automatic spray line for cosmetics containers

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 30000per hour |

| Supply Ability: | 150 Lines per year |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | CE MSDS |

| Transportation: | Ocean |

Heng Yi Jia manufacturing automatic spray line for cosmetics containers like Lotion, cream, perfume glass containers. one time invest on automatic spray line, long time returms for your beautiful cosmetic packages. we offer a full set of solution for your package painting, special design automatic spray line with considering your product material, maximum and minimum size, production capacities per hour or per day to work out a perfect line match with your factory site, space, and also convenient to saving electricity during long time production, save labour and rising production efficiency and quality rate.

We exported to USA, India, Gemary, Egypt, Spain, UK, Sudan, Pakistan, Indonisia, Singapore, Malaysia etc. Happy cooperation with all the customer in quality product, onsite installation guiding, technology opeation training and skills share in coating field.

Own design & manufacture & selling Auto painting equipment for glass bottle, like brand wine bottle, cosmetics packages ,perfume bottle etc. fruitful experience in manufacturing and installation for fully automatic spray painting line in glass product field. we get solution for your full technology support in operating the line and skills for making better quality product coating.

Example plan for automatic spray painting equipment/auto spray painting line for glass bottle.

Designed condition required:

Factory space

spray painting equipment/line specification :90 degree tunning guiding wheel Φ240mm, back turning 1800 degree Φ 300mm wheel

Line speed : 1-25M/min, frequency conversion and adjustable

Heat sourcing: heating tubes

Curing oven temperature: 0-100℃ can be adjustable.

Power: AC380V 50HZ 3 phase

Lighting:AC220V 50HZ single phase

Power control:AC220V (transforming in the power box)

Compressor supply: :0.6±0.05MPa

Whater preasure :0.1MPa(1.0kg/cm2 above)

Spindle :44.45㎜

23pcs spindle per 1 meter

Line length:56m

equipment total power : 80KW

Auto spray painting equipment production process:

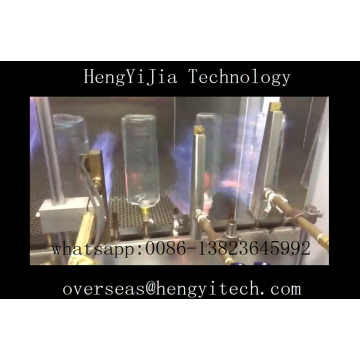

Labor loading productions→electrostatic dust free---flame treatment---UV base coat,top coat spray booth→heating leveling→light curing---unloading for vacuum metallizing.

Electrostatic Dust Free Booth

Dimension: W1200mm*D1700mm*H1800mm

Flame treatment booth

Booth Dimension : W1200mm*D1700mm*H1800mm

UV base coat top coat spray booth

Water curtain booth :

Dimension :W3000mm*D2400mm*H2400mm

Spray gun systems:

Spray gun:WA-101 model(1.3 nozzle)

Rotation sstem

Solenoid valune spray gun control

Rotation type: belt rotation , front and back rotation function,crocking resistance , frequency conversion adjustable.

Heating leveling oven

IR lamps for heating

oven hight :800㎜

Temperature adjustable : 0-100℃

Chainlink passway:600㎜

Electricity control system

Brand component.

Equipment Material:

stainless steel .

The equipment without including air supply ,exhaust pipes, deducting compressor etc.

Payment terms: 35% TT deposit, 65% TT balance before shipment.

Installation onsite support: 2 engineers for guiiding.

Related Keywords