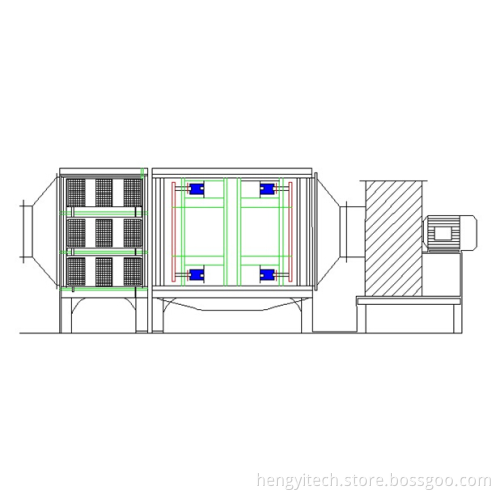

Spray painting exhaust system

-

$4.90≥1 Piece/Pieces

- Payment Type:

- T/T, L/C, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air, s

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 200000pcs/year |

| Supply Ability: | 100000 sets/year |

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,s |

| Port: | SHENZHEN |

Product Description

Product Description

Spray painting exhaust system

VOCs Emissions:

Benzene, toluene, xylene, styrene, butyl acetate, trimethy lolpropane triacrylate,

2-heptanone, hydroxycyclohexyl phenyl ketone, dimethyl polymer, triazine and ethylene oxide, hydroxyethyl methacrylate, pentaerythritol tetraacrylate

Several basic elements of governance options:

Depending on the composition of the exhaust gas (whether it contains moisture, solids, oily, and ease of handling), concentration (high, low), emission (continuous or intermittent) selection treatment.

The following conditions are suitable for the choice of high temperature ion incineration treatment program:

Organic matter content is high, the composition is complex, flammable and explosive (butadiene, etc.), more difficult to decompose substances such as carbon disulfide, containing particulate matter, oil, continuous high-dose discharge of industrial waste gas.

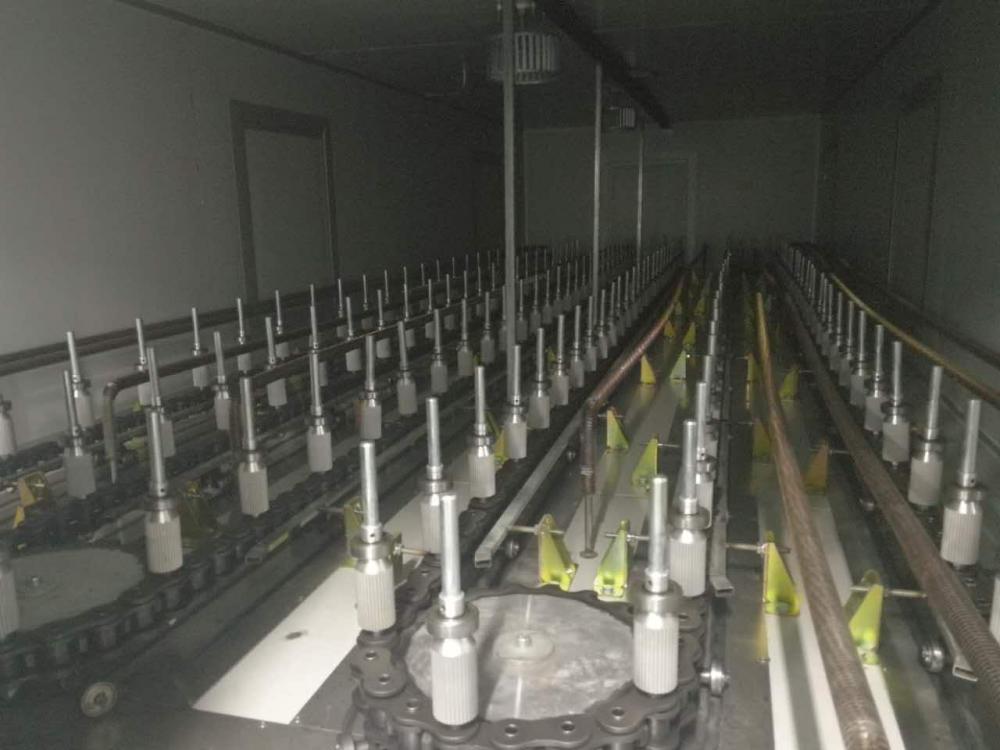

Such as gravure printing, offset printing, painting, chemical synthesis, petrochemical, flavor, spices and other industries.

The following circumstances need to increase the cyclone dust removal device:

Industrial emissions of particulate matter, such as coating industry emissions.

High temperature plasma incineration technology:

High temperature plasma incineration technology is high frequency (30KHz) high voltage (100KV) high power power in the specific conditions of the energy discharge, resulting in 3 thousand ℃ plasma high temperature air.

The gas to be treated is compressed in the reactor, and the high pressure concentrating discharge becomes a high temperature plasma. During the process of gas from the room temperature rose sharply to 3 thousand degrees high temperature, the reactor pressure increases, the gas volume and therefore a sharp expansion in a very short period of time to complete the material cracking process.

VOCs Emissions:

Benzene, toluene, xylene, styrene, butyl acetate, trimethy lolpropane triacrylate,

2-heptanone, hydroxycyclohexyl phenyl ketone, dimethyl polymer, triazine and ethylene oxide, hydroxyethyl methacrylate, pentaerythritol tetraacrylate

Several basic elements of governance options:

Depending on the composition of the exhaust gas (whether it contains moisture, solids, oily, and ease of handling), concentration (high, low), emission (continuous or intermittent) selection treatment.

The following conditions are suitable for the choice of high temperature ion incineration treatment program:

Organic matter content is high, the composition is complex, flammable and explosive (butadiene, etc.), more difficult to decompose substances such as carbon disulfide, containing particulate matter, oil, continuous high-dose discharge of industrial waste gas.

Such as gravure printing, offset printing, painting, chemical synthesis, petrochemical, flavor, spices and other industries.

The following circumstances need to increase the cyclone dust removal device:

Industrial emissions of particulate matter, such as coating industry emissions.

High temperature plasma incineration technology:

High temperature plasma incineration technology is high frequency (30KHz) high voltage (100KV) high power power in the specific conditions of the energy discharge, resulting in 3 thousand ℃ plasma high temperature air.

The gas to be treated is compressed in the reactor, and the high pressure concentrating discharge becomes a high temperature plasma. During the process of gas from the room temperature rose sharply to 3 thousand degrees high temperature, the reactor pressure increases, the gas volume and therefore a sharp expansion in a very short period of time to complete the material cracking process.

When the isothermal ion incineration treatment, the long molecular chain organic matter in the exhaust gas is split into elemental atoms. The main components of the exhaust gas of the treatment equipment are carbon dioxide and water vapor.

Related Keywords

Related Keywords