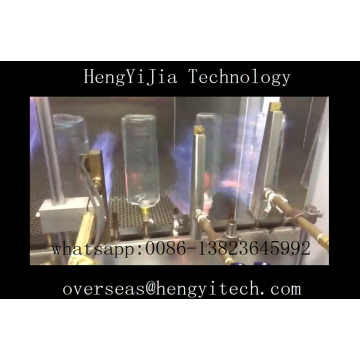

automatic painting system for glass products

- Payment Type:

- T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200000 |

| Supply Ability: | 3000sets per year |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001 |

| Transportation: | Ocean |

Glass bottle spray painting operation skills :

1, the air pressure is best controlled at 0.3-0.4 MPa (3-4 kg force / square centimeter). Pressure is too small, poor paint spray, the surface will form pitting: pressure is too large and easy to hang, and the mist is too large, both a waste of material

2, the nozzle and the surface of the general spacing of 200-300 mm is appropriate. Too close to easy flow hanging; too far paint mist is not uniform, prone to pitting, and the nozzle from the surface of the far paint mist in the way of flying waste. The specific size of the interval, should be based on the types of glass paint, viscosity and pressure to adjust the size of the appropriate. When the air pressure, the distance can be a little bit, the pressure can be close to a little hour; the so-called far point is a little far between the 10 mm -50 mm range of adjustment, the pressure is too small, If this range is exceeded, it is difficult to obtain a desired paint film.

3, the gun can be used for up and down, left and right movement, preferably 10-12 m / min speed of uniform action, the nozzle should be straight to the surface coating, minimize oblique spraying. When sprayed to the surface at both ends of the gun, the gun button to quickly trigger the pine look, so that paint mist, due to the two ends of the surface, often to accept more than two spray, is the most likely to cause sagging place.

4, when spraying under a pressure to suppress a 1/3 or 1/4, so as not to leak leakage phenomenon. In the quick-drying paint spray, the need for a spray in accordance with the order. Fill spray effect is not satisfactory. In this case,

5, Spraying the workshop is recommended in a sealed environment. Especially in the UV spray production conditions need to do dust-free workshop. Spray the thermosetting paint when you can not do dust-free workshop.

Automatic painting system /automatic production line for cosmetic bottles, wine bottles, perfume bottles, and other glass bottles.

Glass bottle spray painting operation skills :

1, the air pressure is best controlled at 0.3-0.4 MPa (3-4 kg force / square centimeter). Pressure is too small, poor paint spray, the surface will form pitting: pressure is too large and easy to hang, and the mist is too large, both a waste of material

2, the nozzle and the surface of the general spacing of 200-300 mm is appropriate. Too close to easy flow hanging; too far paint mist is not uniform, prone to pitting, and the nozzle from the surface of the far paint mist in the way of flying waste. The specific size of the interval, should be based on the types of glass paint, viscosity and pressure to adjust the size of the appropriate. When the air pressure, the distance can be a little bit, the pressure can be close to a little hour; the so-called far point is a little far between the 10 mm -50 mm range of adjustment, the pressure is too small, If this range is exceeded, it is difficult to obtain a desired paint film.

3, the gun can be used for up and down, left and right movement, preferably 10-12 m / min speed of uniform action, the nozzle should be straight to the surface coating, minimize oblique spraying. When sprayed to the surface at both ends of the gun, the gun button to quickly trigger the pine look, so that paint mist, due to the two ends of the surface, often to accept more than two spray, is the most likely to cause sagging place.

4, when spraying under a pressure to suppress a 1/3 or 1/4, so as not to leak leakage phenomenon. In the quick-drying paint spray, the need for a spray in accordance with the order. Fill spray effect is not satisfactory. In this case,

5, Spraying the workshop is recommended in a sealed environment. Especially in the UV spray production conditions need to do dust-free workshop. Spray the thermosetting paint when you can not do dust-free workshop.

Automatic painting system /automatic production line for cosmetic bottles, wine bottles, perfume bottles, and other glass bottles.

3 steps for the automatic painting system procedure.

Step 1: Painting for base coat.

Step 2: Vacuum coating/metallizing.

Step 3: Painting for top coat.

Example plan for automatic spray painting equipment/auto spray painting line for glass bottle.

Designed condition required:

Factory space

spray painting equipment/line specification :90 degree tunning guiding wheel Φ240mm, back turning 1800 degree Φ 300mm wheel

Line speed : 1-25M/min, frequency conversion and adjustable

Heat sourcing: heating tubes

Curing oven temperature: 0-100℃ can be adjustable.

Power: AC380V 50HZ 3 phase

Lighting:AC220V 50HZ single phase

Power control:AC220V (transforming in the power box)

Compressor supply: :0.6±0.05MPa

Whater preasure :0.1MPa(1.0kg/cm2 above)

Spindle :44.45㎜

23pcs spindle per 1 meter

Line length:56m

equipment total power : 80KW

Auto spray painting equipment production process:

Labor loading productions→electrostatic dust free---flame treatment---UV base coat,top coat spray booth→heating leveling→light curing---unloading for vacuum metallizing.

Electrostatic Dust Free Booth

Dimension: W1200mm*D1700mm*H1800mm

Flame treatment booth

Booth Dimension : W1200mm*D1700mm*H1800mm

UV base coat top coat spray booth

Water curtain booth :

Dimension :W3000mm*D2400mm*H2400mm

Spray gun systems:

Spray gun:WA-101 model(1.3 nozzle)

Rotation sstem

Solenoid valune spray gun control

Rotation type: belt rotation , front and back rotation function,crocking resistance , frequency conversion adjustable.

IR lamps for heating

oven hight :800㎜

Temperature adjustable : 0-100℃

Chainlink passway:600㎜

Electricity control system

Brand component.

Equipment Material:

stainless steel .

The equipment without including air supply ,exhaust pipes, deducting compressor etc.

Payment terms: 35% TT deposit, 65% TT balance before shipment.

Installation onsite support: 2 engineers for guiiding.

Coating effect on our automatic painting system.

Related Keywords