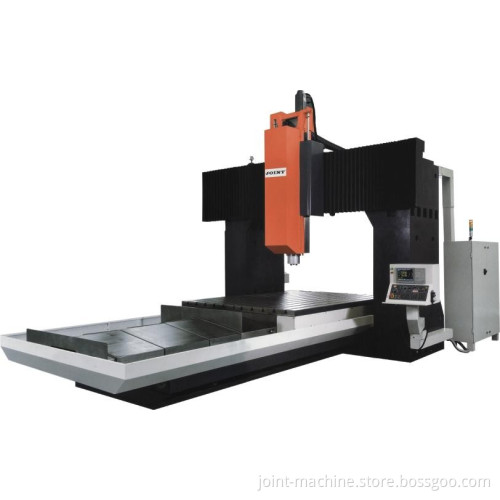

High quality gear head amd gantry type CNC machining center BTMC-1302

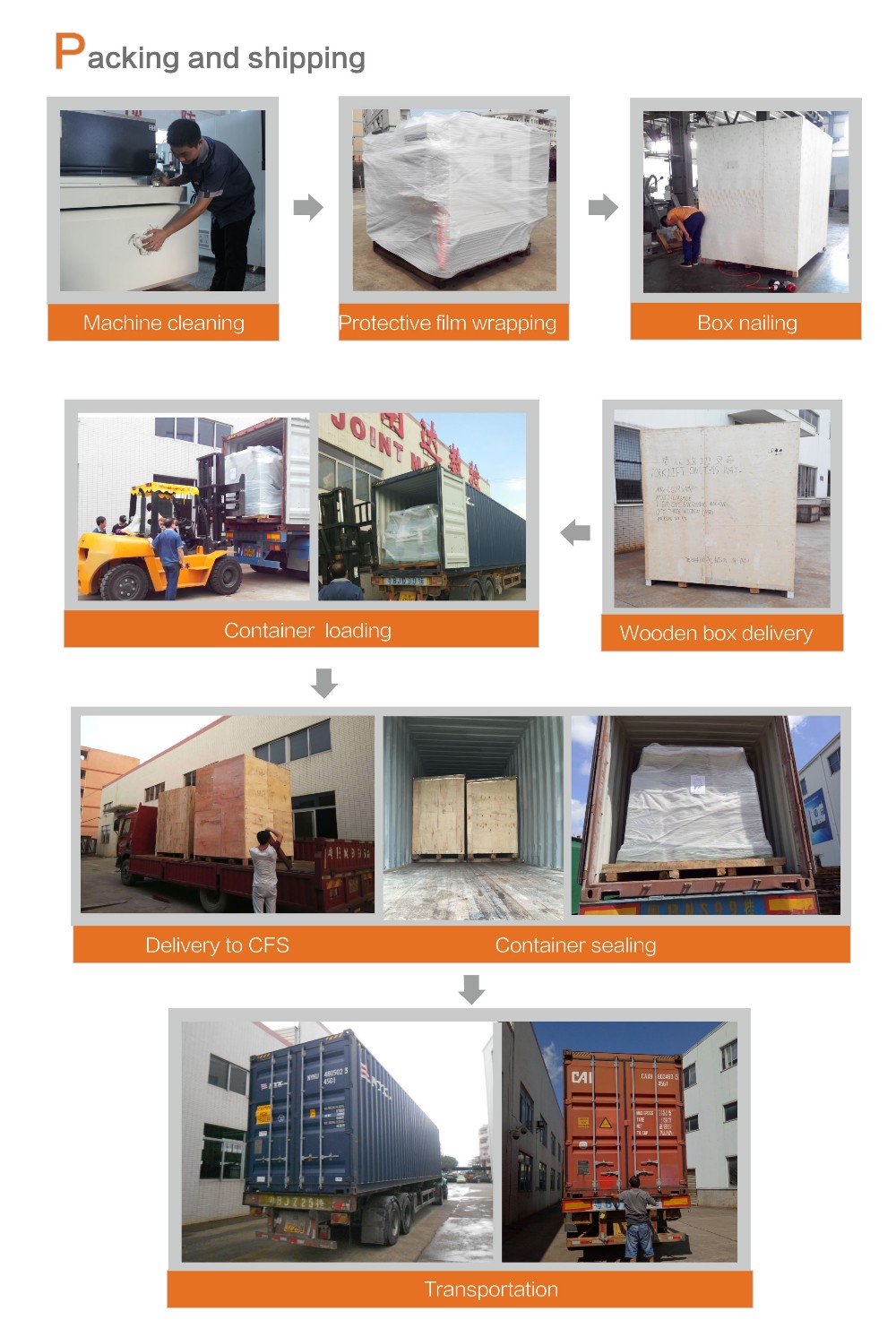

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Strengthened cutting with good quality Dragon-frame machining centerBTMC-1302 Specifications Fanuc /Mitsubishi/Siemens Control system

BT40 Spindle taper

7.5kw Spindle motor

12000rpm Spindle rotation speed 1, Fit for car mould ,engine mould and large screen and other large precise part processing . 2.Dragon frame type machine body, gear head is optional 3.Super high rigid pin roller linear way, embodies the heavy cut rigidity and rapid feed feature 4.Module design and serials products could meet with all kinds of requirement,

Accessories: 1.Standard accessoires: Control system Electronic hand wheel Cover Auto lubrication of slide way Coolant system Operation manual of machine Operation manual of control system Cutting fluid and filter system Stainless steel covers of slide way Alarming light Hammer balance Tool and toolbox 2.Optional accessories: Milling chuck and tool unlock Arm type or umbrella type tool magazine Auto chip conveyor Oil coolant The fourth axis NC dividing head or rotary table Heat exchanger  After-sales service : warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

After-sales service : warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty  1.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field

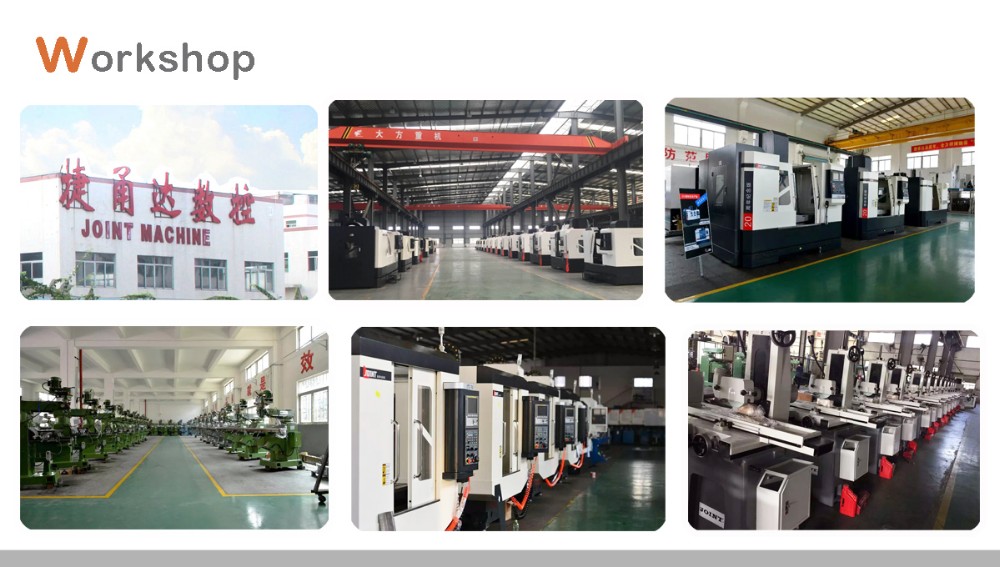

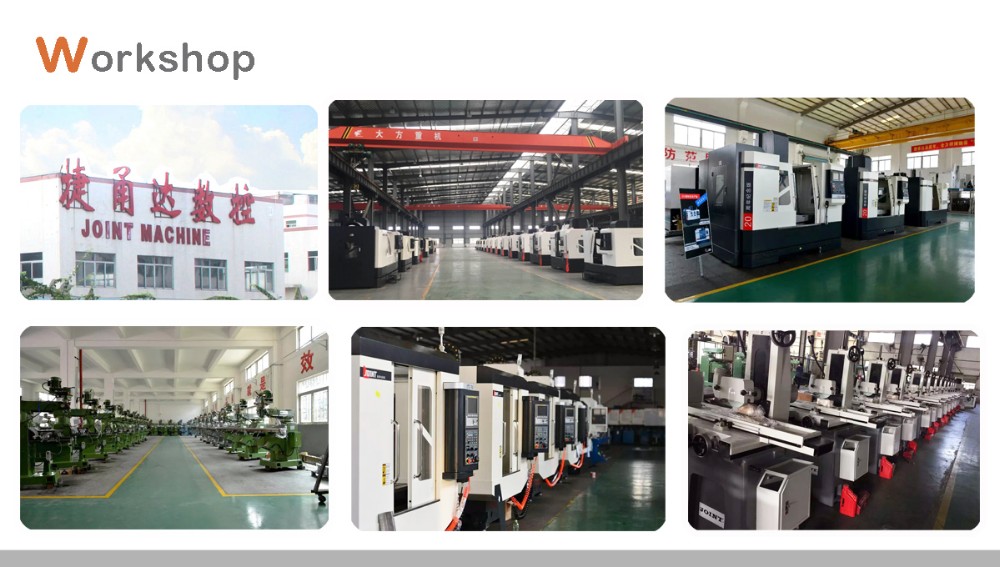

1.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field  2.Workshop: Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

2.Workshop: Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.  3.Certificate and Honour: 1.8 Intellectual property rights and 5 the patents 2.The self-owned brands of JOINT,NC-JYD have become the famous and high-quality mark in Chinese machinery field. 3.From 2004 to 2007,we have been granted with “Top 100 Metal Cutting Machine Tool Manufacturers” in China. 4.In 2011,we have been granted as” National Grade HI-Tech Enterprise”. 5.We have introduced ISO9001:2008 in 2009. 6.The turret Vertical milling machine,NC knee type milling machine and Vertical machine center and Surface grinding machine has obtained CE certificate notified by CCQS.

3.Certificate and Honour: 1.8 Intellectual property rights and 5 the patents 2.The self-owned brands of JOINT,NC-JYD have become the famous and high-quality mark in Chinese machinery field. 3.From 2004 to 2007,we have been granted with “Top 100 Metal Cutting Machine Tool Manufacturers” in China. 4.In 2011,we have been granted as” National Grade HI-Tech Enterprise”. 5.We have introduced ISO9001:2008 in 2009. 6.The turret Vertical milling machine,NC knee type milling machine and Vertical machine center and Surface grinding machine has obtained CE certificate notified by CCQS.

BT40 Spindle taper

7.5kw Spindle motor

12000rpm Spindle rotation speed 1, Fit for car mould ,engine mould and large screen and other large precise part processing . 2.Dragon frame type machine body, gear head is optional 3.Super high rigid pin roller linear way, embodies the heavy cut rigidity and rapid feed feature 4.Module design and serials products could meet with all kinds of requirement,

| Model | BTMC-1302 | BTMC-1502 | BTMC-2203 | BTMC-2204 | BTMC-2503 | BTMC-2505 |

| Table size | 2000*1000 | 2100*1200 | 3000*1800 | 4000*1800 | 3000*2000 | 5000*2300 |

| Longitude X travel | 2200 | 2000 | 3000 | 4000 | 3000 | 5000 |

| Crossward Y travel | 1300 | 1650 | 2200 | 2200 | 2700 | 2700 |

| Vertical Z travel | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

| Distance between spindle and table | 120-920 | 175*975 | 250-1250 | 250-1250 | 280-1280 | 260-1260 |

| Spindle rotation speed | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spindle Taper | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Spindle Motor | 15/18.5 | 22 | 22 | 22 | 30 | 30 |

| Rapid feed (X) | 12 | 12 | 12 | 12 | 12 | 12 |

| Rapid feed (Y) | 15 | 12 | 12 | 12 | 12 | 12 |

| Rapid feed (Z) | 15 | 12 | 12 | 12 | 12 | 12 |

| Cutting feed | 8 | 8 | 8 | 8 | 8 | 8 |

| Positioning accuracy | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Min set moving unit | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Dimension | 6500*3000*4000 | 7200*3700*4300 | 8700*4300*5100 | 10600*4300*5100 | 9200*5000*4800 | 13000*5000*4800 |

| Net weight | 15000 | 24000 | 36500 | 41500 | 43500 | 57000 |

| Max load of table | 3000 | 3000 | 6000 | 10000 | 10000 | 15000 |

| X axis travel of the other modles | 1325/2500 1303/3000 1335/3500 | 1503/3000 1504/4000 | 2202/2000 | 2205/5000 2206/6000 | 2504/4000 | 2506/6000 |

After-sales service : warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

After-sales service : warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty  1.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field

1.Research and Development team: We have a large group of Research and Development team , they own the professional theory knowledge, special technology skills and rich experience in the technical research field  2.Workshop: Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

2.Workshop: Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.  3.Certificate and Honour: 1.8 Intellectual property rights and 5 the patents 2.The self-owned brands of JOINT,NC-JYD have become the famous and high-quality mark in Chinese machinery field. 3.From 2004 to 2007,we have been granted with “Top 100 Metal Cutting Machine Tool Manufacturers” in China. 4.In 2011,we have been granted as” National Grade HI-Tech Enterprise”. 5.We have introduced ISO9001:2008 in 2009. 6.The turret Vertical milling machine,NC knee type milling machine and Vertical machine center and Surface grinding machine has obtained CE certificate notified by CCQS.

3.Certificate and Honour: 1.8 Intellectual property rights and 5 the patents 2.The self-owned brands of JOINT,NC-JYD have become the famous and high-quality mark in Chinese machinery field. 3.From 2004 to 2007,we have been granted with “Top 100 Metal Cutting Machine Tool Manufacturers” in China. 4.In 2011,we have been granted as” National Grade HI-Tech Enterprise”. 5.We have introduced ISO9001:2008 in 2009. 6.The turret Vertical milling machine,NC knee type milling machine and Vertical machine center and Surface grinding machine has obtained CE certificate notified by CCQS.

Related Keywords

Related Keywords

You May Also Like

You May Also Like