Hardwall and softwall class 100 standards clean room

- Delivery Time:

- 10 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

Why Choose a Hardwall Cleanroom? Hardwall panels are a high-integrity modular cleanroom wall construction. Panels are mounted within robust steel frames to create un-breachable walls which enclose the clean area. This hardwall cleanroom construction is suitable for ultra-clean environments such as ISO class 5-8 clean zones, that require a higher level of control to achieve higher levels of cleanliness. The positive airflow pushes air down through the cleanroom, allowing particles to be flushed out evenly through the outlet at the bottom of the room. The clean finish the hardwalls give also makes them an attractive option for the lower classes of cleanroom, such as ISO 7-8, which softwall cleanrooms can also achieve. Benefits: Unbreachable, impact resistant & durable Gives a clean & easy-to-maintain finish Lets in light for ambient working conditions Choice of doors or softwall strips for entry Your logo can be printed on the panels Allow external staff to oversee the internal cleanroom processes

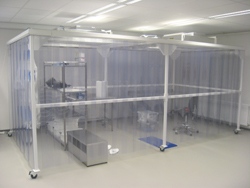

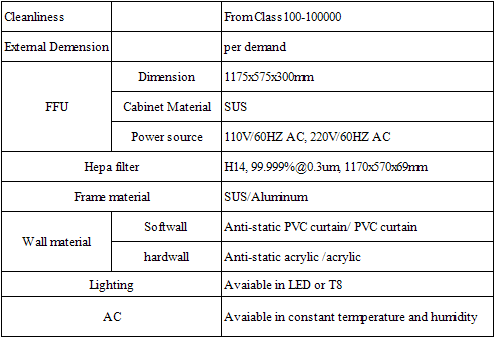

Why Choose a Hardwall Cleanroom? Hardwall panels are a high-integrity modular cleanroom wall construction. Panels are mounted within robust steel frames to create un-breachable walls which enclose the clean area. This hardwall cleanroom construction is suitable for ultra-clean environments such as ISO class 5-8 clean zones, that require a higher level of control to achieve higher levels of cleanliness. The positive airflow pushes air down through the cleanroom, allowing particles to be flushed out evenly through the outlet at the bottom of the room. The clean finish the hardwalls give also makes them an attractive option for the lower classes of cleanroom, such as ISO 7-8, which softwall cleanrooms can also achieve. Benefits: Unbreachable, impact resistant & durable Gives a clean & easy-to-maintain finish Lets in light for ambient working conditions Choice of doors or softwall strips for entry Your logo can be printed on the panels Allow external staff to oversee the internal cleanroom processes  Why Choose a Softwall Cleanroom? The PVC panels overlap to ensure the walls of the softwall cleanroom are effective barriers which won't breach, when in position, or allow particles to enter the room. The positive airflow pushes air down through the cleanroom, allowing particles to be flushed out through the outlet at the bottom of the room. Benefits: · Popular, economic option · Reduced static version optional · Non degradable in ambient conditions · High UV resistance ·Available in clear and many colour tints Detailed Images Overall Structure

Why Choose a Softwall Cleanroom? The PVC panels overlap to ensure the walls of the softwall cleanroom are effective barriers which won't breach, when in position, or allow particles to enter the room. The positive airflow pushes air down through the cleanroom, allowing particles to be flushed out through the outlet at the bottom of the room. Benefits: · Popular, economic option · Reduced static version optional · Non degradable in ambient conditions · High UV resistance ·Available in clear and many colour tints Detailed Images Overall Structure

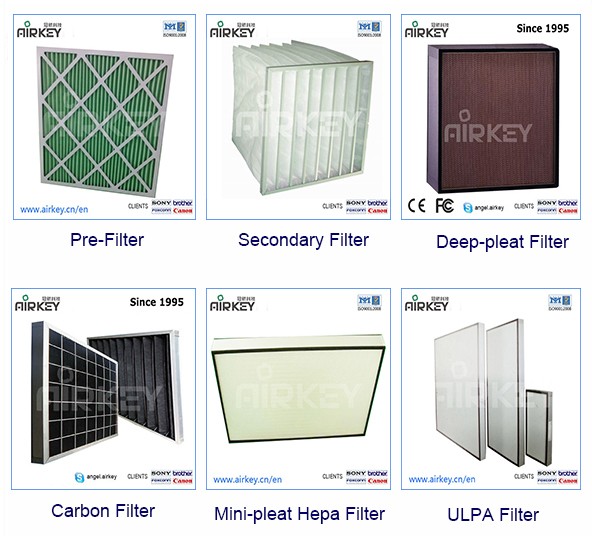

Separate Components | ||

| 1 |  | Air shower or goods air shower

Air shower is designed to remove dusts from staff or items before they enter into the clean room so as to prevent them from bringing pollution to the clean room. Our air shower can automatically start blowing by infrared sensor and the blowing is adjustable from 0-99s. |

| 2 |  | Fan Filter Unit (FFU)

FFUs are comprised of Hepa filters and fans. As the core of clean rooms, it is mainly used to clean the air and provide laminar flow for the clean room so as to maintain a highly clean area for production. It is easily assemblied and and filters in it can be conveniently replaced.

|

| 3 |  | Pass box

Pass box is used to pass small articles between clean and unclean areas. Through pass box to transfer small articles, there will be no need to open the door of the clean room, thus reducing pollution. Our pass box has bi-swing door with self-closing hinges to maintain room pressure |

| 4 |  | Clean bench

Clean bench provides laminar flow to keep a highly cleaned area for production, packing or other purposes. It maintains unidirectional downflow of airs to keep a specific area clean.

|

| 5 |  | |

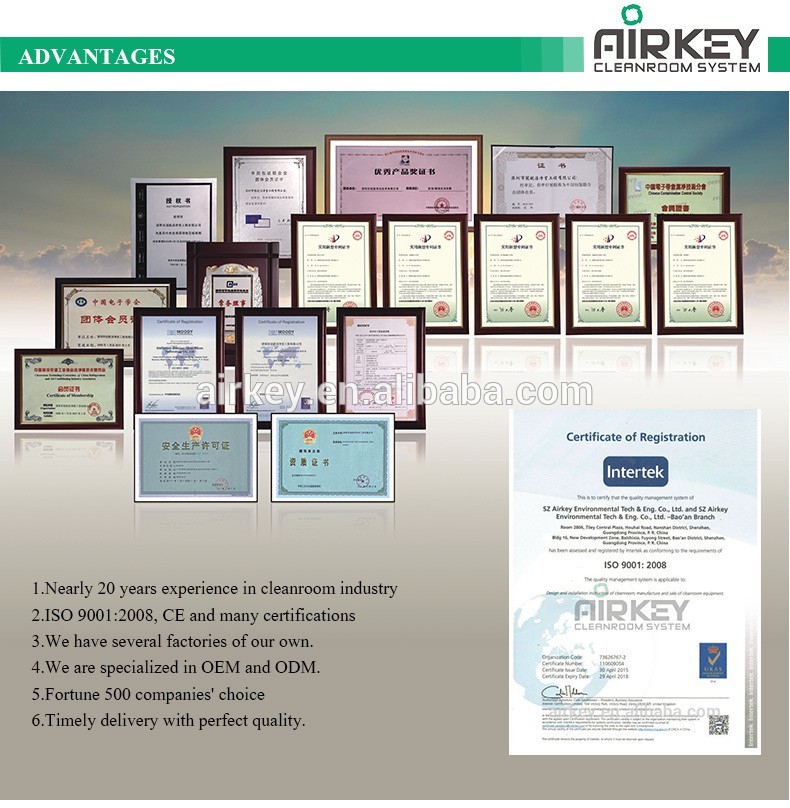

Company Profile Airkey's Value Advantages Facility Optimization ---Create the production environment you require without expense or discruption of major fab upgrade! Expand or reconfigure as your requirements change. Unsurpassed Cleanliness ---Filtation and ventilation efficiency required to meet the most rigorous cleanliness standards. Hardwall, Softwall and AirLock Design ---A style for every requirement, schedule and budget Comprehensive Environment Controls --Over particulates, humidity, temperature, and electrostatic discharge Industry leading Quality ---Over 20 years of engineering and manufacturing experience

Company Profile Airkey's Value Advantages Facility Optimization ---Create the production environment you require without expense or discruption of major fab upgrade! Expand or reconfigure as your requirements change. Unsurpassed Cleanliness ---Filtation and ventilation efficiency required to meet the most rigorous cleanliness standards. Hardwall, Softwall and AirLock Design ---A style for every requirement, schedule and budget Comprehensive Environment Controls --Over particulates, humidity, temperature, and electrostatic discharge Industry leading Quality ---Over 20 years of engineering and manufacturing experience

Certifications

Certifications

Related Keywords