Black Self Leveling Epoxy resin for Electronic Encapsulation and Potting

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

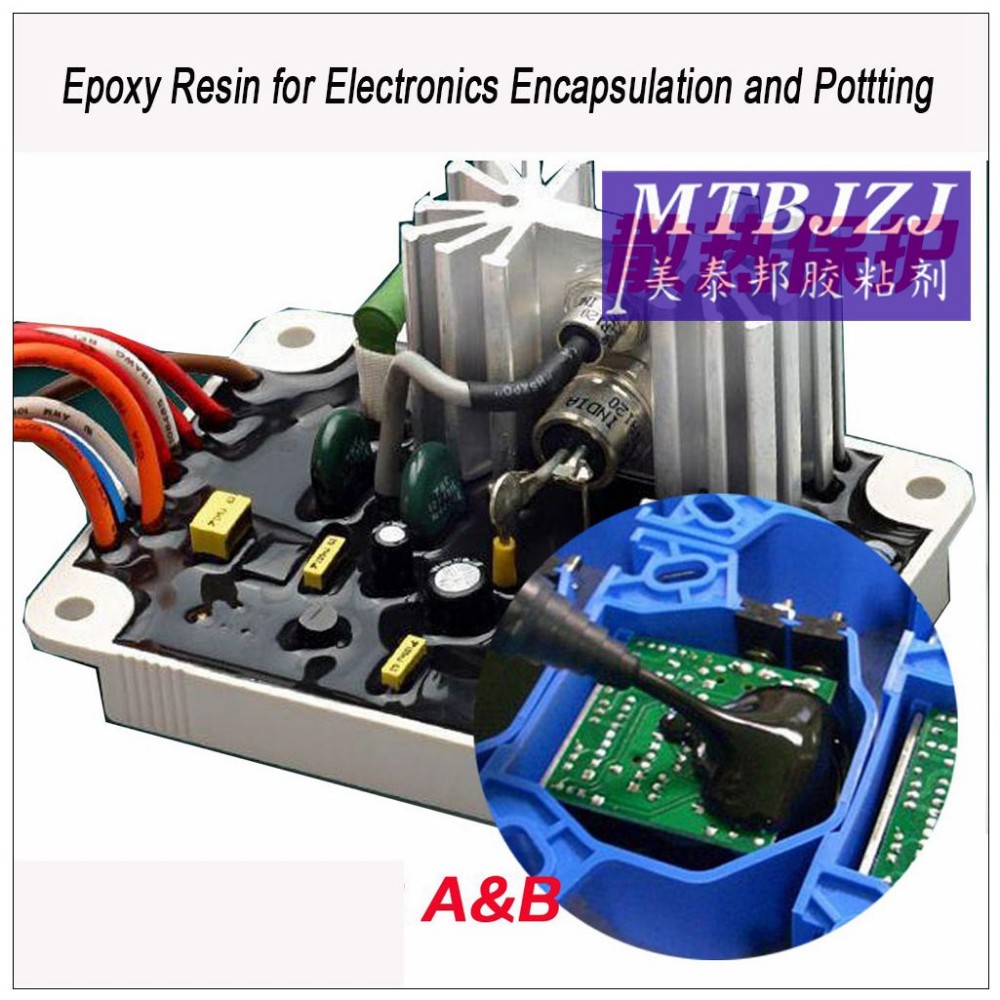

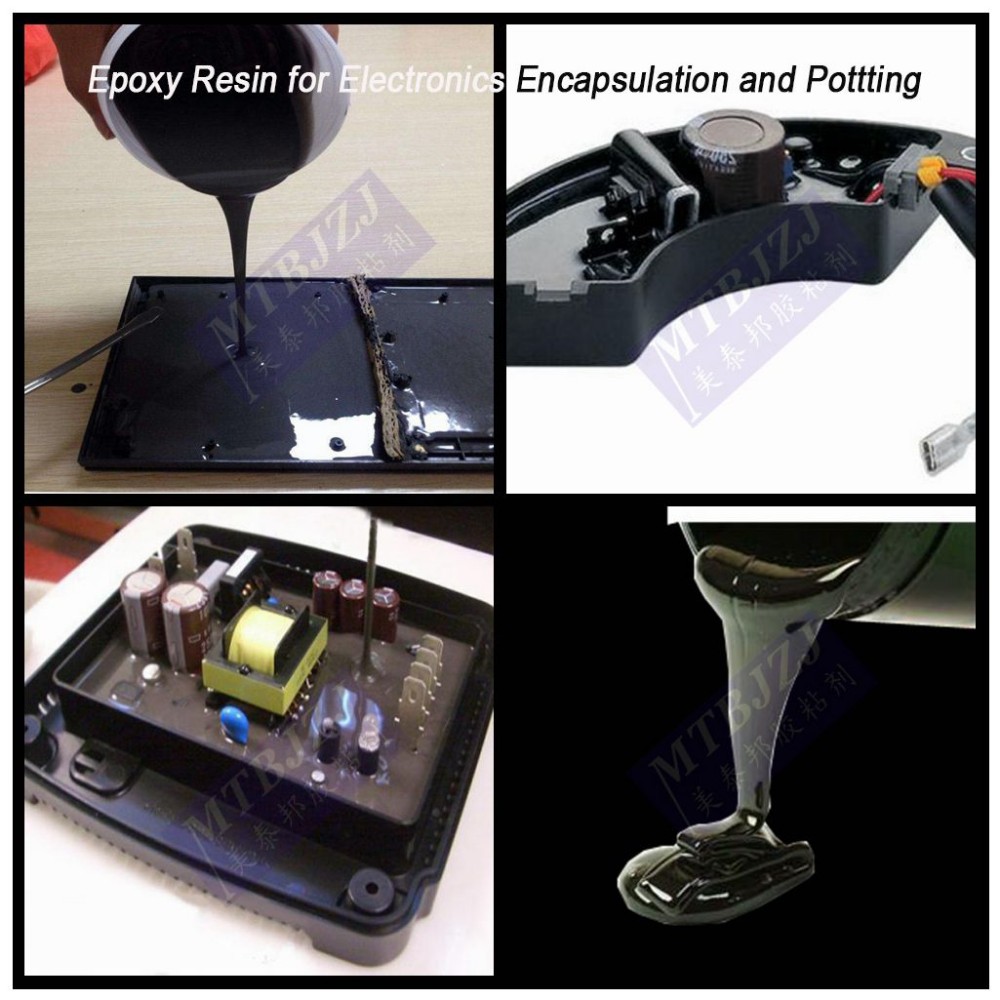

Product Description MTB-3301 Self Leveling Epoxy resin for Electronic Encapsulation and Potting

Character 1.Two componens of epoxy resin and hardener with the mix ratio of 4:1

Character 1.Two componens of epoxy resin and hardener with the mix ratio of 4:1

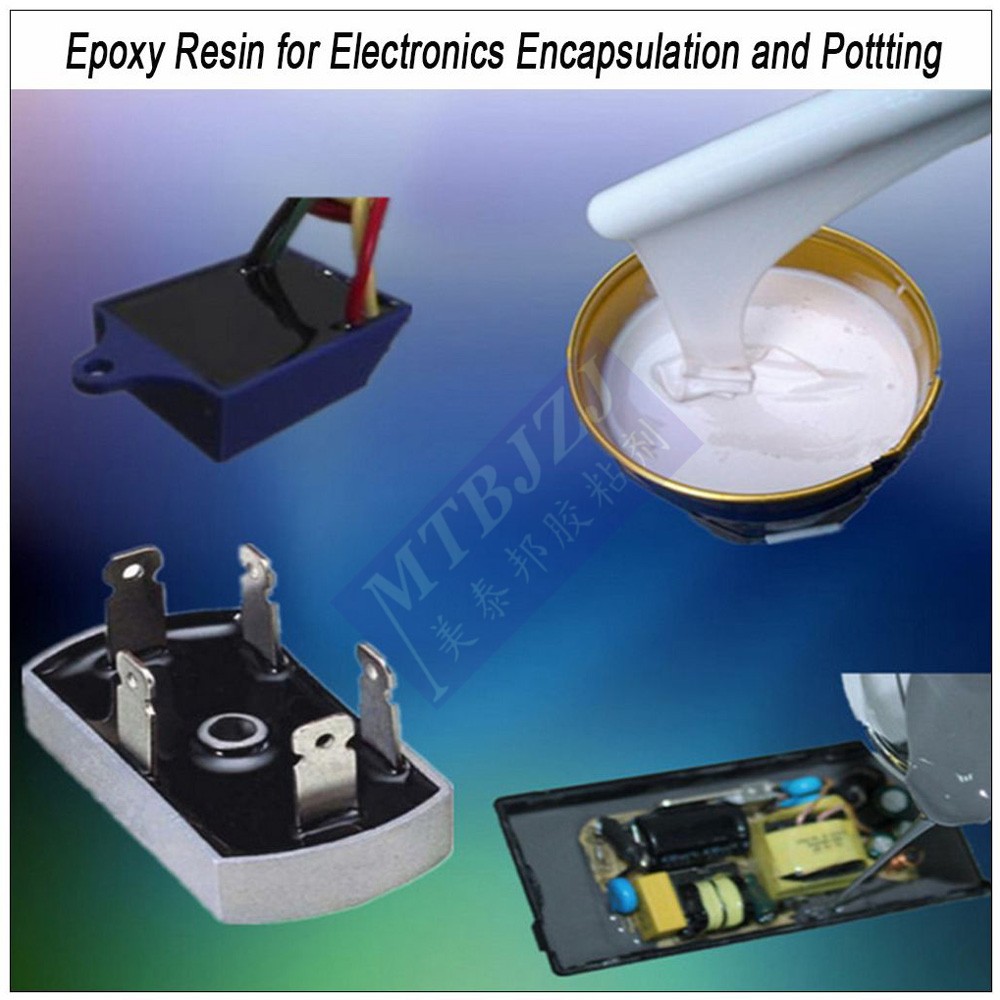

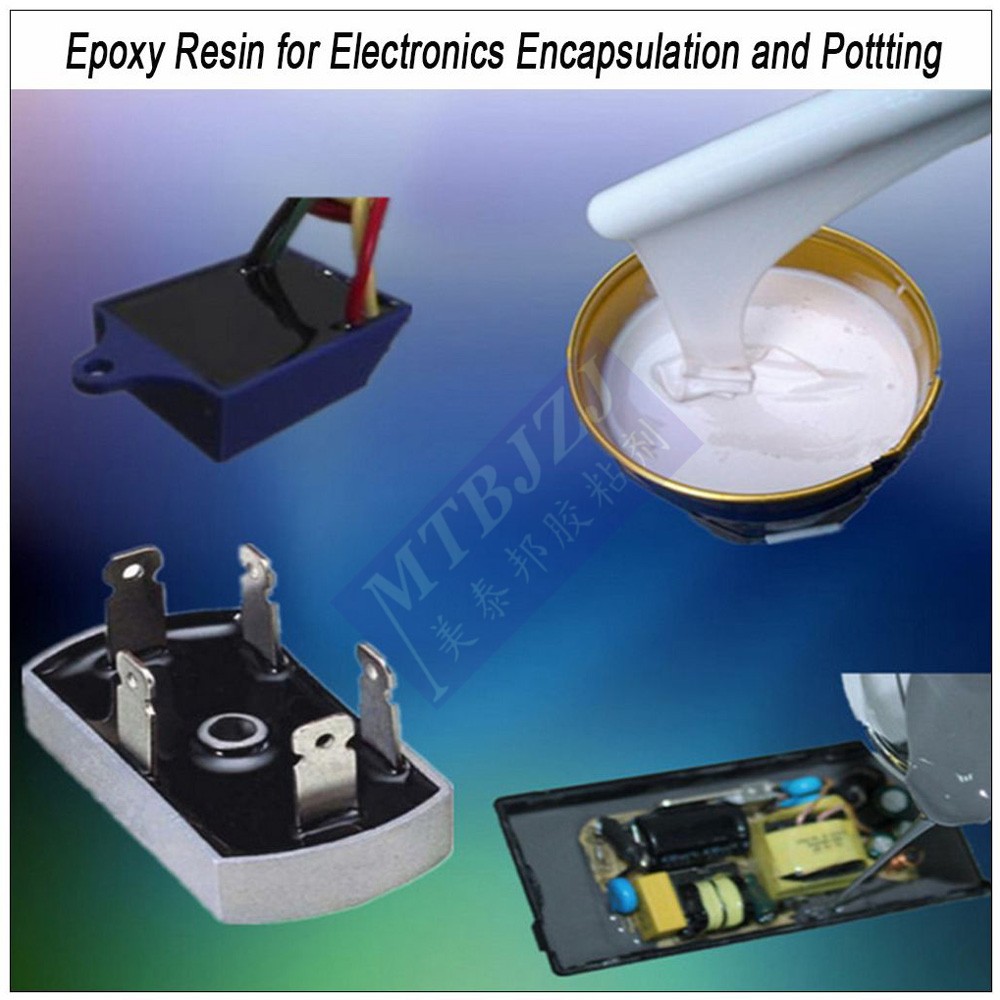

2.With the color of black, clear and milkwhite for your choice.

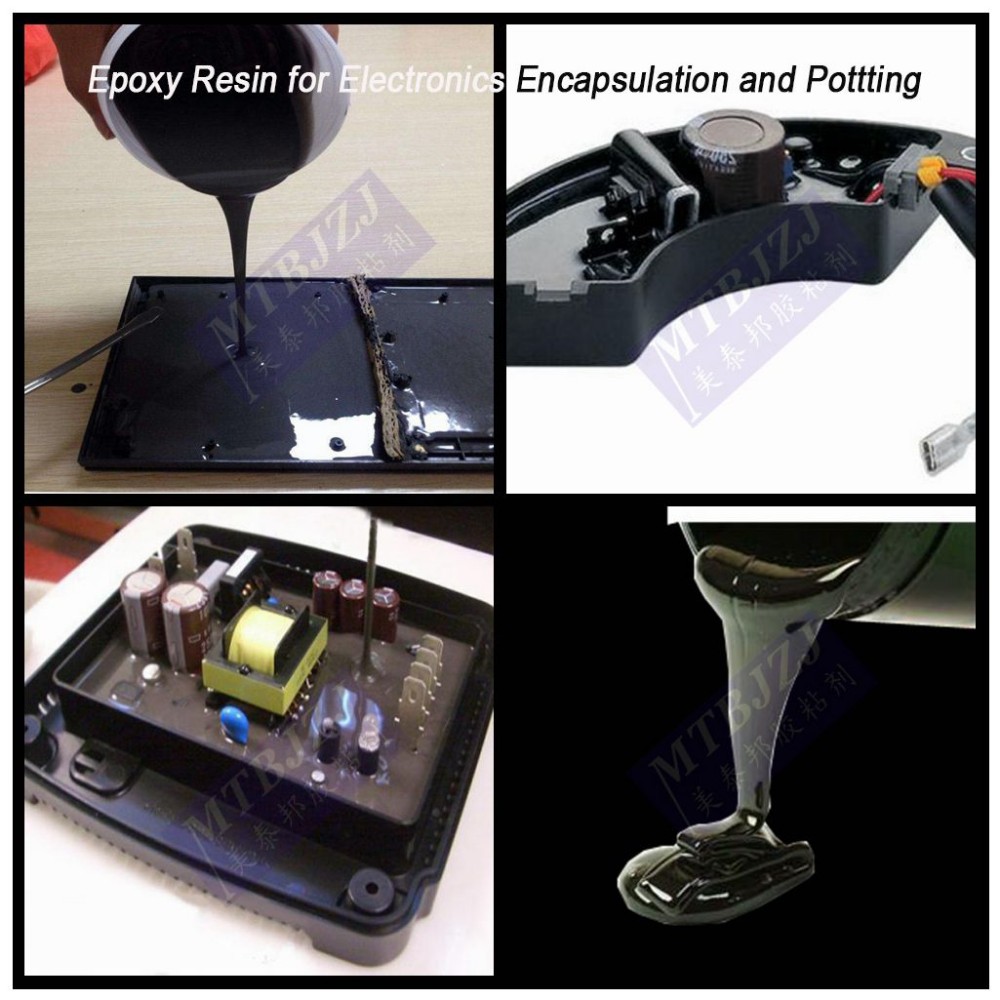

3.Good fluidity,high bonding strength and good physical features.

4.Good defoam performance ,no bubbles left after cured.

5.Excelllent Leveling and insulation,with good glossy and high hardness after dry.

6.Good fire resistance ,waterpoorf ,chemical ,oil,acid ,pressure and corrision resistance.

7.Good heat ,weather and mositure resistance .

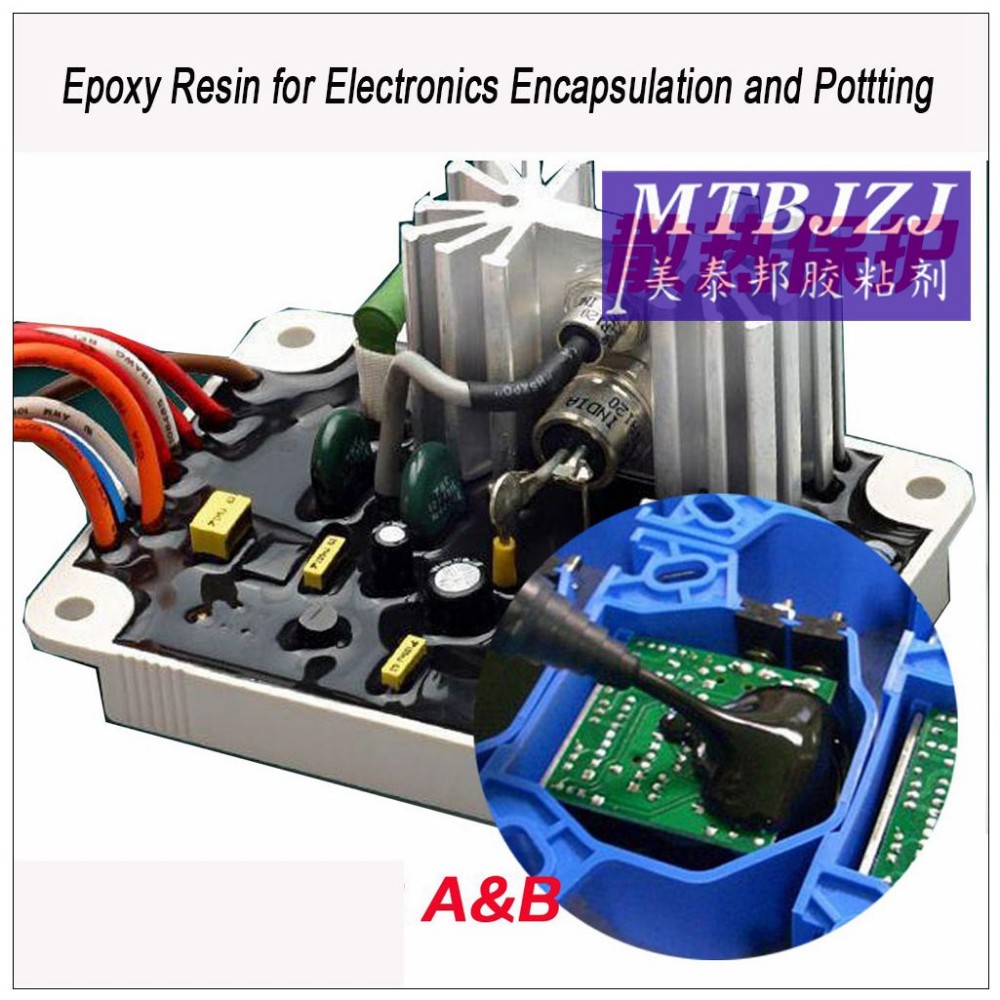

Application Apply on circuit board , capacitor, storage battery and kind of electronic product that need to pot ,sealant , waterproof, insulate and so on .

Technical Data

Technical Data

Cured Character 1.No bubbles, good flatness, good gloss, high hardness

2.Cured products with good flame retardant property

3.Good acid-base resistance

4.Good moisture, water, oil, dust resistance

5.Good resistance of humidity and weather aging

6. Good heat dissipation performance

Using Method

Step 1: Keep the product clean and dry, weight the A and B glue with the ratio of 4:1

Step 1: Keep the product clean and dry, weight the A and B glue with the ratio of 4:1

Step 2: Pour the A and B glue into a container ,Stir it fully to aviod cure incompletely

Step 3: Let it be for a moment to defoam (if there have the bubble ) ,and take a little to have a try After cured , it is hard and glossy

Our Advantages 1. Enviromental product

Our Advantages 1. Enviromental product

2.Quickly delivery

3.Competitive price (for we are direct manufacturer )

4.Professional manufacturer and long history (we are directly manufacturer of glue and adhesive since 1998)

5. Our product have been exported to so many countries

Packing & Delivery 5KGS/barrel,20kgs/set ( if you want ,we can do the package as your design.)

Packing & Delivery 5KGS/barrel,20kgs/set ( if you want ,we can do the package as your design.)

Character 1.Two componens of epoxy resin and hardener with the mix ratio of 4:1

Character 1.Two componens of epoxy resin and hardener with the mix ratio of 4:12.With the color of black, clear and milkwhite for your choice.

3.Good fluidity,high bonding strength and good physical features.

4.Good defoam performance ,no bubbles left after cured.

5.Excelllent Leveling and insulation,with good glossy and high hardness after dry.

6.Good fire resistance ,waterpoorf ,chemical ,oil,acid ,pressure and corrision resistance.

7.Good heat ,weather and mositure resistance .

Application Apply on circuit board , capacitor, storage battery and kind of electronic product that need to pot ,sealant , waterproof, insulate and so on .

Technical Data

Technical Data 2.Cured products with good flame retardant property

3.Good acid-base resistance

4.Good moisture, water, oil, dust resistance

5.Good resistance of humidity and weather aging

6. Good heat dissipation performance

Using Method

Step 1: Keep the product clean and dry, weight the A and B glue with the ratio of 4:1

Step 1: Keep the product clean and dry, weight the A and B glue with the ratio of 4:1Step 2: Pour the A and B glue into a container ,Stir it fully to aviod cure incompletely

Step 3: Let it be for a moment to defoam (if there have the bubble ) ,and take a little to have a try After cured , it is hard and glossy

Our Advantages 1. Enviromental product

Our Advantages 1. Enviromental product2.Quickly delivery

3.Competitive price (for we are direct manufacturer )

4.Professional manufacturer and long history (we are directly manufacturer of glue and adhesive since 1998)

5. Our product have been exported to so many countries

Packing & Delivery 5KGS/barrel,20kgs/set ( if you want ,we can do the package as your design.)

Packing & Delivery 5KGS/barrel,20kgs/set ( if you want ,we can do the package as your design.)

Related Keywords

Related Keywords