The Most Popular /High speed parts processing CNC vertical machine center V85 with 3 aixs

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Features ◆ Specially designed for parts processing. 3 axes adopt ball guide way or roller linear guide way. Rapid feed speed 48 meters/min. ◆ Special Large span structure of the machine base and column, is able to bear high inertia gravity and improved dynamic responsiveness of the whole machine.

◆ Short nose design of Direct-Connection high speed spindle with excellent rigidity, increases efficiency and reduces abrasion of tools. Maximizes the transmission efficiency of spindle motor, and also increases processing accuracy and spindle durability.

◆ The machine employed backward chip removal with mass flow chip flushing system, suits particular parts processing for faster chip removing.

◆ Optional:spindle rotation speed, 12000/15000 rpm/min direct connection spindle, Spindle water coolant, Ring spray spindle, to accomodate different customer needs.

◆ Tool magazine adopts mechanical seal design and software warning to ensure reliable processing.

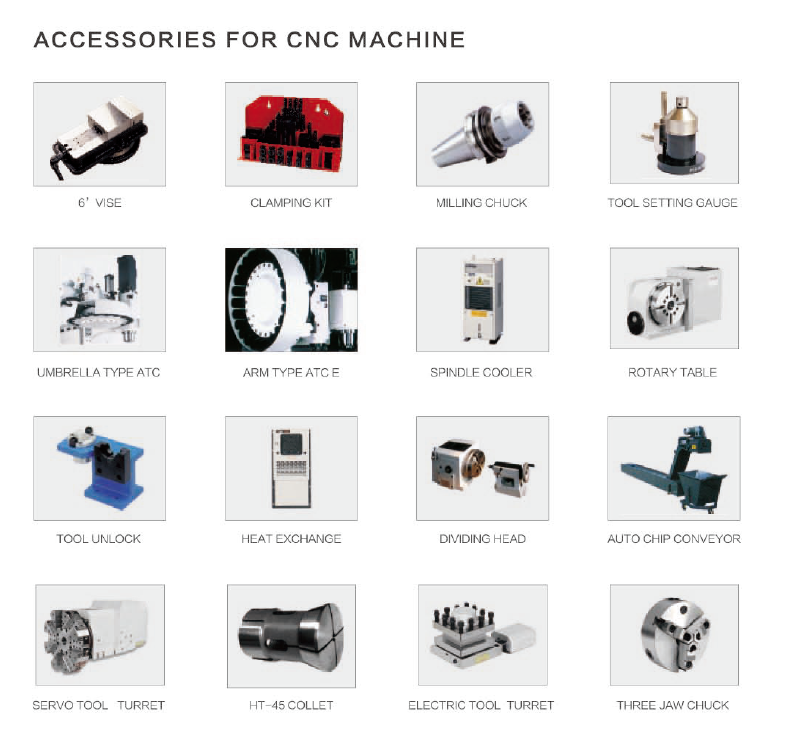

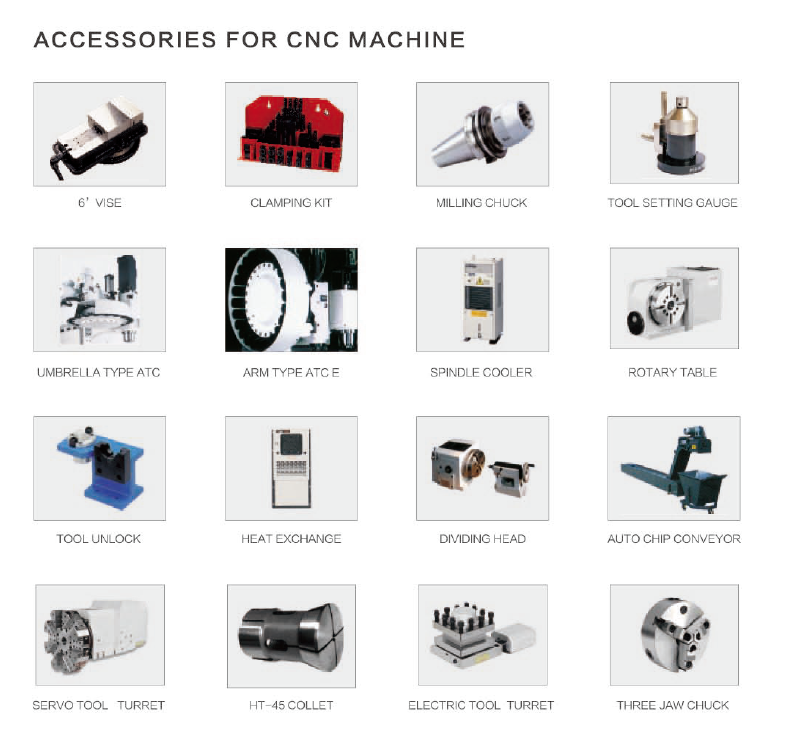

Acessories Standard Accessories Optional Accessories

◆ Spindle oil cooler ◆ Siemens Controller/ Other Controller

◆ Heat exchanger ◆ Screw type auto conveyor

◆ Full enclosed cover ◆ Chain type auto conveyor

◆ RS232 Interface ◆ 4 axis rotary table

◆ Working light ◆ Through spindle water coolant

◆ Tool and tool box ◆ Ring spray spindle

◆ Fanuc /Mitsubishi Controller system

◆ Spindle encoder feedback system

◆ Three lnner encoder feedback system

◆ Auto lubrication system

◆ Pneumatic system

◆ Operation unit

◆ Warming light

Our Service Warranty is a year, we would offer the parts( quality problem) free of charge during this period. Overseas service need to be charged extra.

Our Service Warranty is a year, we would offer the parts( quality problem) free of charge during this period. Overseas service need to be charged extra.  Our Company

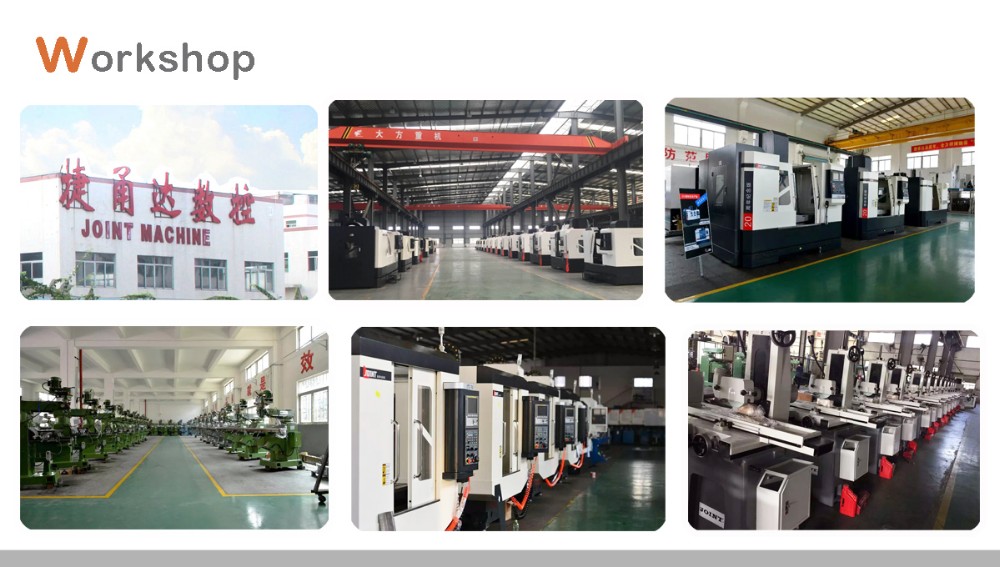

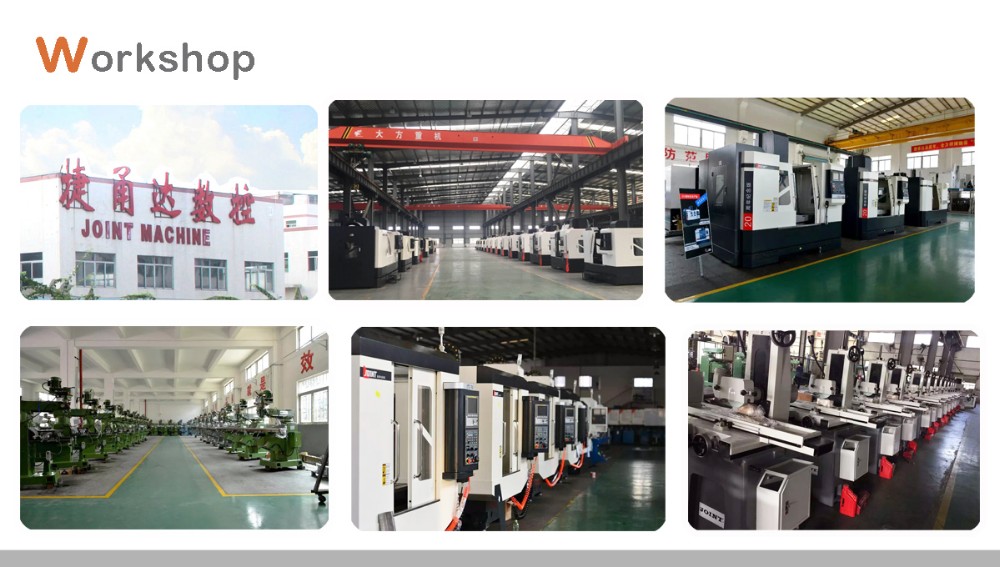

Our Company

Honors

Honors

Pictures

Pictures

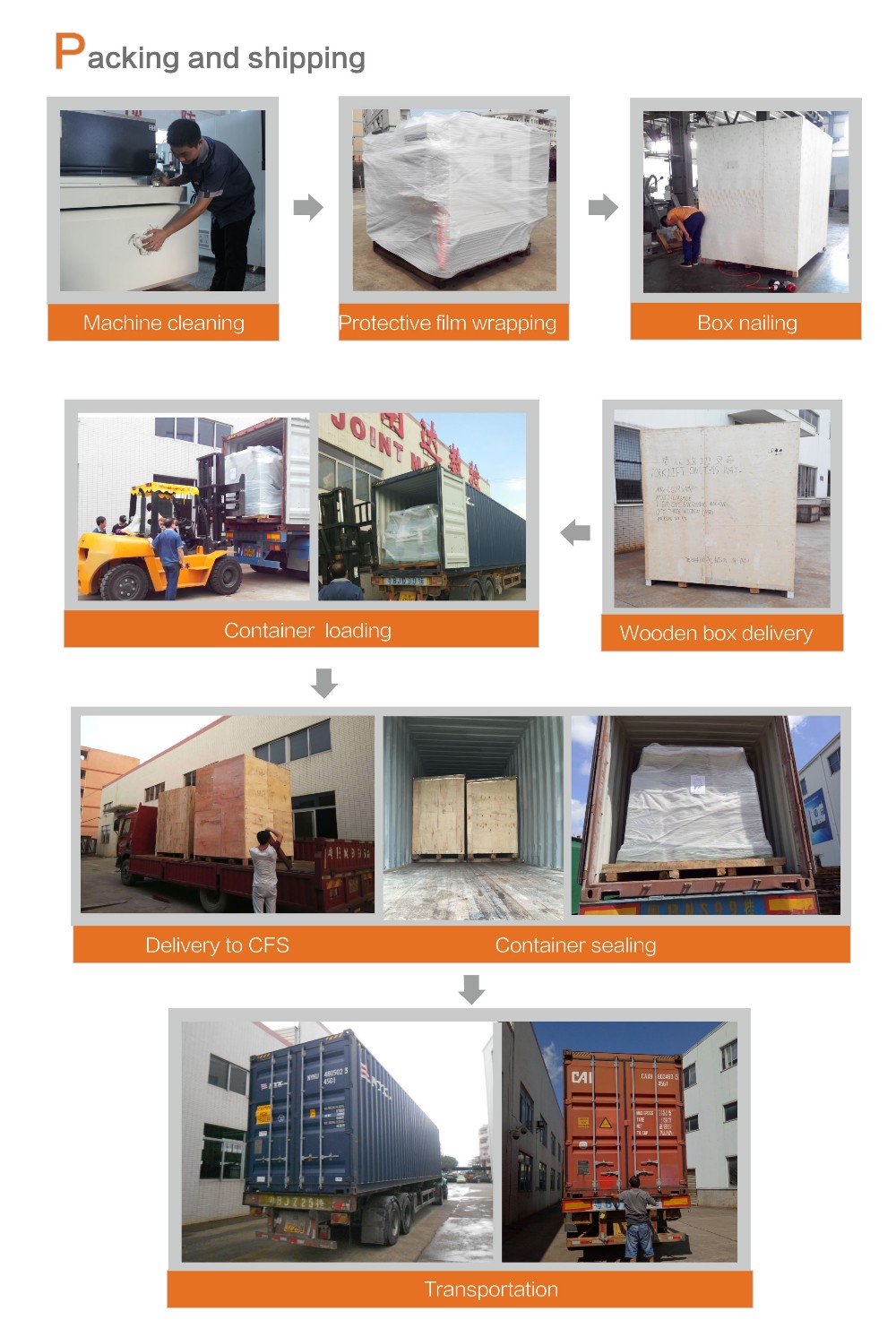

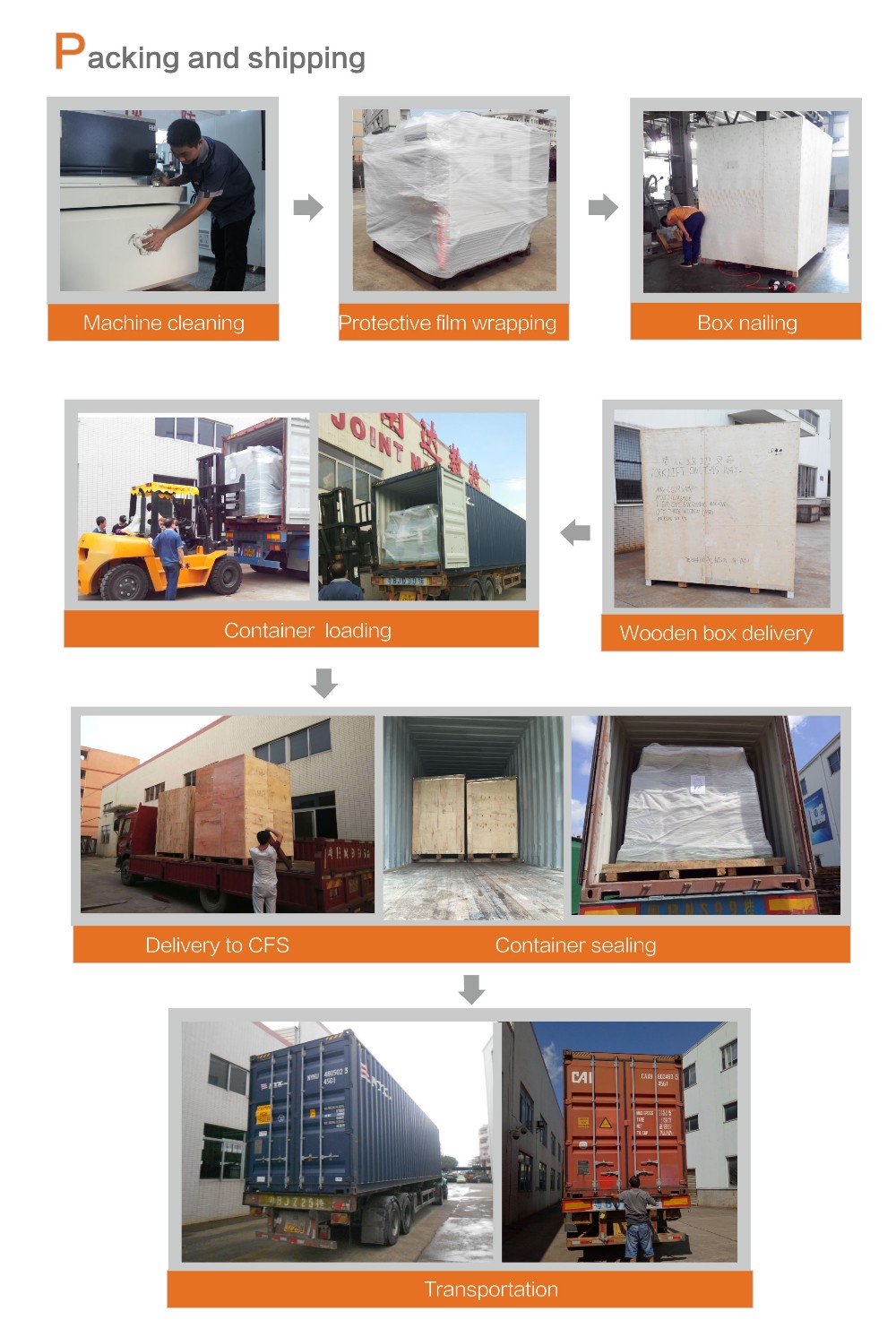

Package

Package  FAQ Q: Are you trading company or manufacturer ?

FAQ Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-15days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: 30% in advance.and the rest payment should pay before delivery.

Q: How many years have your company established?

A: 20 years, our company built in 1995.

◆ Short nose design of Direct-Connection high speed spindle with excellent rigidity, increases efficiency and reduces abrasion of tools. Maximizes the transmission efficiency of spindle motor, and also increases processing accuracy and spindle durability.

◆ The machine employed backward chip removal with mass flow chip flushing system, suits particular parts processing for faster chip removing.

◆ Optional:spindle rotation speed, 12000/15000 rpm/min direct connection spindle, Spindle water coolant, Ring spray spindle, to accomodate different customer needs.

◆ Tool magazine adopts mechanical seal design and software warning to ensure reliable processing.

◆ Spindle oil cooler ◆ Siemens Controller/ Other Controller

◆ Heat exchanger ◆ Screw type auto conveyor

◆ Full enclosed cover ◆ Chain type auto conveyor

◆ RS232 Interface ◆ 4 axis rotary table

◆ Working light ◆ Through spindle water coolant

◆ Tool and tool box ◆ Ring spray spindle

◆ Fanuc /Mitsubishi Controller system

◆ Spindle encoder feedback system

◆ Three lnner encoder feedback system

◆ Auto lubrication system

◆ Pneumatic system

◆ Operation unit

◆ Warming light

Our Service Warranty is a year, we would offer the parts( quality problem) free of charge during this period. Overseas service need to be charged extra.

Our Service Warranty is a year, we would offer the parts( quality problem) free of charge during this period. Overseas service need to be charged extra.  Our Company

Our Company

Honors

Honors

Pictures

Pictures

Package

Package  FAQ Q: Are you trading company or manufacturer ?

FAQ Q: Are you trading company or manufacturer ?A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-15days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: 30% in advance.and the rest payment should pay before delivery.

Q: How many years have your company established?

A: 20 years, our company built in 1995.

Related Keywords

Related Keywords