3d glass printing machine large uv printer latest uv flatbed printer price

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

3d glass printing machine large uv printer latest uv flatbed printer price Product Description

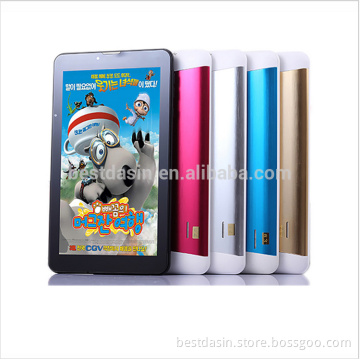

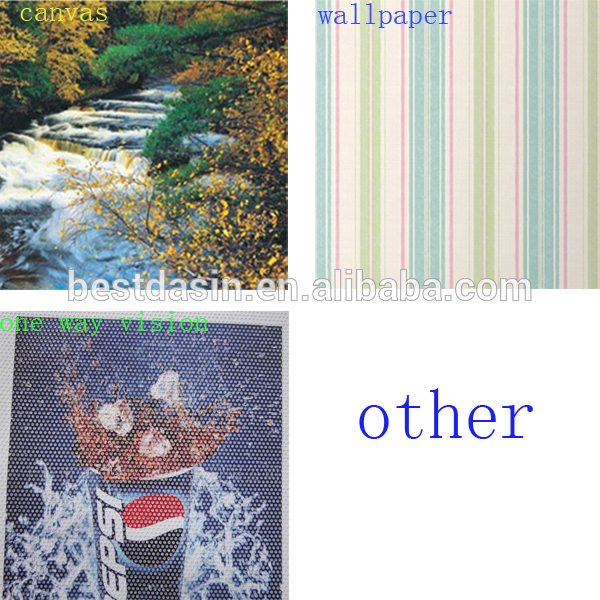

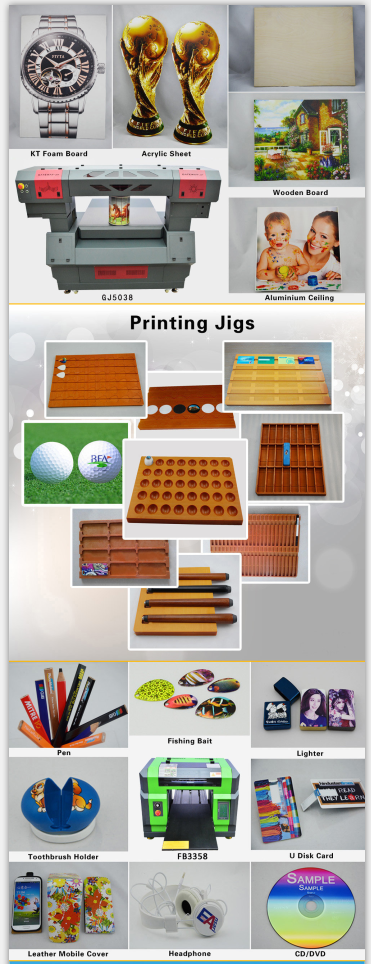

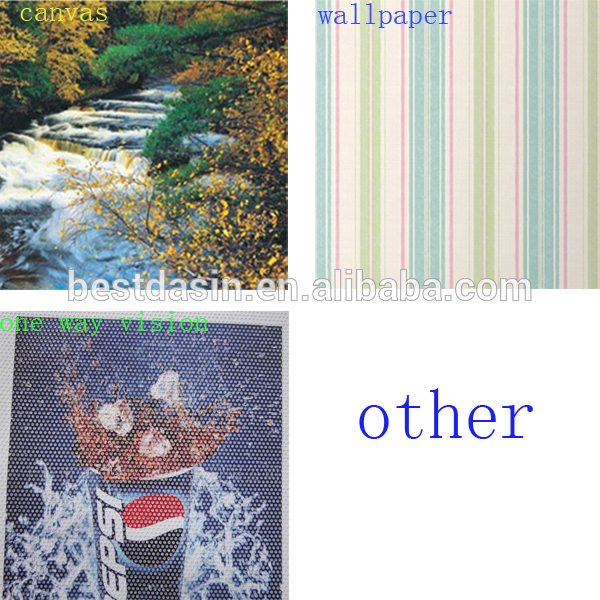

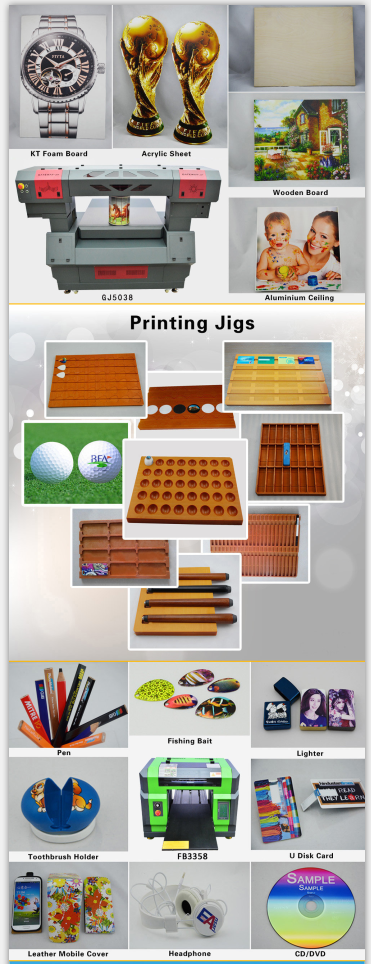

Application Samples

Company Information

Company Information

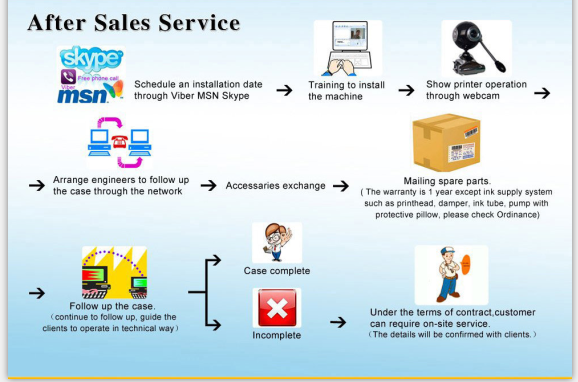

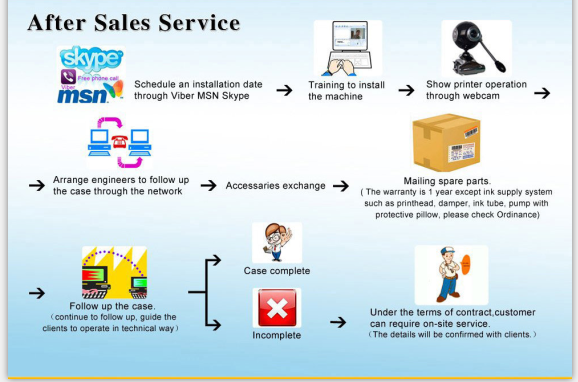

Our Services Excellent After-sale Services:

Our Services Excellent After-sale Services:

1.One year warranty

You can discuss operation and maintenance with our technician online support service by Skype, MSN etc. Remote control will be provided upon request.

2. Free exchange of new components

Our quality is guaranteed 100%, the spare parts can be replaced within one year free of charge includes the airfreight by express, except for the print head and some consumable parts.

3. Free online consultation

The technician will keep online. No matter what kind of technical questions that you may have, you would get a satisfactory answer from our professional technician easily.

4. Free onsite installation and training

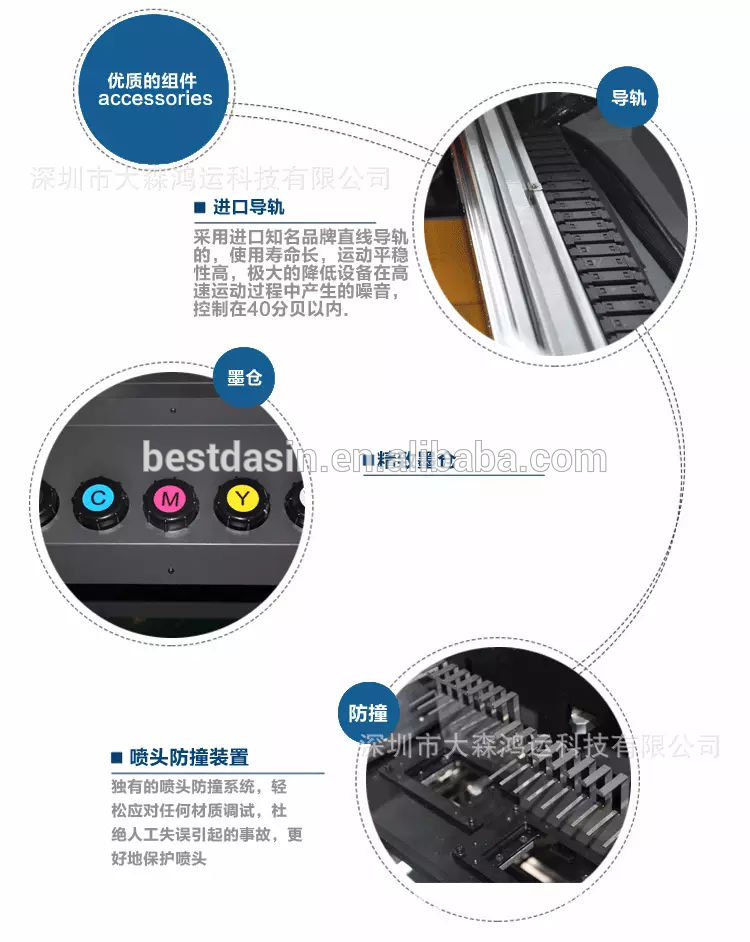

If you are able to help us with getting the visa and also would like to bear the costs involved like flight tickets, food, etc, we can send our technician to your office, and to give you a free installation and training for as long as you know how to operate it FAQ 1. What materials can print on ? POP board, KT board, Acrylic, organic glass etc. The UV printing reduce much work and trouble like lamination, fading, blistering, and save much working hours. Rigid signs board, hard carton or corrugated paper box, special market(like customize and decoration market): glasses, ceramic tiles, wood, even furniture. 2. production capacity / printing speed Single head uv printer is 60 sec. For A4 size, dual heads uv printer is 30 sec. For A4 size 3. How to move the machines UV printers belong to precise instrument, when you move them, please turn off all power, remove the cartridges and waste cartridge, keep other parts on the printer, and handle with care, keep shaking and heavy goods away from the printer. 4. How to make 3D embossed texture ? Can through two ways to reach 3D feeling: One is change media, by engrave to reach embossed feeling, then print by BESTDASIN printers, second is through BESTDASIN 3D printing technology, to accumulate UV ink to reach 3D effect. The 3D range will be bigger when use first ways; the second way have the height limit, and this way can re-print to reach more 3D effect, e.g. Mountain, use the second way can reach more Layering. 5. How to do when the status of the printhead is not good ? 5.1. Trun off power, move the printhead to the initial position, check if the printhead and cap top is in the same line 5.2. Do one time cleaning action, and print the test status. 5.3. If above operation still can’t solve this problem, then disassembly the printhead, cleaning the printhead manually or use cleaning machine to clean the printhead 5.4 If the status keep the same after above all operations, then check other parts or change a new printhead to test. 6. How to maintain the printer if couple of days no using the printer ? If the printer won’t use more than 3 days, you must cleaning out all ink in the printhead, otherwise, the ink will be dry because the solvent volatilization, even cause irreversible damage for the nozzles of the printhead. Below is the solving methods: Packaging & Shipping

Packaging & Shipping

| Model | large format printing machine DS 3398 |

| Printing size | 1300 * 2500 mm |

| Printing thickness | 15cm |

| Max resolution | 2880 dpiX1440dpi |

| Ink type | UV curing ink |

| Color number | CMYK WWWW / Dual CMYK |

| Printing interface | USB 3.0 high speed interface & 100 Base-T Ethernet interface |

| Printing Direction | Smart Bi-directional Printing Mode |

| Printing method | Drop on Demand (non-contact micro piezoelectric ink-jet printing technology) |

| Applicable industry | Rigid PVC board, glass, plastic, organic board, leather, rubber, special paper, metal, wood, porcelain, PVC, ABS, acrylic, aluminum, iron sheet, ceramic tile, glass, marble, granite, paperboard, etc |

| Printing method | Drop on Demand (non-contact micro piezoelectric ink-jet printing technology; micro piezoelectric printing technology; VSDT; intelligent nozzle clogging sensor system). 180nozzle/color*8; VSDT |

| Printing speed for A3 size | 720 dpi/ 20 second |

| 1440 dpi/ 45 second | |

| 2880 dpi/ 100 second | |

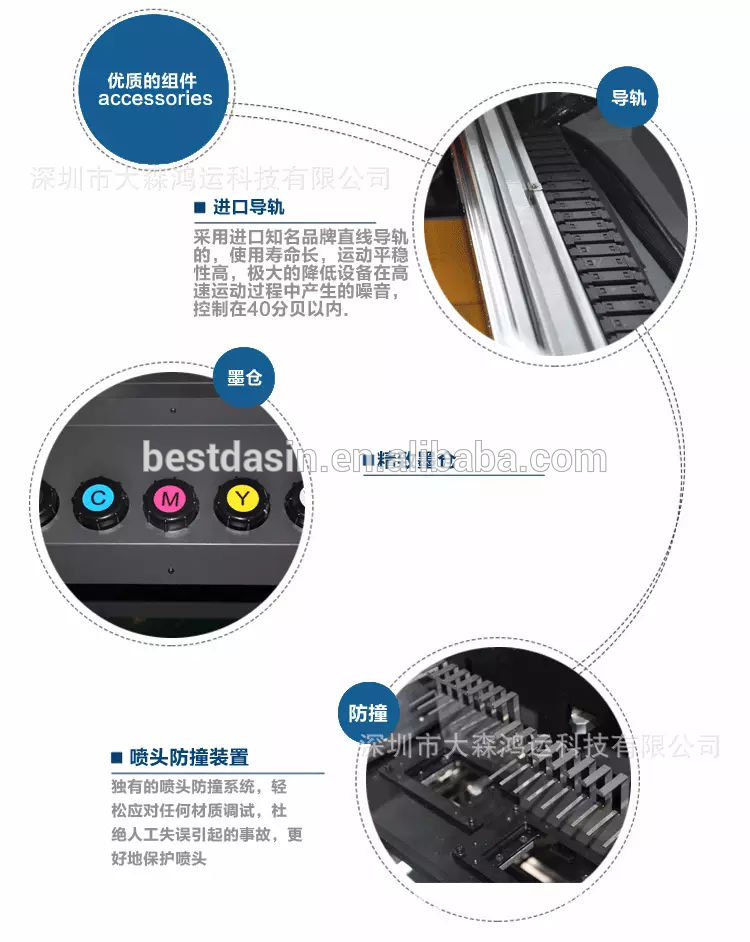

| Height detection of printing material | Infrared sensor |

| Ink consumption | 10 ML/SQM(square meter ) |

| Lamp type | LED Lamp (saving energy and environmental friendly) with shuttle ( non printing not lighting ) |

| Auto adjustment function | Nozzle automatic detection; print head automatic |

| machine size | 2370 mm * 1400 mm * 1300 mm |

| Height adjustment | Auto |

| Normal working environment | Temperature 10-35Celsius Humidity 20-80RH |

| Power/ Voltage | 95W / 220V/110V |

| Operation system | Windows 2008 / XP / WINS2007/ Vista, MAC,etc. |

| Machine configuration | USB line; driving software; power line; instruction book; washing and ink-joiner tools accessorry |

| Special remarks | Customized service is available. |

| DX5 Printhead |

| Instruction: DX5 DX7, Resolution: 2880DPI | |

| Color: 8 colors CMYK WWWW / Dual CMYK | |

| Print mode: 4, 6, 8, 12 Pass | |

| Notes: | |

A: The Operator need to make electrostatic?eliminating treatment and wear the Anti-static devices if possible to prevent the high static load from burning the circuit board inside of the print head. | |

| B: During installation, try not to touch the surface of print head directly. |

| Mainboard |

|

| Instruction: The mainboard and adapter board for controlling the printing of dual DX5 print heads | |

| Notes: | |

| A: Please connect the Ground Circuitry when installation | |

| B: Please turn off power first, then plug or pull out connector of wire |

| Screen panel |

| Introduction: Contain some control button, like control the movement of X axis, Y axis and Z axis | |

| Notes: | |

| A. Do not touch the surface with sharp items | |

| B. Please take care of the screen when operating |

| UV ink bottle |  |

| Item: UV ink bottle | |

| Introduction: 500ml UV ink bottle | |

| Notice: | |

| A.Avoid direct sunlight on the ink bottle | |

| B.Shake the ink bottle regularly to prevent ink sedimentation |

|

| DX5 headboard |

| Instruction: Printhead board | |

| Optical input | |

| Designed with individual adapter board for disassembling easily, reduce cost on repair,and more convenience on changing it | |

| Notes: | |

| A: Please connect the Ground Circuitry when installation | |

| B: Please turn off power first, then plug or pull out connector of wire |

Company Information

Company Information

Our Services Excellent After-sale Services:

Our Services Excellent After-sale Services:1.One year warranty

You can discuss operation and maintenance with our technician online support service by Skype, MSN etc. Remote control will be provided upon request.

2. Free exchange of new components

Our quality is guaranteed 100%, the spare parts can be replaced within one year free of charge includes the airfreight by express, except for the print head and some consumable parts.

3. Free online consultation

The technician will keep online. No matter what kind of technical questions that you may have, you would get a satisfactory answer from our professional technician easily.

4. Free onsite installation and training

If you are able to help us with getting the visa and also would like to bear the costs involved like flight tickets, food, etc, we can send our technician to your office, and to give you a free installation and training for as long as you know how to operate it FAQ 1. What materials can print on ? POP board, KT board, Acrylic, organic glass etc. The UV printing reduce much work and trouble like lamination, fading, blistering, and save much working hours. Rigid signs board, hard carton or corrugated paper box, special market(like customize and decoration market): glasses, ceramic tiles, wood, even furniture. 2. production capacity / printing speed Single head uv printer is 60 sec. For A4 size, dual heads uv printer is 30 sec. For A4 size 3. How to move the machines UV printers belong to precise instrument, when you move them, please turn off all power, remove the cartridges and waste cartridge, keep other parts on the printer, and handle with care, keep shaking and heavy goods away from the printer. 4. How to make 3D embossed texture ? Can through two ways to reach 3D feeling: One is change media, by engrave to reach embossed feeling, then print by BESTDASIN printers, second is through BESTDASIN 3D printing technology, to accumulate UV ink to reach 3D effect. The 3D range will be bigger when use first ways; the second way have the height limit, and this way can re-print to reach more 3D effect, e.g. Mountain, use the second way can reach more Layering. 5. How to do when the status of the printhead is not good ? 5.1. Trun off power, move the printhead to the initial position, check if the printhead and cap top is in the same line 5.2. Do one time cleaning action, and print the test status. 5.3. If above operation still can’t solve this problem, then disassembly the printhead, cleaning the printhead manually or use cleaning machine to clean the printhead 5.4 If the status keep the same after above all operations, then check other parts or change a new printhead to test. 6. How to maintain the printer if couple of days no using the printer ? If the printer won’t use more than 3 days, you must cleaning out all ink in the printhead, otherwise, the ink will be dry because the solvent volatilization, even cause irreversible damage for the nozzles of the printhead. Below is the solving methods:

Packaging & Shipping

Packaging & Shipping

Related Keywords

Related Keywords

You May Also Like

You May Also Like