2 In 1 Small Size Shrink Packing Machine

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

2 In 1 Small Size Shrink Packing Machine To Different Country!!!  Product Description Application 1. This machine is widely used in toys, hardware, food, electronics and medicine. It will pack well as cover the transparent adhesion film on the carton or on the product surface. 2. Suitable material: POF,PVC,PP,PE,etc Parameters

Product Description Application 1. This machine is widely used in toys, hardware, food, electronics and medicine. It will pack well as cover the transparent adhesion film on the carton or on the product surface. 2. Suitable material: POF,PVC,PP,PE,etc Parameters

Main features

Main features

1. Integrated sealing and shrinking in one step 2. Transparent hood makes the sealing and shrinking visible 3. It furnished special roller with pin to make small holes on the film 4. Might not make over hot around environment after long time operation Advantages: 1,2 in 1 function :Integrated sealing and shrinking in one step 2, Transparent hood makes the sealing and shrinking visible 3, sealing glass fiber flutes, anti-stick temperature nickel-chromium alloy seal cutter, sealing neat cracking, coking; 4, equipped with special rollers pinhole device, fully drain the membrane air; 5, sliding film holder can be placed on a variety of shrink film, any adjustment; 6, power consumption, average hourly power consumption is only 3.5kw; 7, PPS knife chuck temperature materials, can withstand the test of long-term use; 8, can be adjusted according to the level of the tangential seal packaging size; 9, the bottom with lockable casters, may need to move or locate the machine; Shrinking samples:

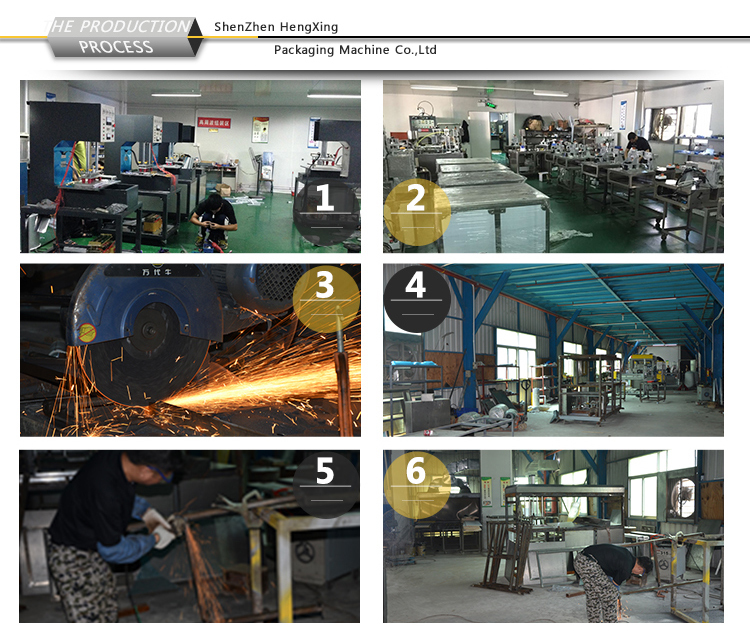

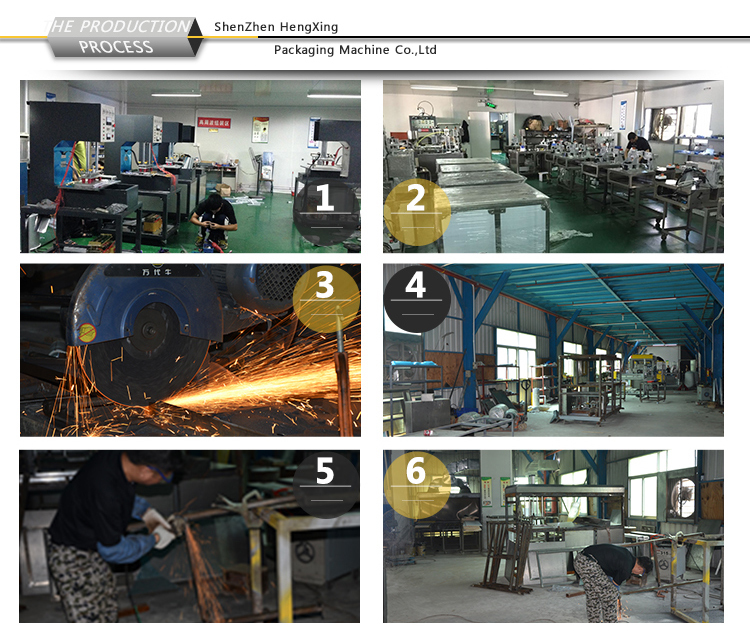

Factory View:

Factory View:  Company Information

Company Information

Packaging & Shipping

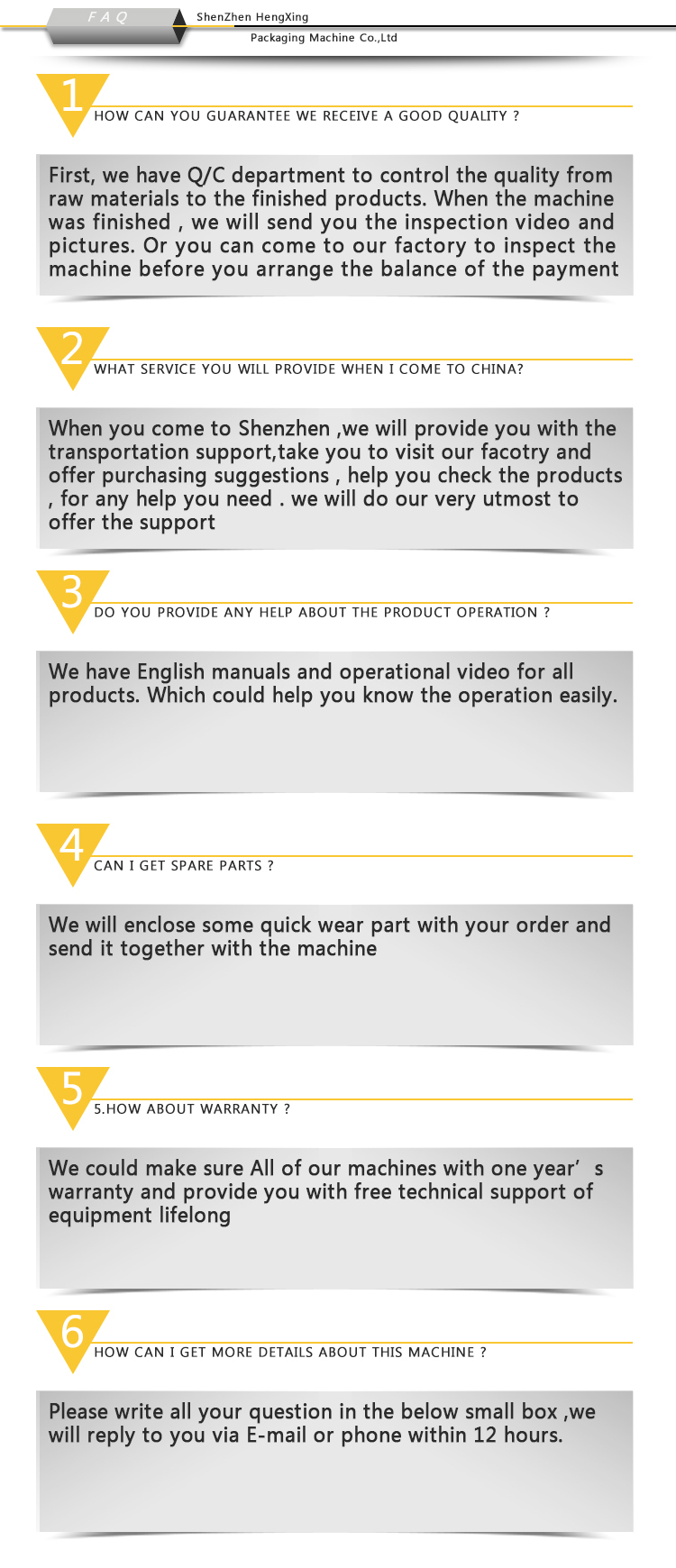

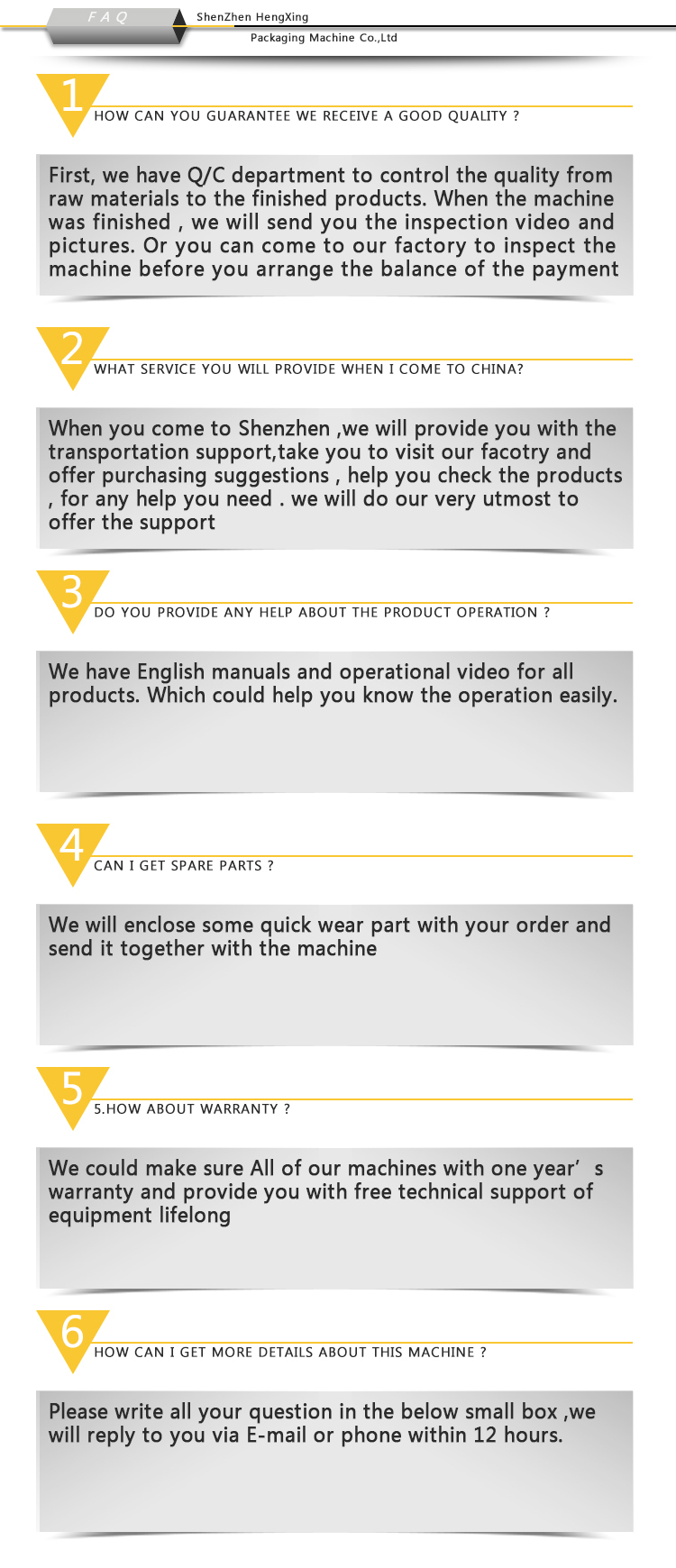

Packaging & Shipping  FAQ

FAQ  Name card

Name card

Product Description Application 1. This machine is widely used in toys, hardware, food, electronics and medicine. It will pack well as cover the transparent adhesion film on the carton or on the product surface. 2. Suitable material: POF,PVC,PP,PE,etc Parameters

Product Description Application 1. This machine is widely used in toys, hardware, food, electronics and medicine. It will pack well as cover the transparent adhesion film on the carton or on the product surface. 2. Suitable material: POF,PVC,PP,PE,etc Parameters Model | HX-5540 |

Power supply | 220V/50Hz |

Power | 2.5KW |

Capacity | 500-800pcs/H |

Max shrinking size | 550*420*300mm |

Machine size | 1450*700*1140mm |

Weigh (NET/GROSS) | 125/150KGS |

Main features

Main features1. Integrated sealing and shrinking in one step 2. Transparent hood makes the sealing and shrinking visible 3. It furnished special roller with pin to make small holes on the film 4. Might not make over hot around environment after long time operation Advantages: 1,2 in 1 function :Integrated sealing and shrinking in one step 2, Transparent hood makes the sealing and shrinking visible 3, sealing glass fiber flutes, anti-stick temperature nickel-chromium alloy seal cutter, sealing neat cracking, coking; 4, equipped with special rollers pinhole device, fully drain the membrane air; 5, sliding film holder can be placed on a variety of shrink film, any adjustment; 6, power consumption, average hourly power consumption is only 3.5kw; 7, PPS knife chuck temperature materials, can withstand the test of long-term use; 8, can be adjusted according to the level of the tangential seal packaging size; 9, the bottom with lockable casters, may need to move or locate the machine; Shrinking samples:

Factory View:

Factory View:  Company Information

Company Information

Packaging & Shipping

Packaging & Shipping  FAQ

FAQ  Name card

Name card

Related Keywords

Related Keywords

You May Also Like

You May Also Like