Clear Epoxy Resin for Table Top Finish

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

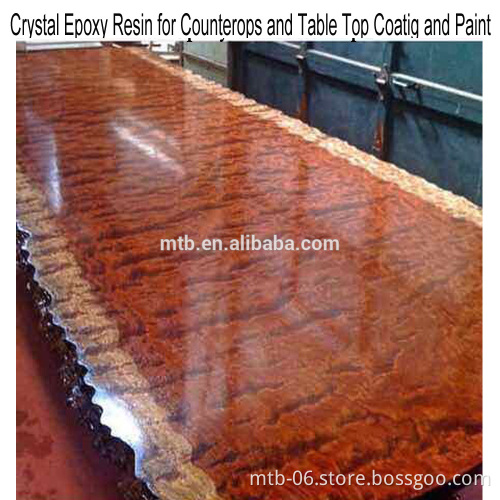

Product Description  MTB-3309 Urethane Varnish Top Coating ---Top Layerof Self Leveling Clear Epoxy Resin Top Coating and Paint

MTB-3309 Urethane Varnish Top Coating ---Top Layerof Self Leveling Clear Epoxy Resin Top Coating and Paint

Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc.

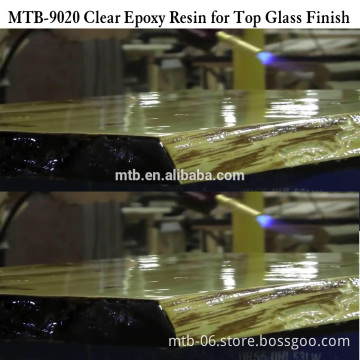

In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter like glass .

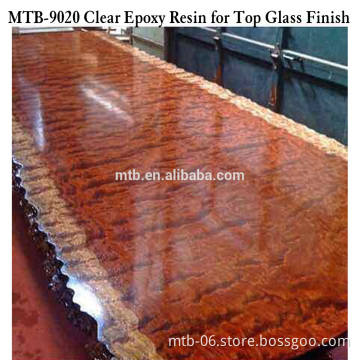

It is your best choice for your old furniture renovation to have a new face. Appplication ---Used for professional epoxy top coat on the wood materials,marble and tile topcoat

The Perfect Floor Systerm For Wood material top Tables Bar Top Kitchen Countertops Old Furniture Renovation and Reparing

Features Features -Clear ,two components of epoxy resin and hardener with the mix ratio of 2:1

-A type of epoxy resin for top layer self leveling paint construction

-Can mix with colors ,epecially metallic colors if you need

-Excellent operation performance

-Excellent performance, good flowing property

-Can achieve the mirror effect with high glossy effect and brightness after drying completely

-Has good mechanical properties

-Enough operation time

-After curing ,with excellent comprehensive performance , long-term to maintain good physical properties.

Technical Data Sheet

Using Directions Instruction

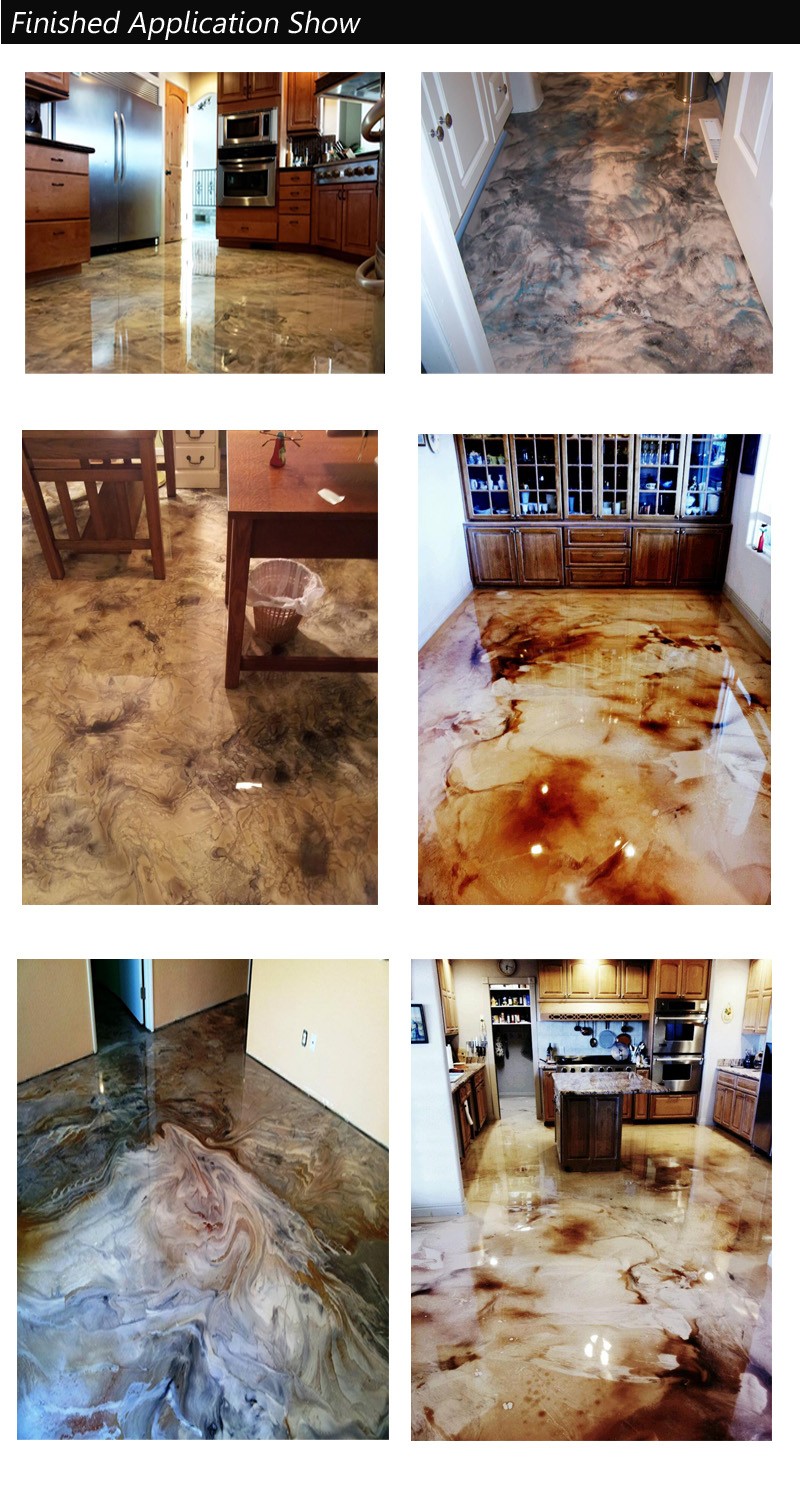

For the whole process of Epoxy Resin floor systems,there are 3 sets which is enough for floor coating and painting ,these are belows.

It is the perfect finish for any wood tops ,marble tops, our 100% Solid Epoxy Resin is not only ideal for Industrial and Commercial projects but also for Domestic areas such as wood ,bar,countertop,table ,furniture ,and so on.

Its high gloss finish reflects light beautifully thus visually enhancing the look, style, appearance and size of any tops.

Mixed together with our Metallic Pigment you can create a unique one of a kind tops tailored to your individual tastes and requirements.

MTB-3307 Epoxy Primer--Coating on the wood surface itself and coating permeability can strengthen the adhesion. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 1:1 .To fill on the cracks and holes of the wood to make the surface smoothly and bond tight to avoid peel off easily after period of time.

---MTB-3308 Epoxy Base coat ----It greatly enhance coating wood top coat with wear-resisting degree, density, improve the service life and make the perfect transition between the bottom and the surface layer. To make your wood top coat colorful as what you need. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1 When you use ,you can mix with any colors you need,if you want to get the mixed color effect,you can coat more times .

--MTB-3309Urethan Epoxy Self-level Surface Coating Layer or Top layer Coating (Varnish)--Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.

Notes: ---If you want clear finished effect on wood top ,pls use MTB-3307 and MTB-3309

---If you need the color finished effect on wood top or cover the old tops color, pls use MTB-3307,MTB-3308(mix with color ) and MTB-3309 ---If you have cost control,please use MTB-3309 ---If your tops are smooth enough and without any cracks or holes,and you need clear effect ,please use MTB-3309,if need colorful effect,pls use MTB-3308 and MTB-3309

Operation Steps Step 1. Prepare the surface.

Preparation of the substrate is necessary in order to ensure adhesion between the epoxy product and the substrate. Suitable methods are sanding or diamond-grinding. Any surfaces that have been contaminated with oils may also require chemical cleaning.

Step 2. Cleaning of the Tops The tops must be cleaned of all dusts and residues before starting to prime. Otherwise you will have various particles trapped within the coat and adhesion will be significantly weakened. The less micro-dust on the surface the less primer you will need. Step 3. Prime the floor with a suitable epoxy primer of MTB-3327

Always prime the tops, don’t believe claims that priming is not necessary. Priming will give your tops a longer life and better adhesion to the substrate. Priming will seal the substrate thus eliminating the risks of bubbles and gasses. Priming helps reduce the amount of product that will be required in the later stages. Ensure that the areas are ventilated properly. It is common to coat one or two layers of primer in order to properly seal the tops.Use a proper electrical mixer to mix the A and B component of the primer.

Once mixed,pour the product in a random pattern across the area . Using a notched squeegee spread the product gently around until you have an even coat on the tops surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

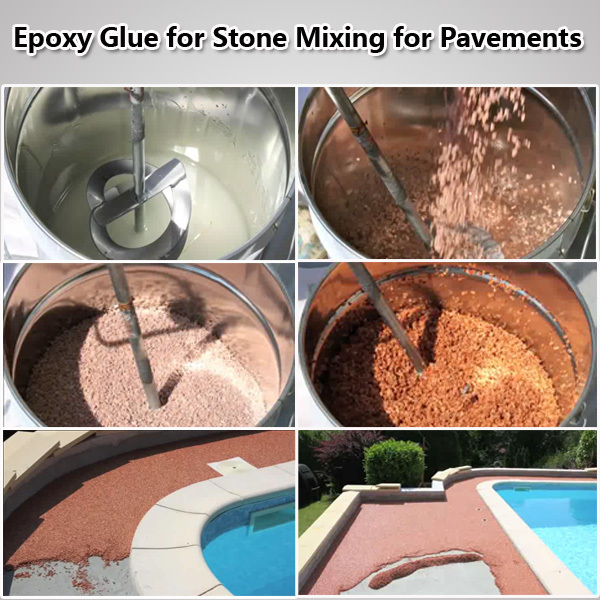

Step 4. Mixing of Epoxy Resin--MTB-3308 Color Middle Layer Coating

Empty all the contents of the Metallic Pigment with the hardener (part B) and mix for 3 minutes. Follow this by then mixing the hardener with the Epoxy component (part A). Use an electrical mixer and mix at least for 3 minutes. Don’t skimp on the mixing! This step is very important. Poor mixing will lead to a tacky floor! Leave to settle for a few minutes allow bubbles to disperse.

Once mixed pour the product in a random pattern across the area you wish to apply your epoxy primer . Using a notched squeegee spread the product gently around until you have an even coat on the tops surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Notes:For the second layer coating ,it needs about 4-5 hours to dry ,so during the process if you find somewhere it is not so smooth ,you can get more MTB-3308 to roller ;The mix ration between the MTB-3308 and color pigment is 50:1,if you think the color is not so brighter as you need,you can roller for twice to make it darker and can do more times as you need ;you can use your fingers to touch if it is hard and not sticky with your hands or feed that means it dry ,then you can start the top layer of MTB-3309 Top Varnish Layer Coating

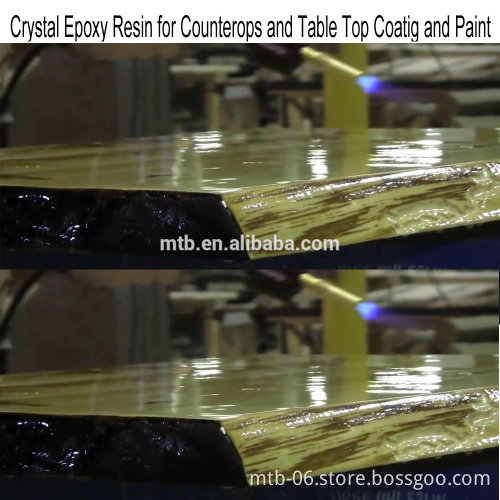

Step 6. Apply the MTB-3309 Top Varnish Coating

Mix Epoxy component (part A) with the hardener (part B), follow this by then mixing the hardener with the Use an electrical mixer and mix at least for 3 minutes. Don’t skimp on the mixing! This step is very important. Poor mixing will lead to a tacky floor! Leave to settle for a few minutes allow bubbles to disperse.

Once mixed pour the product in a random pattern across the area you wish to apply your Designer Epoxy foor Resin. Using a notched squeegee spread the product gently around until you have an even coat on the floors surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Notes:For the last layer coating ,it needs about 4-5 hours to dry ,so during the process if you find somewhere it is not so smooth ,you can get more MTB-3309 to roller ;In common ,it is clear ,but if you want to have a mixed color with the sencond layer ,you can also mix with the colors you need ;think the color is not so brighter as you need,you can roller for twice to make it darker and can do more times as you need ;you can use your fingers to touch if it is hard and not sticky with your hands or feed that means it dry ,then you can get the finished epoxy resin floor you need ,after 1-3 days you can use.

Notes:There are a variety of ways to create different finishes, please ask a member of our team or visit one of our approved training centres for training.

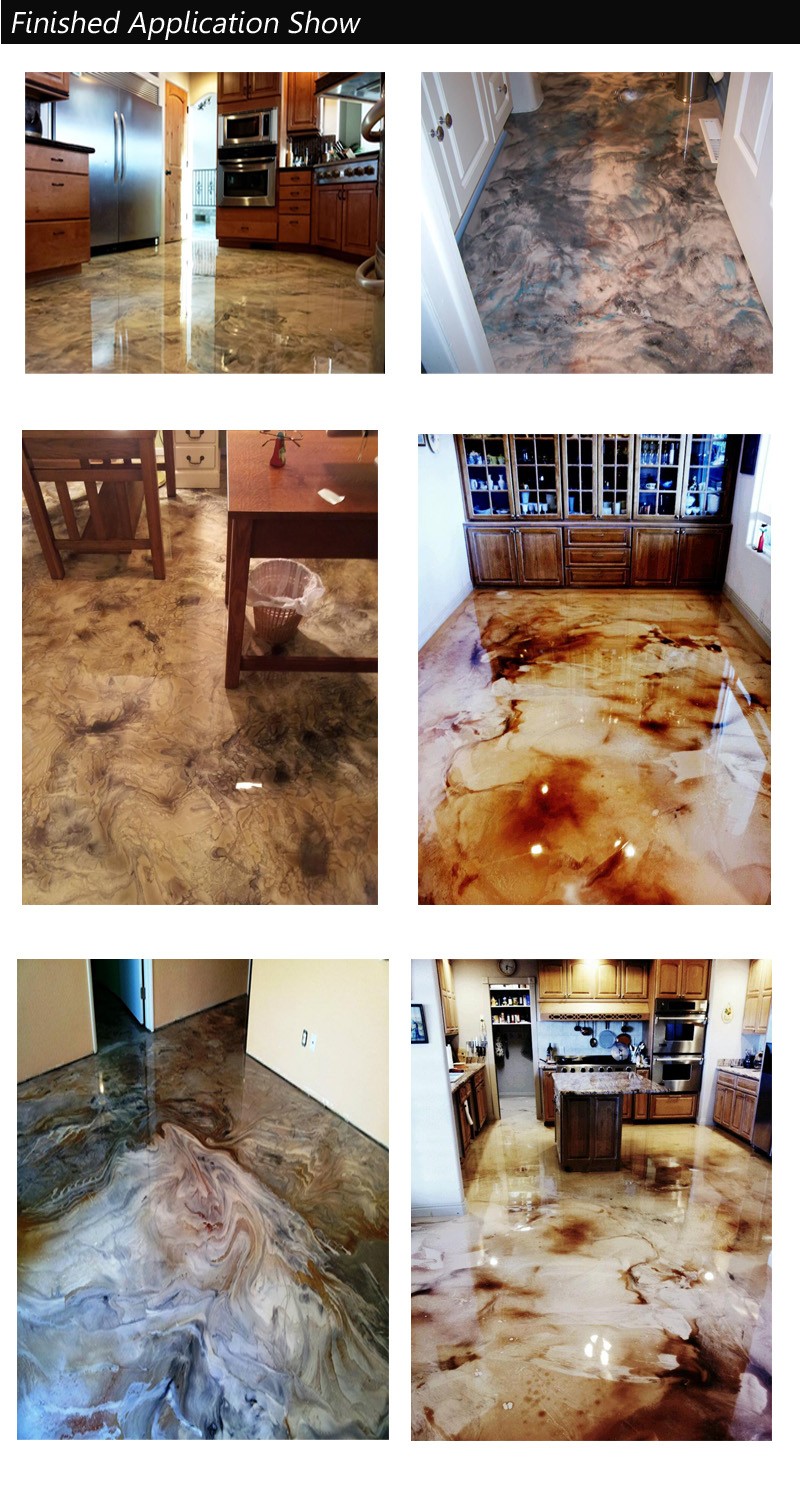

Detailed Images

Packing & Delivery

Packing & Delivery  Related Products

Related Products

MTB-3309 Urethane Varnish Top Coating ---Top Layerof Self Leveling Clear Epoxy Resin Top Coating and Paint

MTB-3309 Urethane Varnish Top Coating ---Top Layerof Self Leveling Clear Epoxy Resin Top Coating and PaintCan make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc.

In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter like glass .

It is your best choice for your old furniture renovation to have a new face. Appplication ---Used for professional epoxy top coat on the wood materials,marble and tile topcoat

The Perfect Floor Systerm For Wood material top Tables Bar Top Kitchen Countertops Old Furniture Renovation and Reparing

Features Features -Clear ,two components of epoxy resin and hardener with the mix ratio of 2:1

-A type of epoxy resin for top layer self leveling paint construction

-Can mix with colors ,epecially metallic colors if you need

-Excellent operation performance

-Excellent performance, good flowing property

-Can achieve the mirror effect with high glossy effect and brightness after drying completely

-Has good mechanical properties

-Enough operation time

-After curing ,with excellent comprehensive performance , long-term to maintain good physical properties.

Technical Data Sheet

For the whole process of Epoxy Resin floor systems,there are 3 sets which is enough for floor coating and painting ,these are belows.

It is the perfect finish for any wood tops ,marble tops, our 100% Solid Epoxy Resin is not only ideal for Industrial and Commercial projects but also for Domestic areas such as wood ,bar,countertop,table ,furniture ,and so on.

Its high gloss finish reflects light beautifully thus visually enhancing the look, style, appearance and size of any tops.

Mixed together with our Metallic Pigment you can create a unique one of a kind tops tailored to your individual tastes and requirements.

MTB-3307 Epoxy Primer--Coating on the wood surface itself and coating permeability can strengthen the adhesion. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 1:1 .To fill on the cracks and holes of the wood to make the surface smoothly and bond tight to avoid peel off easily after period of time.

---MTB-3308 Epoxy Base coat ----It greatly enhance coating wood top coat with wear-resisting degree, density, improve the service life and make the perfect transition between the bottom and the surface layer. To make your wood top coat colorful as what you need. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1 When you use ,you can mix with any colors you need,if you want to get the mixed color effect,you can coat more times .

--MTB-3309Urethan Epoxy Self-level Surface Coating Layer or Top layer Coating (Varnish)--Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.

Notes: ---If you want clear finished effect on wood top ,pls use MTB-3307 and MTB-3309

---If you need the color finished effect on wood top or cover the old tops color, pls use MTB-3307,MTB-3308(mix with color ) and MTB-3309 ---If you have cost control,please use MTB-3309 ---If your tops are smooth enough and without any cracks or holes,and you need clear effect ,please use MTB-3309,if need colorful effect,pls use MTB-3308 and MTB-3309

Operation Steps Step 1. Prepare the surface.

Preparation of the substrate is necessary in order to ensure adhesion between the epoxy product and the substrate. Suitable methods are sanding or diamond-grinding. Any surfaces that have been contaminated with oils may also require chemical cleaning.

Step 2. Cleaning of the Tops The tops must be cleaned of all dusts and residues before starting to prime. Otherwise you will have various particles trapped within the coat and adhesion will be significantly weakened. The less micro-dust on the surface the less primer you will need. Step 3. Prime the floor with a suitable epoxy primer of MTB-3327

Always prime the tops, don’t believe claims that priming is not necessary. Priming will give your tops a longer life and better adhesion to the substrate. Priming will seal the substrate thus eliminating the risks of bubbles and gasses. Priming helps reduce the amount of product that will be required in the later stages. Ensure that the areas are ventilated properly. It is common to coat one or two layers of primer in order to properly seal the tops.Use a proper electrical mixer to mix the A and B component of the primer.

Once mixed,pour the product in a random pattern across the area . Using a notched squeegee spread the product gently around until you have an even coat on the tops surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Step 4. Mixing of Epoxy Resin--MTB-3308 Color Middle Layer Coating

Empty all the contents of the Metallic Pigment with the hardener (part B) and mix for 3 minutes. Follow this by then mixing the hardener with the Epoxy component (part A). Use an electrical mixer and mix at least for 3 minutes. Don’t skimp on the mixing! This step is very important. Poor mixing will lead to a tacky floor! Leave to settle for a few minutes allow bubbles to disperse.

Once mixed pour the product in a random pattern across the area you wish to apply your epoxy primer . Using a notched squeegee spread the product gently around until you have an even coat on the tops surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Notes:For the second layer coating ,it needs about 4-5 hours to dry ,so during the process if you find somewhere it is not so smooth ,you can get more MTB-3308 to roller ;The mix ration between the MTB-3308 and color pigment is 50:1,if you think the color is not so brighter as you need,you can roller for twice to make it darker and can do more times as you need ;you can use your fingers to touch if it is hard and not sticky with your hands or feed that means it dry ,then you can start the top layer of MTB-3309 Top Varnish Layer Coating

Step 6. Apply the MTB-3309 Top Varnish Coating

Mix Epoxy component (part A) with the hardener (part B), follow this by then mixing the hardener with the Use an electrical mixer and mix at least for 3 minutes. Don’t skimp on the mixing! This step is very important. Poor mixing will lead to a tacky floor! Leave to settle for a few minutes allow bubbles to disperse.

Once mixed pour the product in a random pattern across the area you wish to apply your Designer Epoxy foor Resin. Using a notched squeegee spread the product gently around until you have an even coat on the floors surface. Then use a good quality roller, as poor quality rollers may start to shed or spiked roller and back roll the product (be careful not to over do this process as colours will merge into 1 if over rolled)

Notes:For the last layer coating ,it needs about 4-5 hours to dry ,so during the process if you find somewhere it is not so smooth ,you can get more MTB-3309 to roller ;In common ,it is clear ,but if you want to have a mixed color with the sencond layer ,you can also mix with the colors you need ;think the color is not so brighter as you need,you can roller for twice to make it darker and can do more times as you need ;you can use your fingers to touch if it is hard and not sticky with your hands or feed that means it dry ,then you can get the finished epoxy resin floor you need ,after 1-3 days you can use.

Notes:There are a variety of ways to create different finishes, please ask a member of our team or visit one of our approved training centres for training.

Detailed Images

Packing & Delivery

Packing & Delivery  Related Products

Related Products