High-speed CNC Engraving and Milling Machine for Medium-sized Injection Mold

- Delivery Time:

- 25 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Features ·X/Y/Z Axes are linear guide way,3 axes standard rapid feed 10m/min.24m/min is optional. · High precision,high rigidity machine body maintains the processing stability during high rotation speed. · Special reinforced spindle-case design,the cutting strength increased 20% in comparison with similar models. · Coulpling,spindle bearing,spindle,ball screw,and other key parts are imported from Germany,Japan and Taiwan top brand to ensure high quality and stability.

Product Features ·X/Y/Z Axes are linear guide way,3 axes standard rapid feed 10m/min.24m/min is optional. · High precision,high rigidity machine body maintains the processing stability during high rotation speed. · Special reinforced spindle-case design,the cutting strength increased 20% in comparison with similar models. · Coulpling,spindle bearing,spindle,ball screw,and other key parts are imported from Germany,Japan and Taiwan top brand to ensure high quality and stability. Model | Unit | CM860 | ||

| Processing Range | X Axis Travel | mm | 680 | |

Y axis Travel | mm | 760 | ||

Z axis Travel | mm | 330 | ||

Distance between spindle nose to worktable | mm | 50-380 | ||

Table | Table size | mm | 800*600 | |

Load weight | Kg | 400 | ||

T-Slot | Pcs-mm-mm | 5*18-115 | ||

Spindle | Holder size |

| ER25 | |

Diameter of Install | mm | Φ125 | ||

Spindle Rotary speed | r/min | 500-18000rpm | ||

Rated output torque | N.M | 4.5 | ||

Spindle motor power | kw | 5.5 | ||

Axis | X/Y/Z Axis motor rate output torque | N.M | 5.39 | |

Z Axis motor rated output torque | N.M | 22.5 | ||

X/Y/Z axis motor power | kw | 0.85 | ||

cutting feed speed | m/min | 8 | ||

Rapid speed of X/Y/Z axis | m/min | 10/10/10 | ||

Accuracy | X/Y/Z axis Positioning accuracy | mm | 0.005/0.005/0.005 | |

X/Y/Z axis Repeat positioning accuracy | mm | 0.005/0.005/0.003 | ||

Other | Dimension | mm | 2510*2337*2310 | |

Total Power | KVA | 10 | ||

Weight | Kg | 3500 | ||

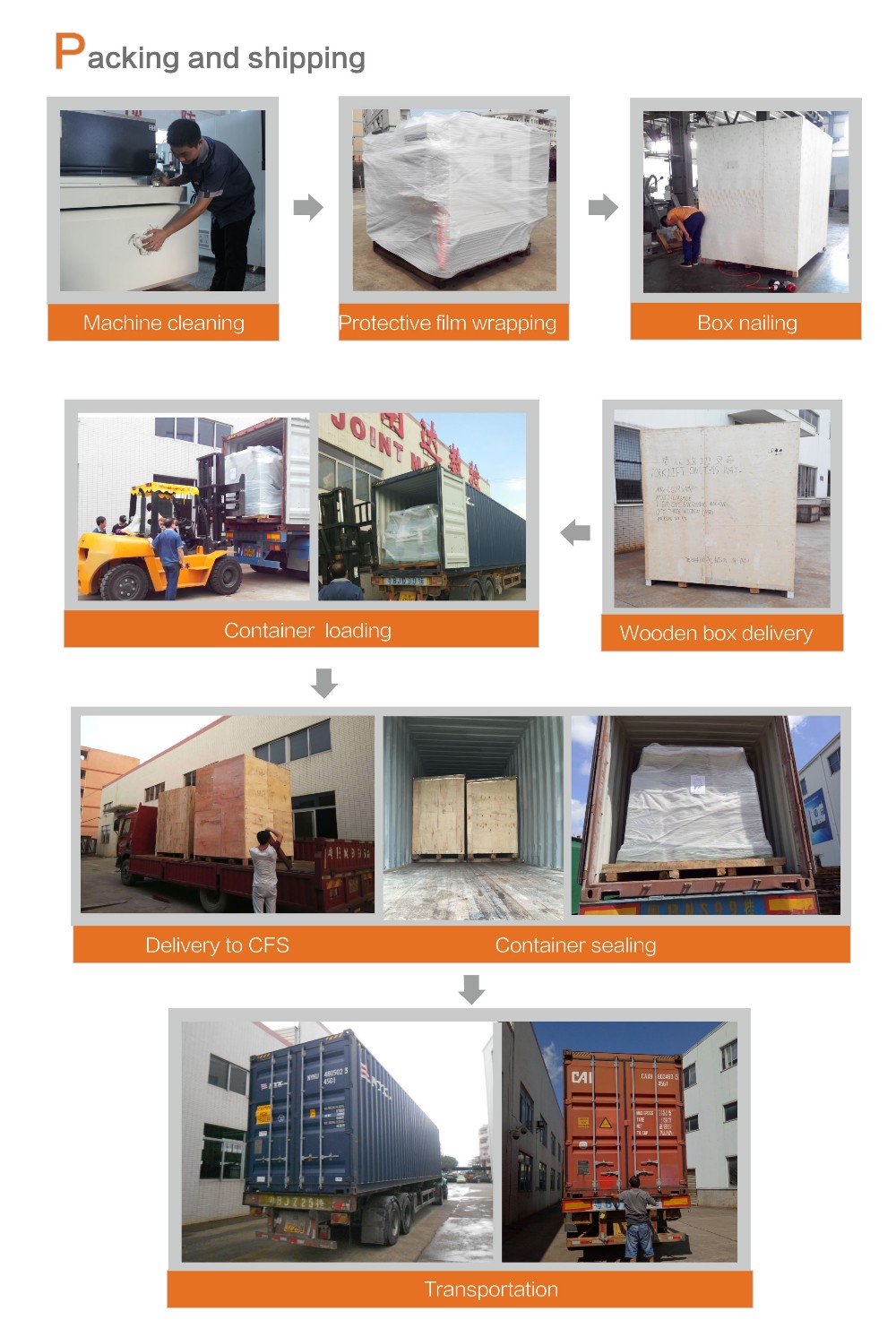

Our Services Special Advantage: We provide more fanctional and customized products. We provide CNC product application support. We provide integrated solutions for auto production line. We provide integrated design of molding and parts processing production line. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping

Our Services Special Advantage: We provide more fanctional and customized products. We provide CNC product application support. We provide integrated solutions for auto production line. We provide integrated design of molding and parts processing production line. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping  Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

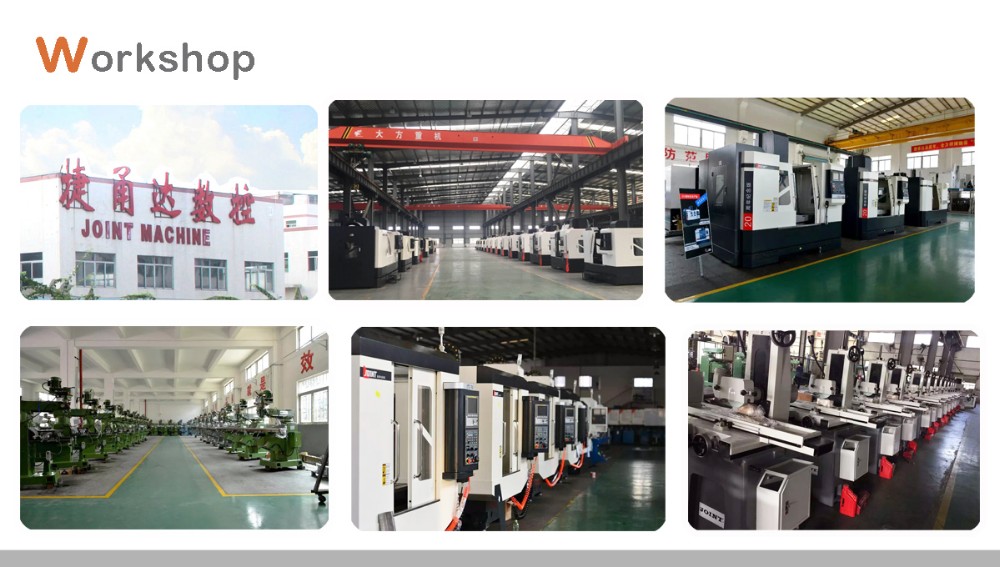

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America. Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Related Keywords