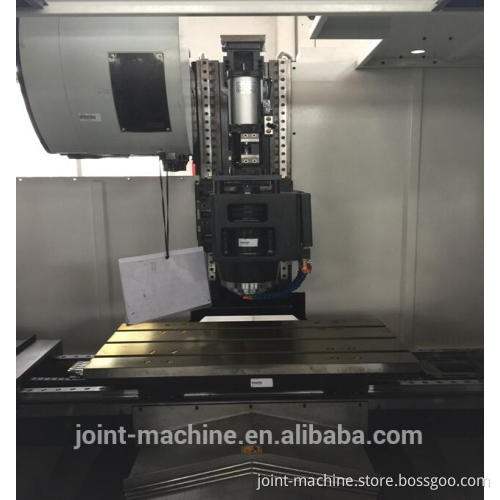

New Condition Vertical CNC Machining Center V85 With Strong Cutting Abalitty

- Delivery Time:

- 15 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

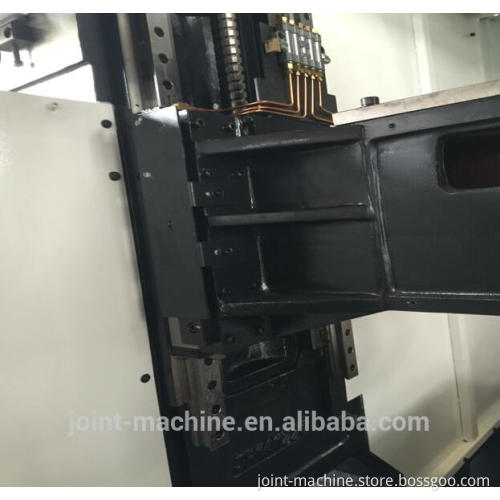

High Speed CNC Machine Center V85 Features (1) Specially designed for parts processing.3 axes adopt ball guide way or roller linear guide way.Rapid feed speed 48 meters/min. (2) Special large span structure of the machine base and column,is able to bear high inertia gravity and improved dynamic responsiveness of the whole machine. (3) The machine employed backward chip removal with mass flow chip flushing system,suits particular parts processing for faster chip removing. High Speed CNC Machine Center V85 Specifications

High Speed CNC Machine Center V85 Features (1) Specially designed for parts processing.3 axes adopt ball guide way or roller linear guide way.Rapid feed speed 48 meters/min. (2) Special large span structure of the machine base and column,is able to bear high inertia gravity and improved dynamic responsiveness of the whole machine. (3) The machine employed backward chip removal with mass flow chip flushing system,suits particular parts processing for faster chip removing. High Speed CNC Machine Center V85 Specifications Model | Unit | V85 | ||

| Processing Range | X Axis Travel | mm | 800 | |

Y axis Travel | mm | 500 | ||

Z axis Travel | mm | 500 | ||

Distance between spindle nose to worktable | mm | 170-670 | ||

Table | Table size | mm | 900*450 | |

Load weight | Kg | 500 | ||

T-Slot | Pcs-mm-mm | 3-18-130 | ||

Spindle | Holder size |

| BT40 | |

Diameter of Install | mm | Φ140 | ||

Rivet Size |

| BT40 45° | ||

Spindle Rotary speed | r/min | 10000RPM | ||

Rated output torque | Fanuc N.M | 35 | ||

Spindle motor power | Fanuc kw | 5.5~7.5 | ||

Axis | X/Y Axis motor rated output torque | Fanuc N.M | 13.7 | |

Z Axis motor rated output torque | Fanuc N.M | 22.5 | ||

X/Y axis motor power | Fanuc kw | 2.0 | ||

Z axis motor power | Fanuc kw | 3 | ||

cutting feed speed | mm/min | 15000 | ||

Rapid speed of X/Y/Z axis | m/min | 48/48/48 | ||

|

ATC | Capacity of tool | Tools | 24 |

Diameter /Length /Weight for Tool | mm/mm/kg | 80/200/8 | ||

Max Diameter of Tool | mm | 150 | ||

Choice tool ways |

| Optional | ||

Exchange tool time (tool-tool) | s | 2.5 | ||

Accuracy | X/Y/Z axis Positioning accuracy | mm | 0.006/0.006/0.006 | |

X/Y/Z axis Repeat positioning accuracy | mm | 0.005/0.005/0.005 | ||

Other | Dimension | mm | 2450*2180*2650 | |

Total Power | KVA | 15 | ||

Weight | Kg | 3800 | ||

Our Services

Our Services  Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research, development, manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research, development, manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

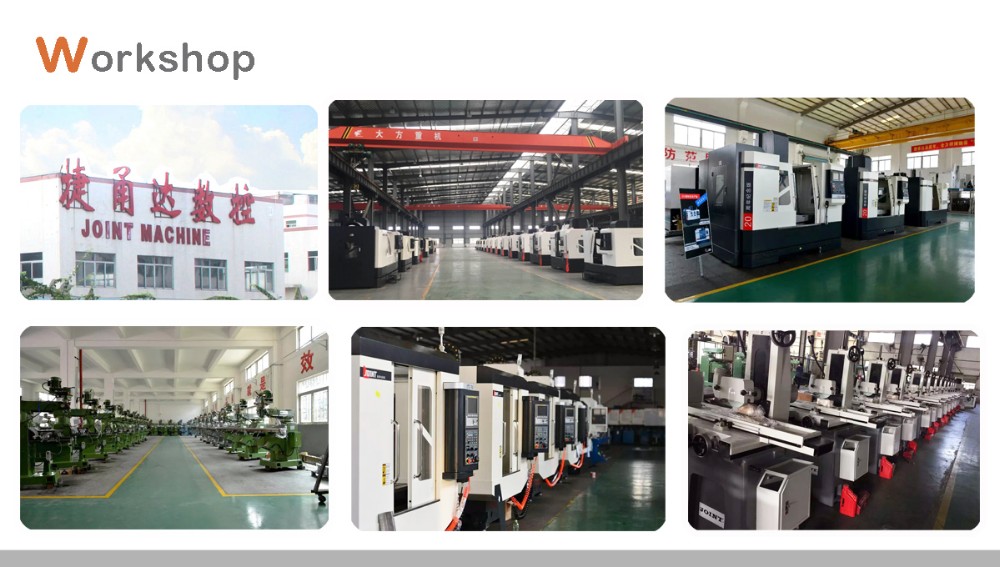

Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Quality Control

Quality Control  Certifications

Certifications

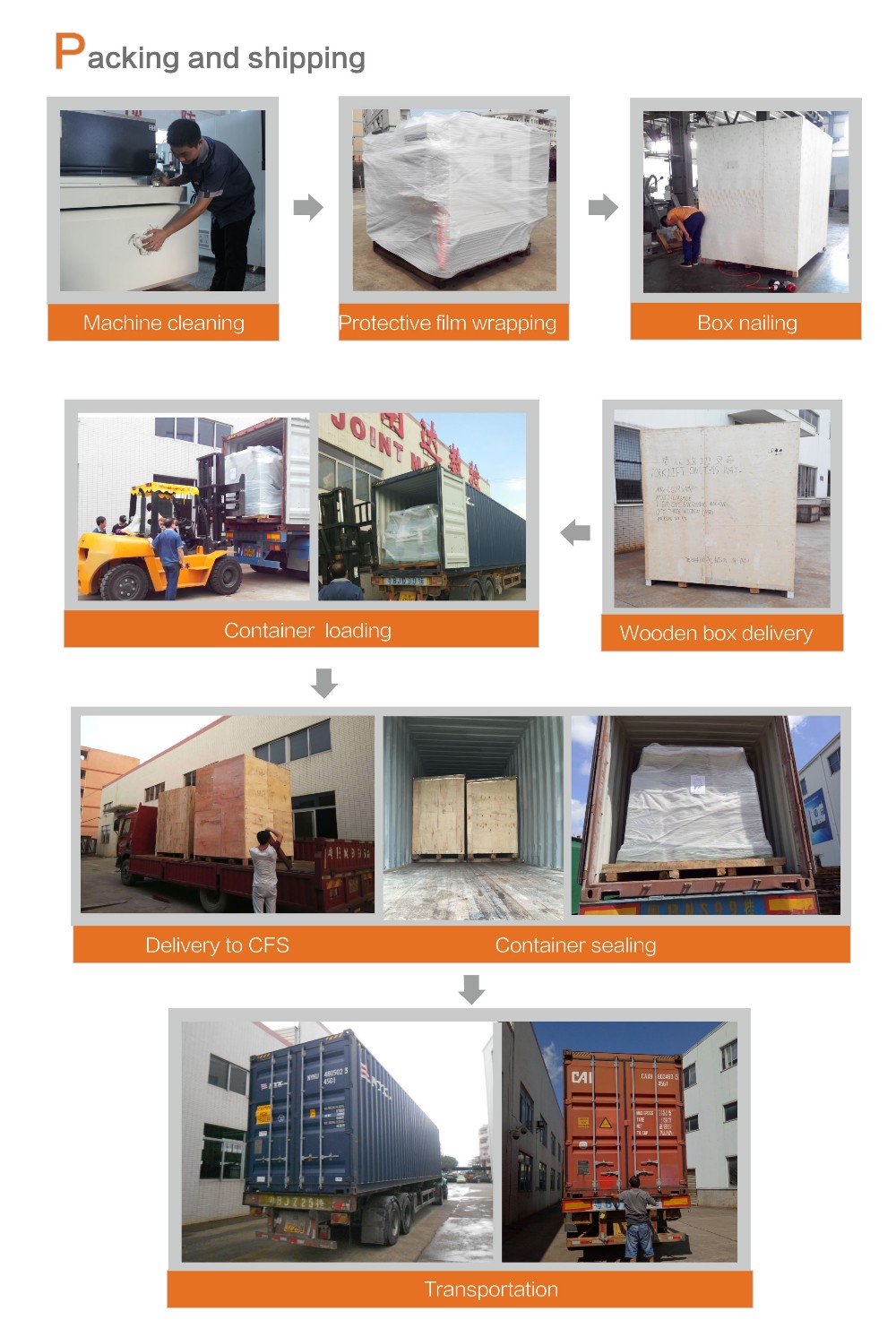

Packaging & Shipping

Packaging & Shipping  FAQ

FAQ Q: Are you a trade company of manufacturer? |

A: We are the original manufacturer over 20years. |

Q: How long is your delivery time? |

A: Generally, it’s 5-15days if the products in stock. If not, about 20-35days, according the quantity. |

Q: What are your terms of payment? |

A: 30% in advance, the rest payment should pay before delivery. |

Q: Do you provide OEM service? |

A: Of course we provide OEM and ODM service. |

Related Keywords