting-IR leveling preheating-UV curing-cooling-unload products

Welcome to contact us today for custom designs and visit our company for installation view. We'll be more than happy to provide you the best quotation!

uv coating line is popularly installed in dust free room for easy and high quality production. Temperature and humidity control is crucial for stable & high quality production, thus AHU air conditioning system is always applied for car parts uv painting system such as lamp cover uv painting, mirror cover uv painting etc.

Related Keywords

Related Keywords