3 axis small CNC machine center VMC-650L

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

CNC Machine center VMC-650L Features: 1.Positioning accuracy 0.008mm/m;

2.Hardned & quenched slideway with Turcite B coated;

3.Imported ball screw;

4.Hardway type. 5.Hardened and quenched slideway with Turcite B coated makes the machine good anti-vibration performance,high rigidity and heavy loaded. 6.Spindle and spindle motor have been dynamic balanced,so tool life could be extended,and fantastic processing quality could be reached. 7.The design of whole cover is designing with good oil and water proof performance. 8.Taiwan famouse brand components(C3 leading screw,spindle and tool magazine). 9.Renishaw equipments are used to test each machine to meet the requirements of all clients. 10.Two dimensional and three dimensional trial cutting test of rigidity of tool magazine, to assure its high cutting quality. Specifications: Vertical Machine Center VMC650L

Accessories: 1.Standard accessoires: Control system Electronic hand wheel Cover Auto lubrication of slide way Coolant system Operation manual of machine Operation manual of control system Cutting fluid and filter system Stainless steel covers of slide way Alarming light Hammer balance Tool and toolbox 2.Optional accessories: Milling chuck and tool unlock Arm type or umbrella type tool magazine Auto chip conveyor Oil coolant The fourth axis NC dividing head or rotary table Heat exchanger

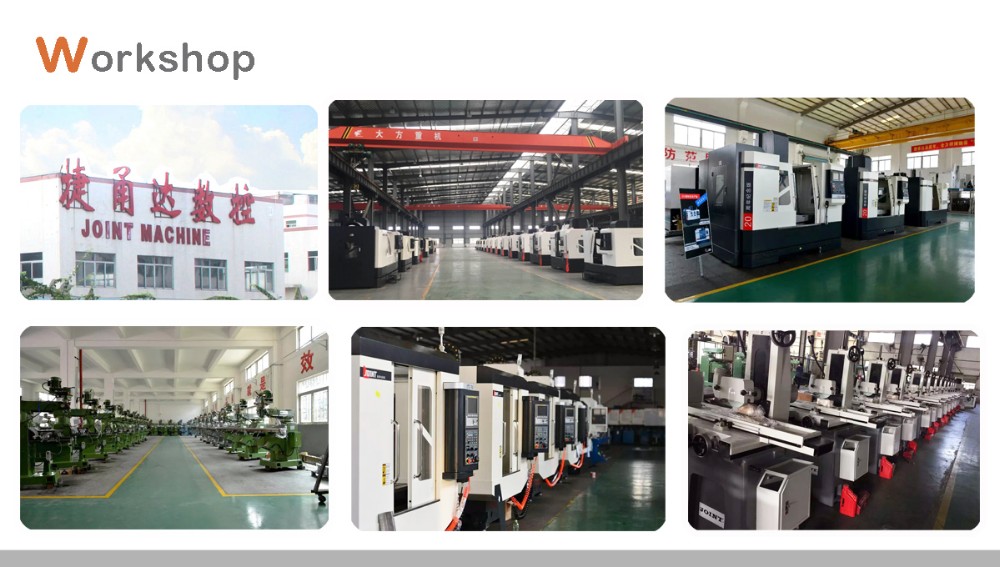

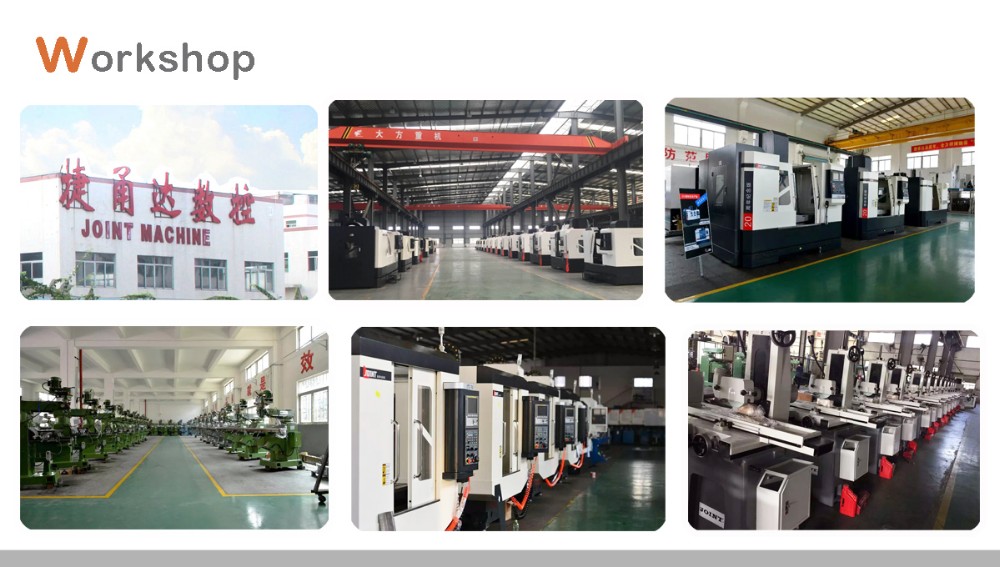

2.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field.

2.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field.  ]

]

2.Hardned & quenched slideway with Turcite B coated;

3.Imported ball screw;

4.Hardway type. 5.Hardened and quenched slideway with Turcite B coated makes the machine good anti-vibration performance,high rigidity and heavy loaded. 6.Spindle and spindle motor have been dynamic balanced,so tool life could be extended,and fantastic processing quality could be reached. 7.The design of whole cover is designing with good oil and water proof performance. 8.Taiwan famouse brand components(C3 leading screw,spindle and tool magazine). 9.Renishaw equipments are used to test each machine to meet the requirements of all clients. 10.Two dimensional and three dimensional trial cutting test of rigidity of tool magazine, to assure its high cutting quality. Specifications: Vertical Machine Center VMC650L

| Model | VMC650L |

| Table size | 800*500mm |

| Travel (Longitude (X)) | 600mm |

| Travel (Crossward (Y)) | 480mm |

| Travel (Vertical (Z)) | 500mm |

| Distance between spindle and table | 110-610mm |

| Distance between spindle and column | 560mm |

| Spindle (Rotation speed) | 8000/10000 |

| Spindle (Taper) | BT40 |

| Spindle (Motor) | 7.5kw |

| Rapid feed (Longitude(X)) | 24m/min |

| Rapid feed (Crossward(Y)) | 24m/min |

| Rapid feed (Vertical(Z)) | 12m/min |

| Cutting feed | 8m/min |

| Positioning accuracy | 0.008mm/m |

| Min enactment move unit | 0.001mm |

| Dimension(L*W*H) | 2760*2200*2700mm |

| Net weight | 5200kg |

| Max loaded of table | 350kg |

2.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field.

2.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field.  ]

]