Scratch Resistant Epoxy Coating for Table tops

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

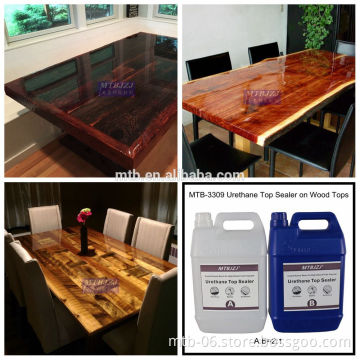

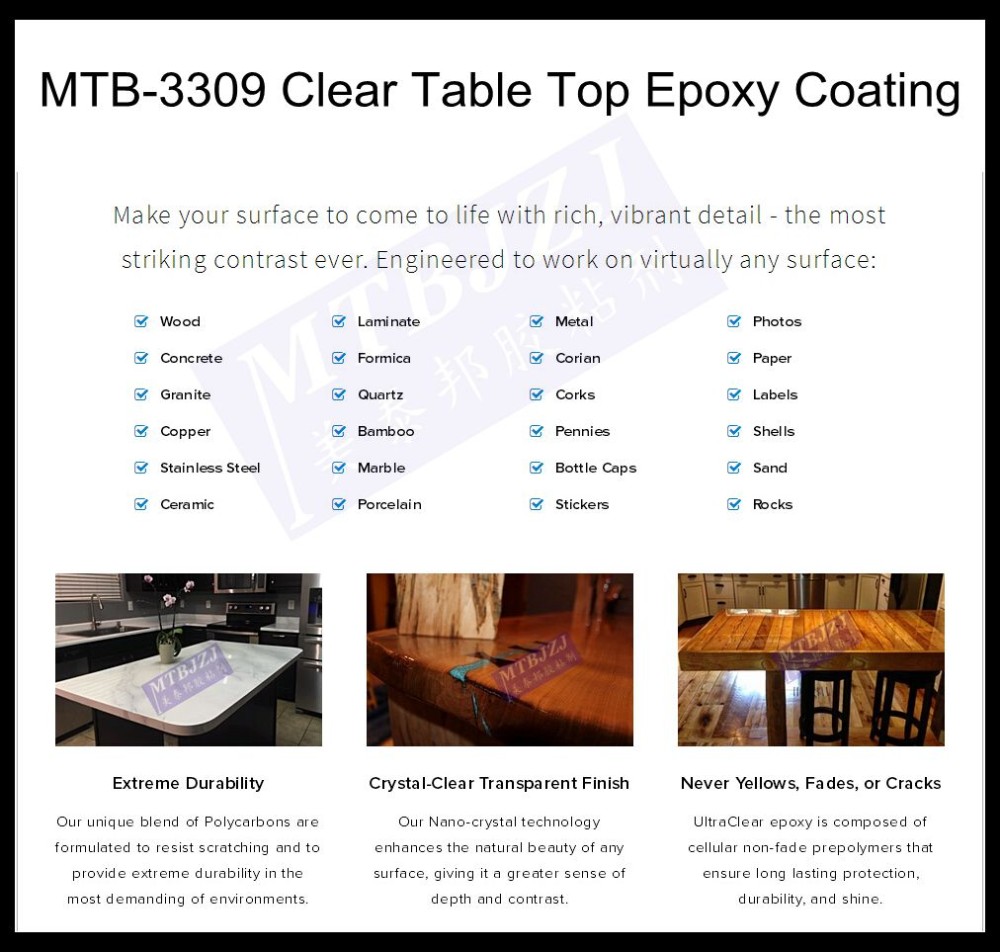

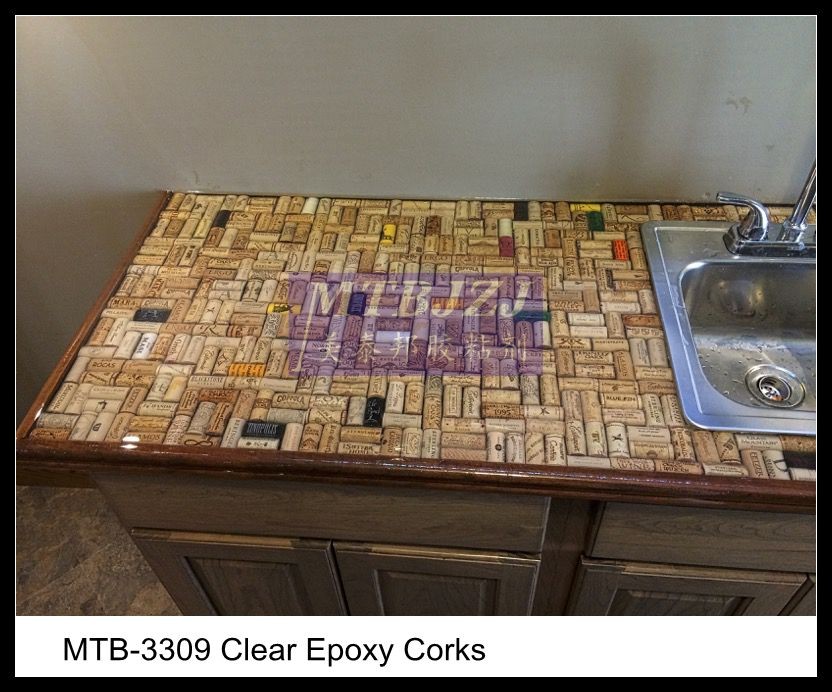

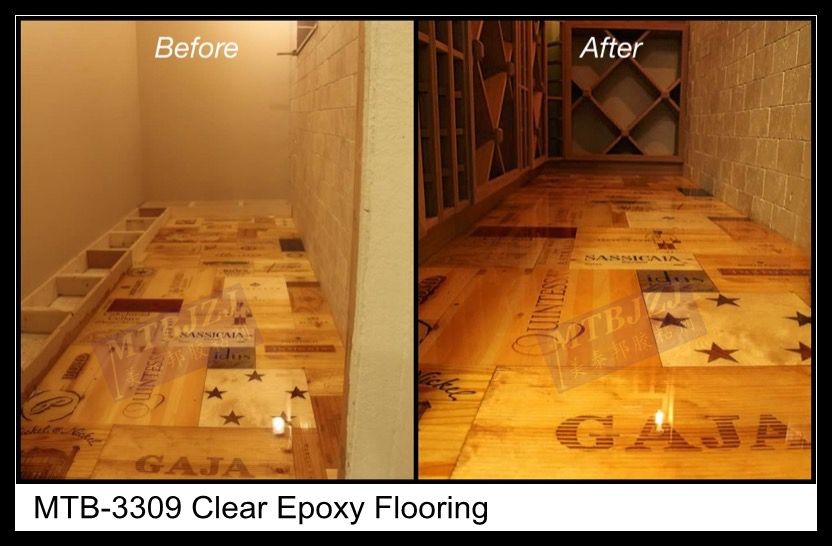

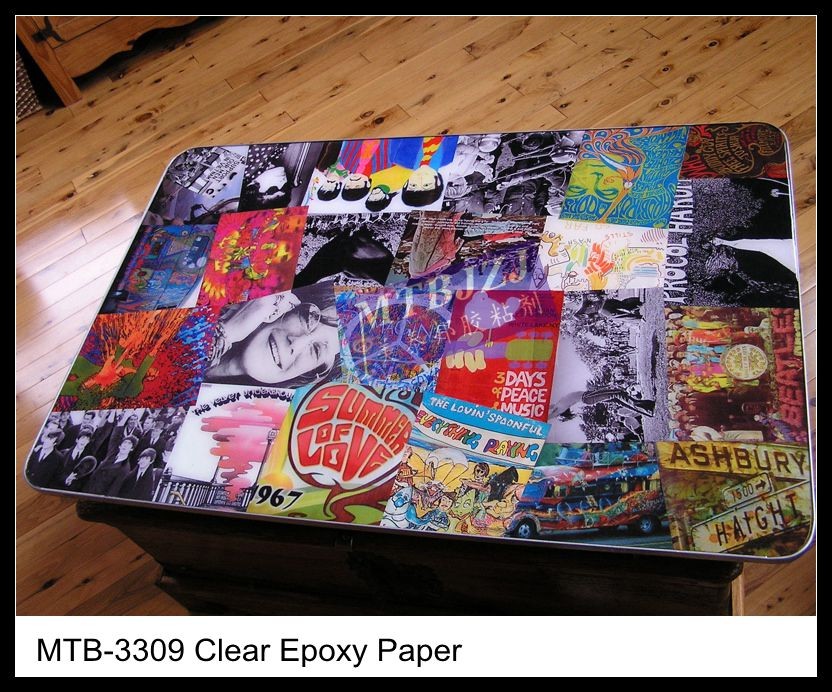

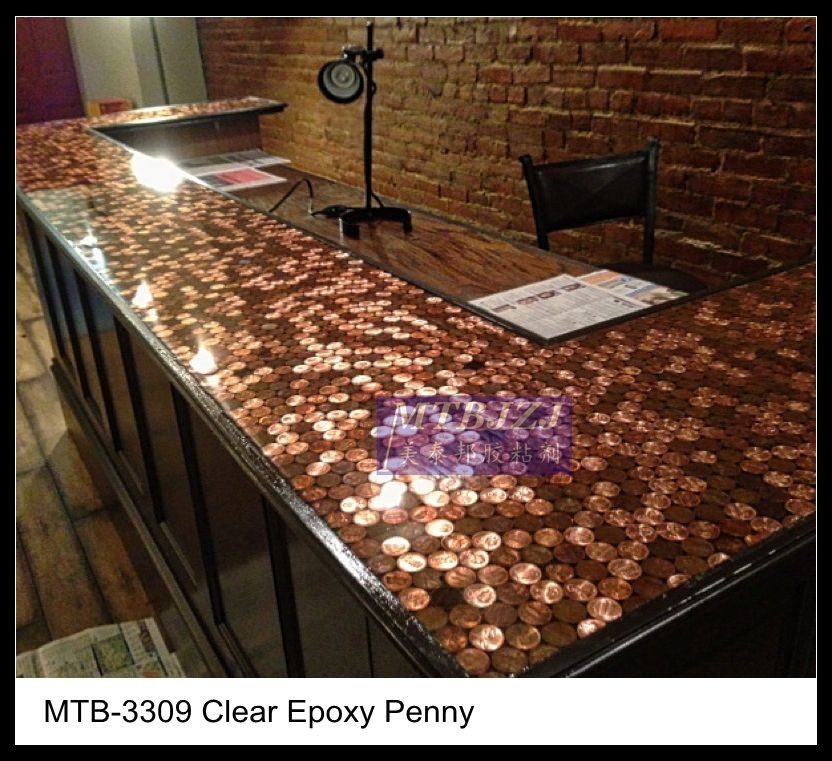

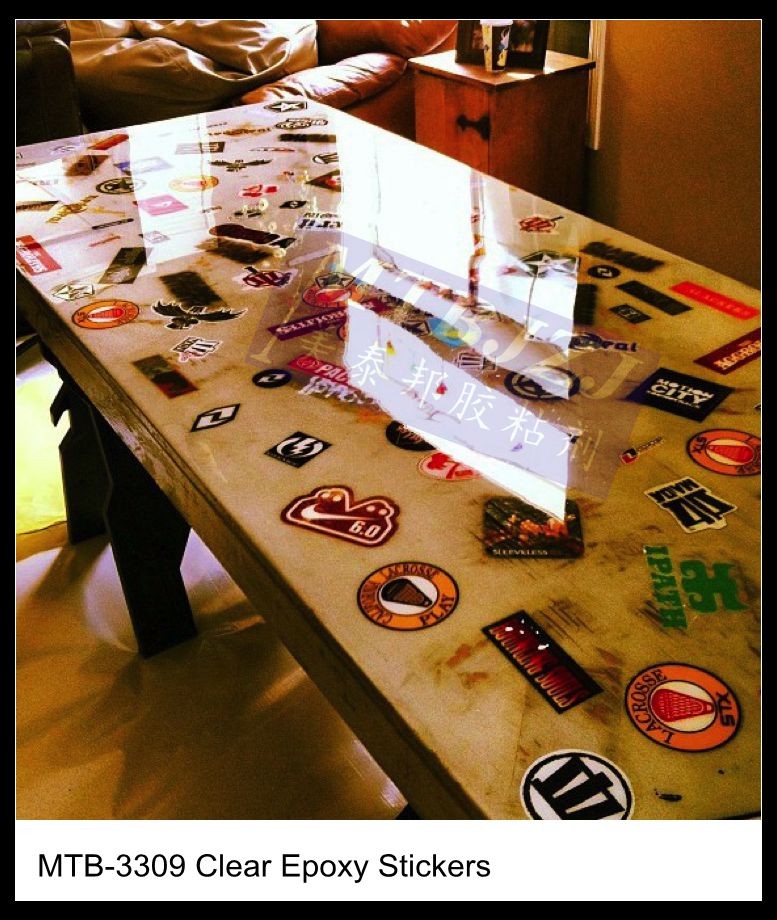

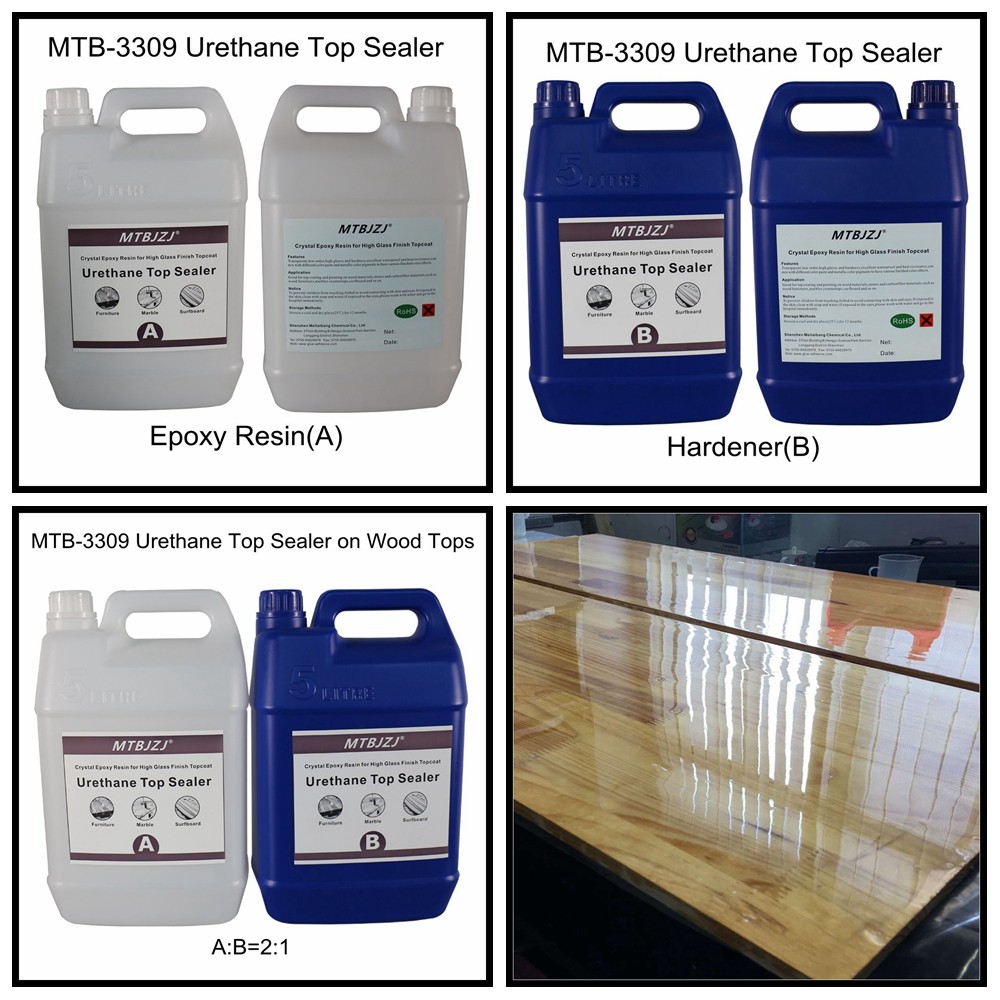

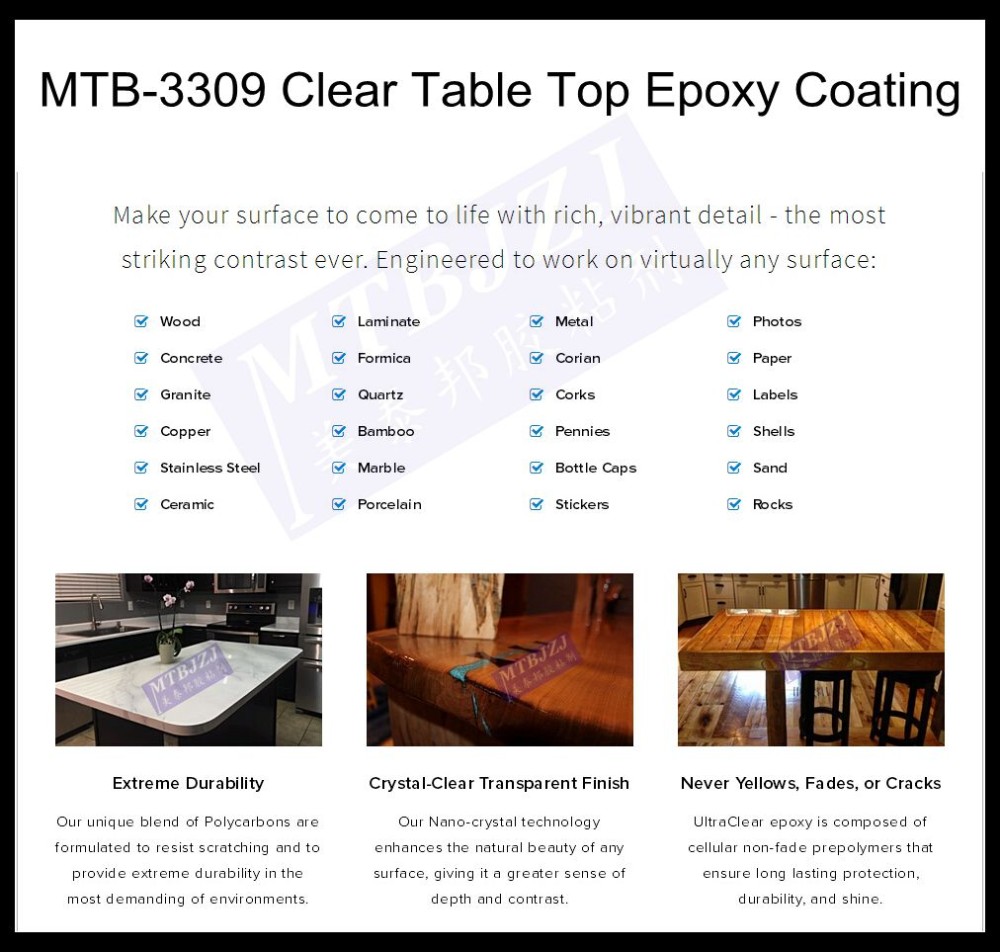

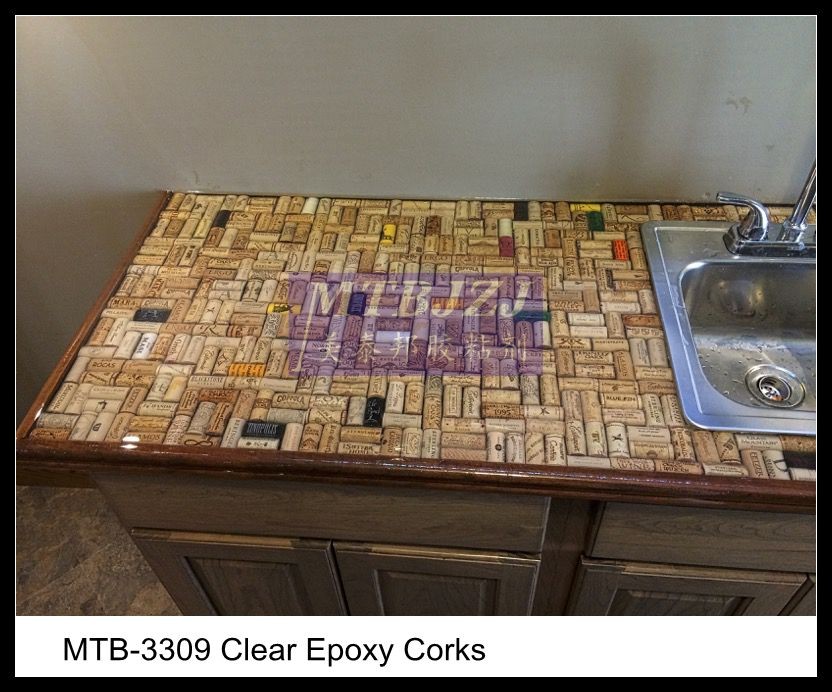

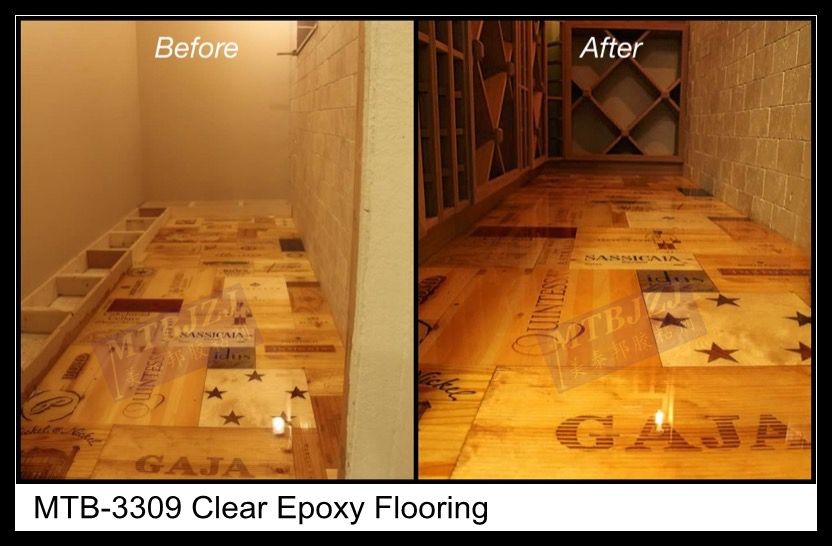

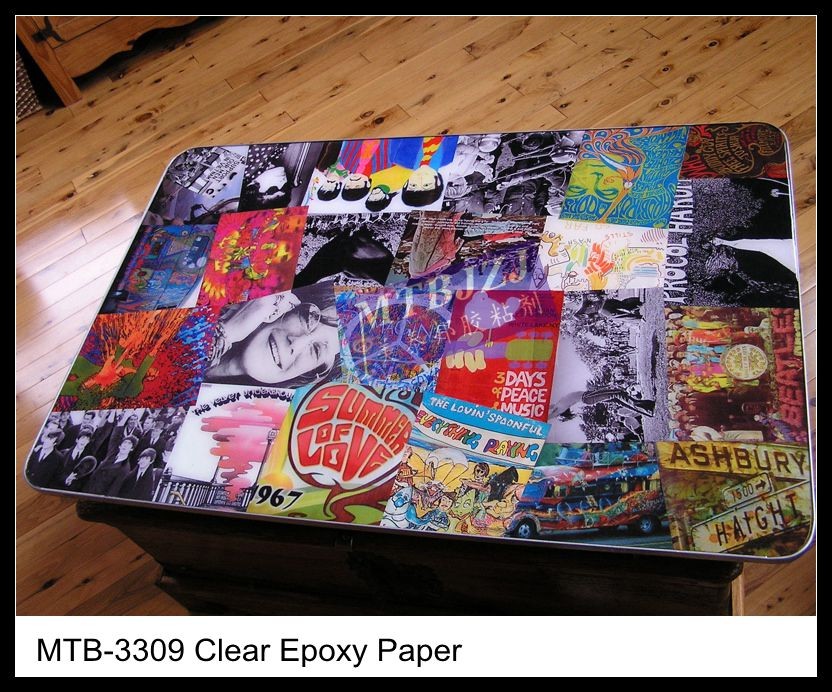

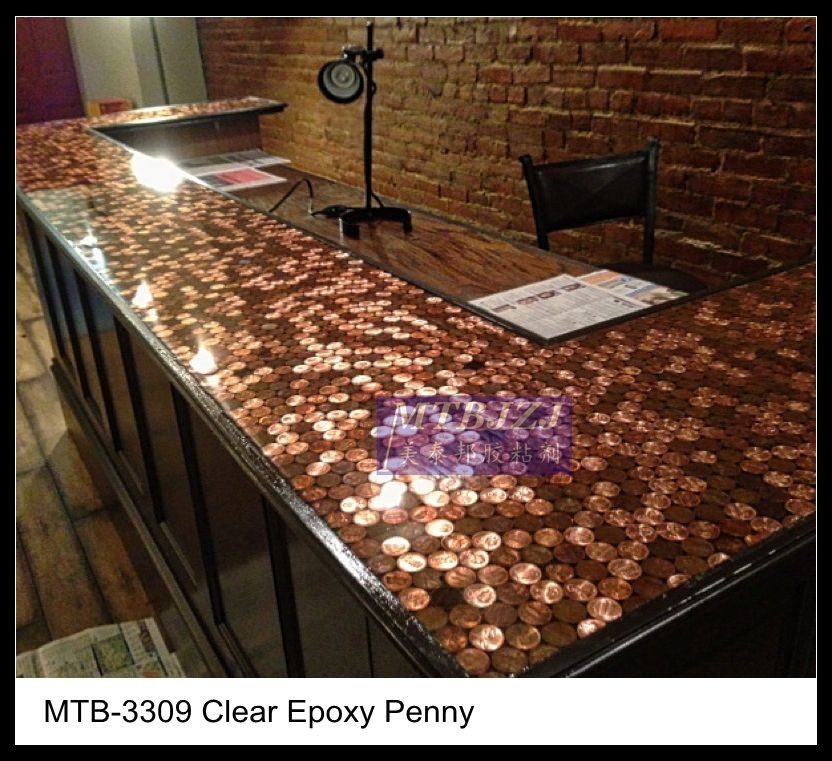

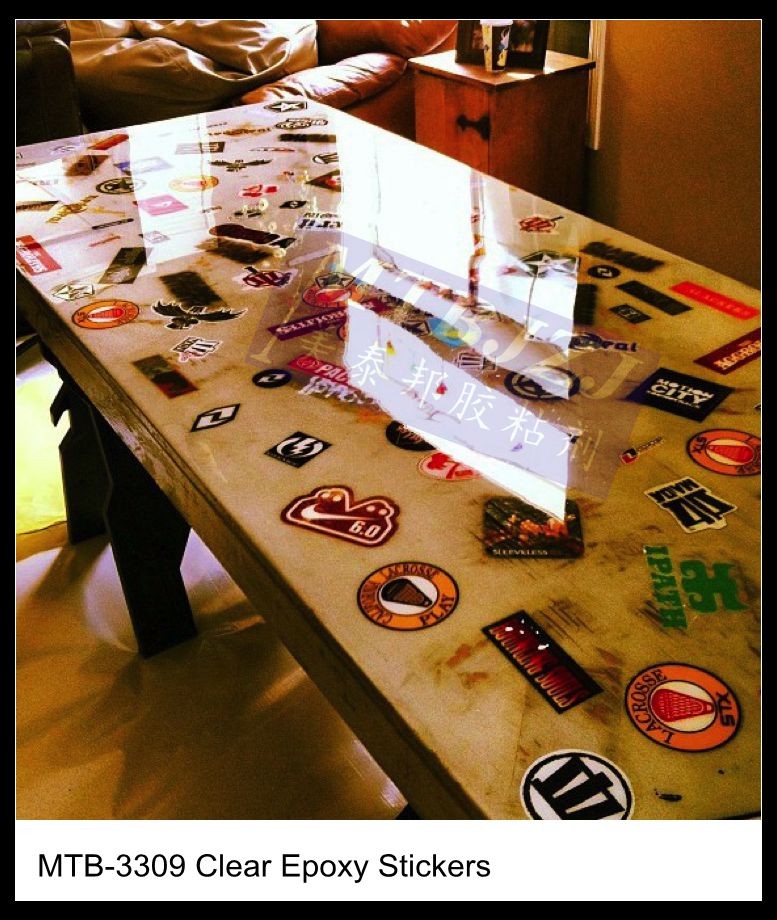

Product Description MTB-3309 Ultra Clear Countertop Epoxy Coating /Extremely Durable Table Top Finish

The most advanced epoxy coating on the market.

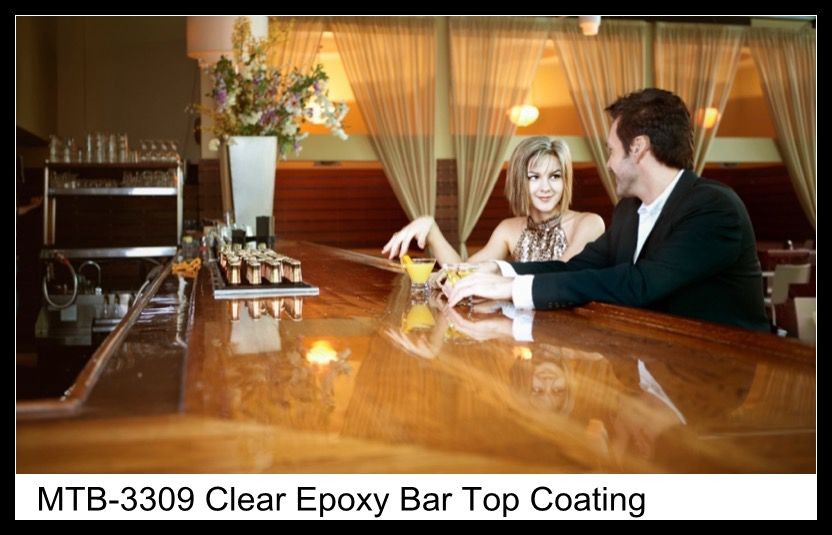

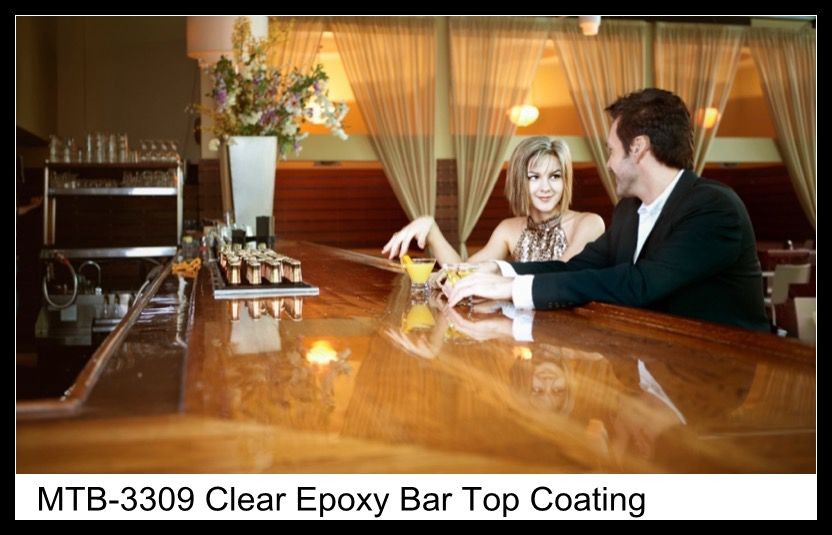

Ultra Clear epoxy boasts the most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever. The most sophisticated system of synthetic polymeric-based protection available. Our Commercial-grade epoxy is engineered specifically for Bar Tops, Tabletops & Countertops.

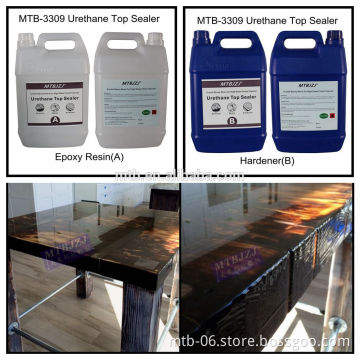

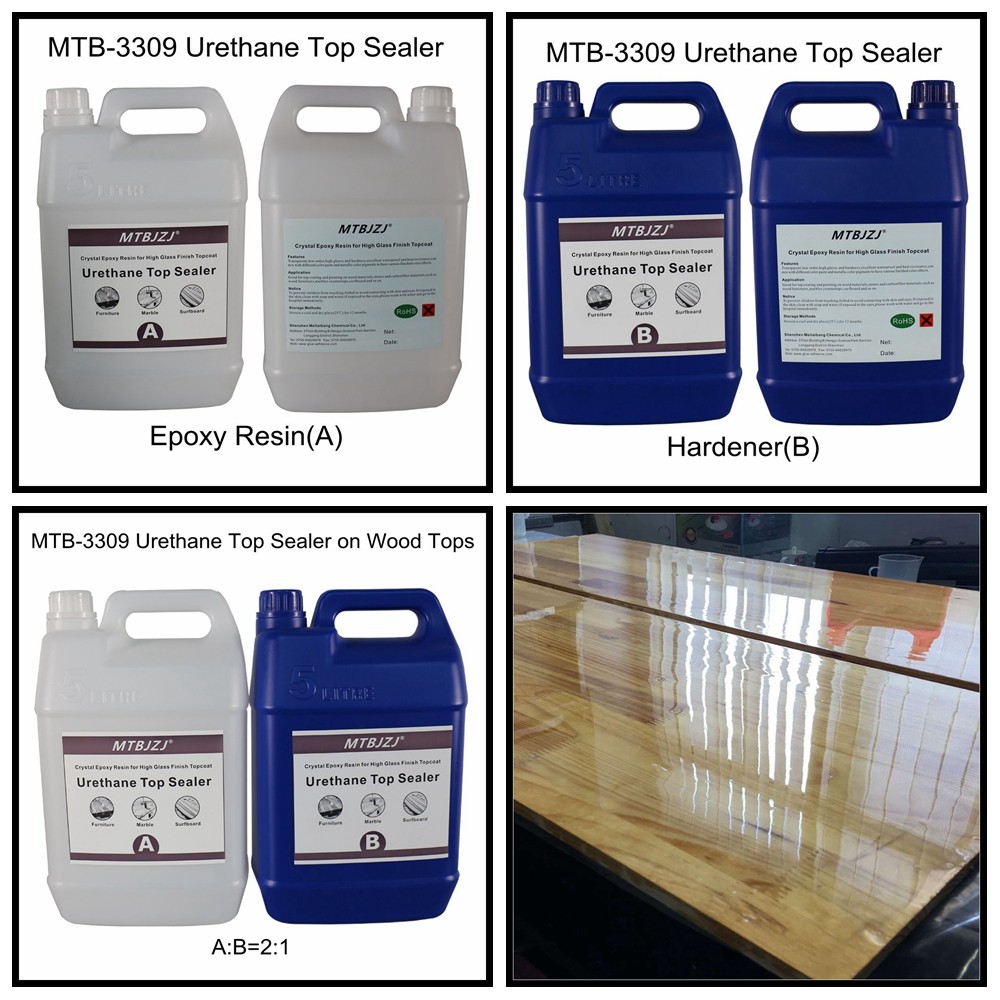

Instruction --Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.

Instruction --Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.

Typical Application

Technical Data Sheet

Technical Data Sheet

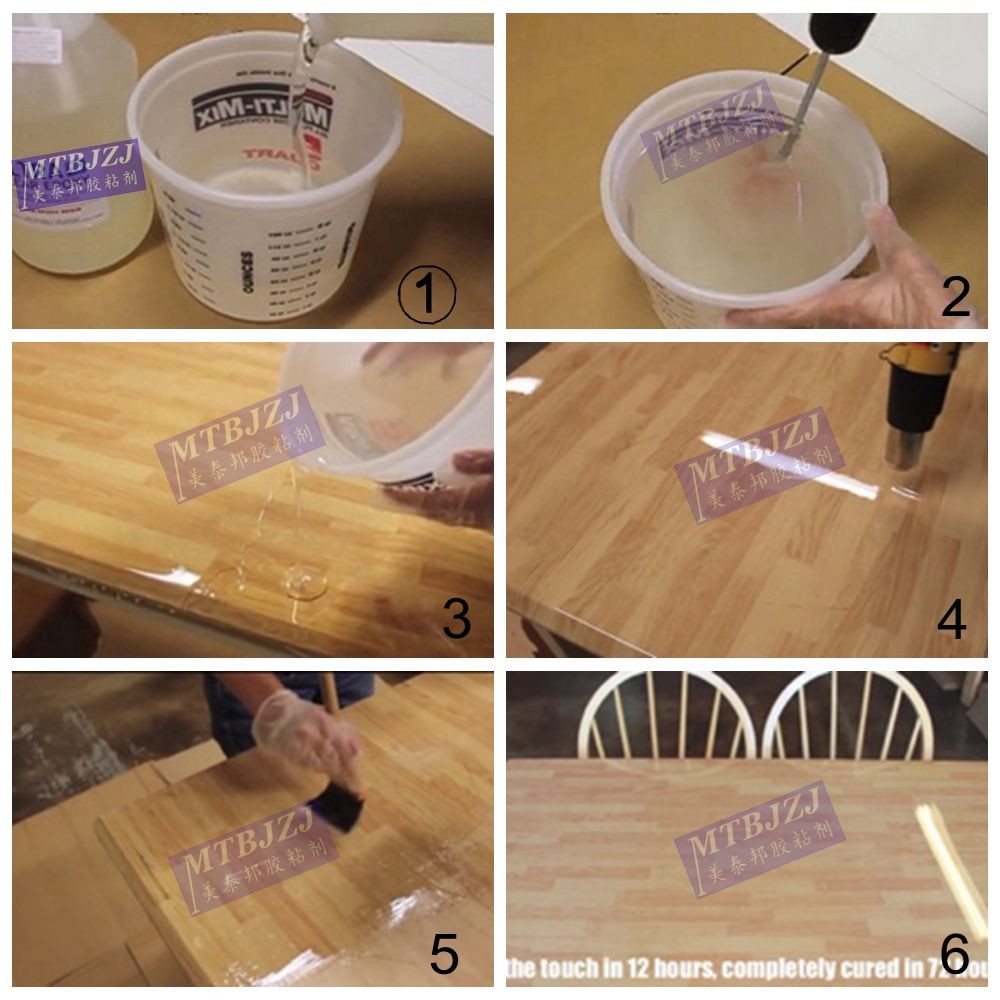

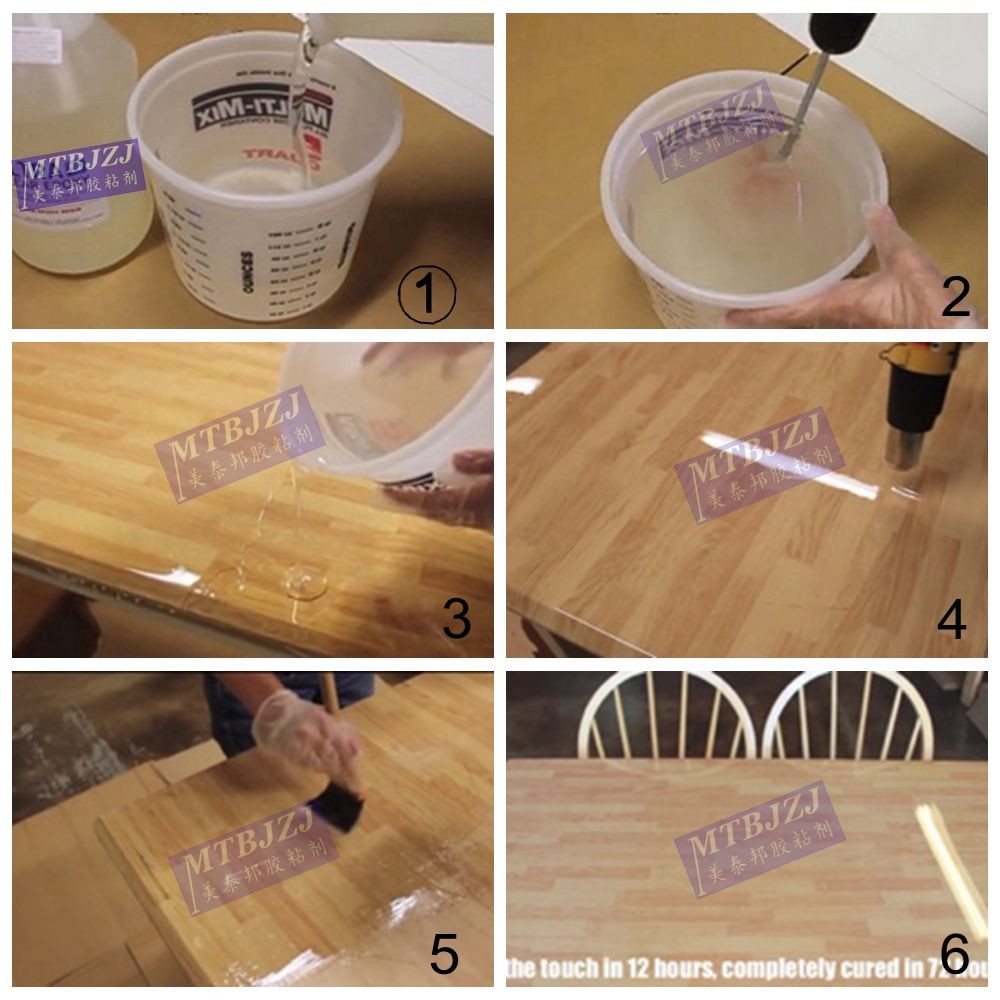

Using Steps  How to use MTB-3309 Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish? No experience needed.Get a beautiful crystal-clear surface in just a few easy steps.

How to use MTB-3309 Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish? No experience needed.Get a beautiful crystal-clear surface in just a few easy steps.

Step 1: Measure Epoxy

MTB-3309 Clear Epoxy is a two-part, epoxy coating that is mixed at a 2 to 1 ratio. Pour an equal amount of hardener and resin into a new container. It is important that you use a new container for each batch that you mix so that the next batch does not get contaminated from the remnants of curing epoxy in the previous container.

Step 2: Mix Epoxy

Mix thoroughly with our mixing drill bit to ensure that the batch is completely blended.

Step 3: Paint on a Seal Coat of Epoxy

On porous material such as wood, you will need to paint on a seal coat of the same epoxy first to seal any pores in the surface. This prevents air bubbles from forming in the following flood coat. Not all surfaces require a seal coat. Contact customer service if you are unsure if your project will need a seal coat as you will need to figure the seal coat into your epoxy order to make sure you have enough product.

Step 4: Pour Epoxy Flood Coat

Pour the epoxy onto the surface working your way down the length of the area. The epoxy self levels so there is no need to move it around with any tools. The epoxy coat can be allowed to flow over the sides which will create a coating on the vertical edges. The epoxy that drips over will form bumps about 1/2 inch underneath the lip of the edge. These drips can be sanded off once the epoxy has cured.

*Multiple flood coats can be applied to cover over embedded objects. Just pour a new flood coat every 4 hours.

Step 5: Pop Air Bubbles with a Plumber’s Torch or Heat Gun

Once you finish pouring the epoxy, you will need to pop air bubbles using a plumber’s torch or a heat gun (not a hair dryer). This process is the easiest step as it only takes about 30 seconds to 1 minute to do. Keep the torch or heat gun a few inches from the surface and simply wave it back and forth until you cover the entire distance of the surface. The heat pops any bubbles instantly.

Finished Project The epoxy is dry to the touch in 12 hours. Allow 72 hours before using the surface. That’s it!

Working Temperature of MTB-3309 Clear Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish

The working room temperature must be above 75 degrees, several hours prior to mixing the epoxy. We recommend that the product be brought inside and acclimated to room temperature, as it will be cold during winter shipping months. Use space heaters if necessary to ensure the temperature remains above 75 degrees in cold areas, such as garages and basements. It is extremely important that the temperature remain above 75 degrees for a full 72 hours, in order for the epoxy to cure. High or low humidity and higher temperatures (75-110 degrees) are perfectly fine for curing; the epoxy cures much faster with higher temperatures.

Coverage Data

Detailed Images

Packing & Delivery MTB-3309 Clear Table Top Epoxy Coating We have two types packages for you choice ---5kgs/barrel,15kgs/set ----20kgs/barrel,60kgs/set

Packing & Delivery MTB-3309 Clear Table Top Epoxy Coating We have two types packages for you choice ---5kgs/barrel,15kgs/set ----20kgs/barrel,60kgs/set

Delivery ---In common ,it takes about 1-3 days to prepare the cargoes for you after you confirm the order.The exact time depends on your quantity.

Our Service Why choose us ?

Our Service Why choose us ?

1. Professional manufacturer & long history

We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time .

2. Competitive quality &factory price

3. Our market

Our customer all over the world . Main market in Europe ,USA ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on .

We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time.

4. Custom design welcome

Customer logo /design/OEM welcome .So our products always so creative&innovative .

5. Best service

We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .

The most advanced epoxy coating on the market.

Ultra Clear epoxy boasts the most advanced level of shine, gloss, reflectivity, clarity and depth, and it locks in those optical qualities forever. The most sophisticated system of synthetic polymeric-based protection available. Our Commercial-grade epoxy is engineered specifically for Bar Tops, Tabletops & Countertops.

Instruction --Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.

Instruction --Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1.To make the finished top coat much more glossy and brighter.Typical Application

Technical Data Sheet

Technical Data Sheet  How to use MTB-3309 Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish? No experience needed.Get a beautiful crystal-clear surface in just a few easy steps.

How to use MTB-3309 Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish? No experience needed.Get a beautiful crystal-clear surface in just a few easy steps.Step 1: Measure Epoxy

MTB-3309 Clear Epoxy is a two-part, epoxy coating that is mixed at a 2 to 1 ratio. Pour an equal amount of hardener and resin into a new container. It is important that you use a new container for each batch that you mix so that the next batch does not get contaminated from the remnants of curing epoxy in the previous container.

Step 2: Mix Epoxy

Mix thoroughly with our mixing drill bit to ensure that the batch is completely blended.

Step 3: Paint on a Seal Coat of Epoxy

On porous material such as wood, you will need to paint on a seal coat of the same epoxy first to seal any pores in the surface. This prevents air bubbles from forming in the following flood coat. Not all surfaces require a seal coat. Contact customer service if you are unsure if your project will need a seal coat as you will need to figure the seal coat into your epoxy order to make sure you have enough product.

Step 4: Pour Epoxy Flood Coat

Pour the epoxy onto the surface working your way down the length of the area. The epoxy self levels so there is no need to move it around with any tools. The epoxy coat can be allowed to flow over the sides which will create a coating on the vertical edges. The epoxy that drips over will form bumps about 1/2 inch underneath the lip of the edge. These drips can be sanded off once the epoxy has cured.

*Multiple flood coats can be applied to cover over embedded objects. Just pour a new flood coat every 4 hours.

Step 5: Pop Air Bubbles with a Plumber’s Torch or Heat Gun

Once you finish pouring the epoxy, you will need to pop air bubbles using a plumber’s torch or a heat gun (not a hair dryer). This process is the easiest step as it only takes about 30 seconds to 1 minute to do. Keep the torch or heat gun a few inches from the surface and simply wave it back and forth until you cover the entire distance of the surface. The heat pops any bubbles instantly.

Finished Project The epoxy is dry to the touch in 12 hours. Allow 72 hours before using the surface. That’s it!

Working Temperature of MTB-3309 Clear Ultra Clear Table Top Epoxy Coating /Extremely Durable Table Top Finish

The working room temperature must be above 75 degrees, several hours prior to mixing the epoxy. We recommend that the product be brought inside and acclimated to room temperature, as it will be cold during winter shipping months. Use space heaters if necessary to ensure the temperature remains above 75 degrees in cold areas, such as garages and basements. It is extremely important that the temperature remain above 75 degrees for a full 72 hours, in order for the epoxy to cure. High or low humidity and higher temperatures (75-110 degrees) are perfectly fine for curing; the epoxy cures much faster with higher temperatures.

Coverage Data

Packing & Delivery MTB-3309 Clear Table Top Epoxy Coating We have two types packages for you choice ---5kgs/barrel,15kgs/set ----20kgs/barrel,60kgs/set

Packing & Delivery MTB-3309 Clear Table Top Epoxy Coating We have two types packages for you choice ---5kgs/barrel,15kgs/set ----20kgs/barrel,60kgs/set Delivery ---In common ,it takes about 1-3 days to prepare the cargoes for you after you confirm the order.The exact time depends on your quantity.

Our Service Why choose us ?

Our Service Why choose us ?1. Professional manufacturer & long history

We are direct manufacturer of glue and adhesive since 1998.So We have Professional production team, production line, experienced technical experts also much experiences and higher skills to ensuring product quality and deliver in time with a very short time .

2. Competitive quality &factory price

3. Our market

Our customer all over the world . Main market in Europe ,USA ,South America,Australia and Asia ,such as Vietnam,Thailand , Malaysia and so on .

We gained good reputation in the industry because our various items made of imported raw material, good workmanship and fast delivery time.

4. Custom design welcome

Customer logo /design/OEM welcome .So our products always so creative&innovative .

5. Best service

We keep every customer for long time business.We regard every one as our VIP,no matter small or big order .

Related Keywords

Related Keywords