Double Column Mini Gantry Type CNC Machine Center BTMC-0812

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

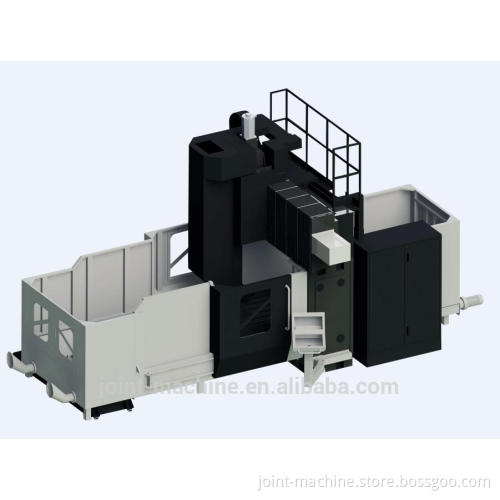

Product Description Double Column Mini Gantry Type CNC Machine Center BTMC-0812 Product Features Strengthened cutting ,best choice for large mould and part processing · High quality resin sand casted,gantry type frame structure,Z axis employs laminated slide way system,which suits high rigidity and high precision parts processing. · Adopts temperature control technique(our patent) to ensure stability and accuracy of long-hour processing. · Adopts modular design,which made many different type of optimized model.that satisfys the different customer processing needs and fast delivery requirements.

Product Features Strengthened cutting ,best choice for large mould and part processing · High quality resin sand casted,gantry type frame structure,Z axis employs laminated slide way system,which suits high rigidity and high precision parts processing. · Adopts temperature control technique(our patent) to ensure stability and accuracy of long-hour processing. · Adopts modular design,which made many different type of optimized model.that satisfys the different customer processing needs and fast delivery requirements.

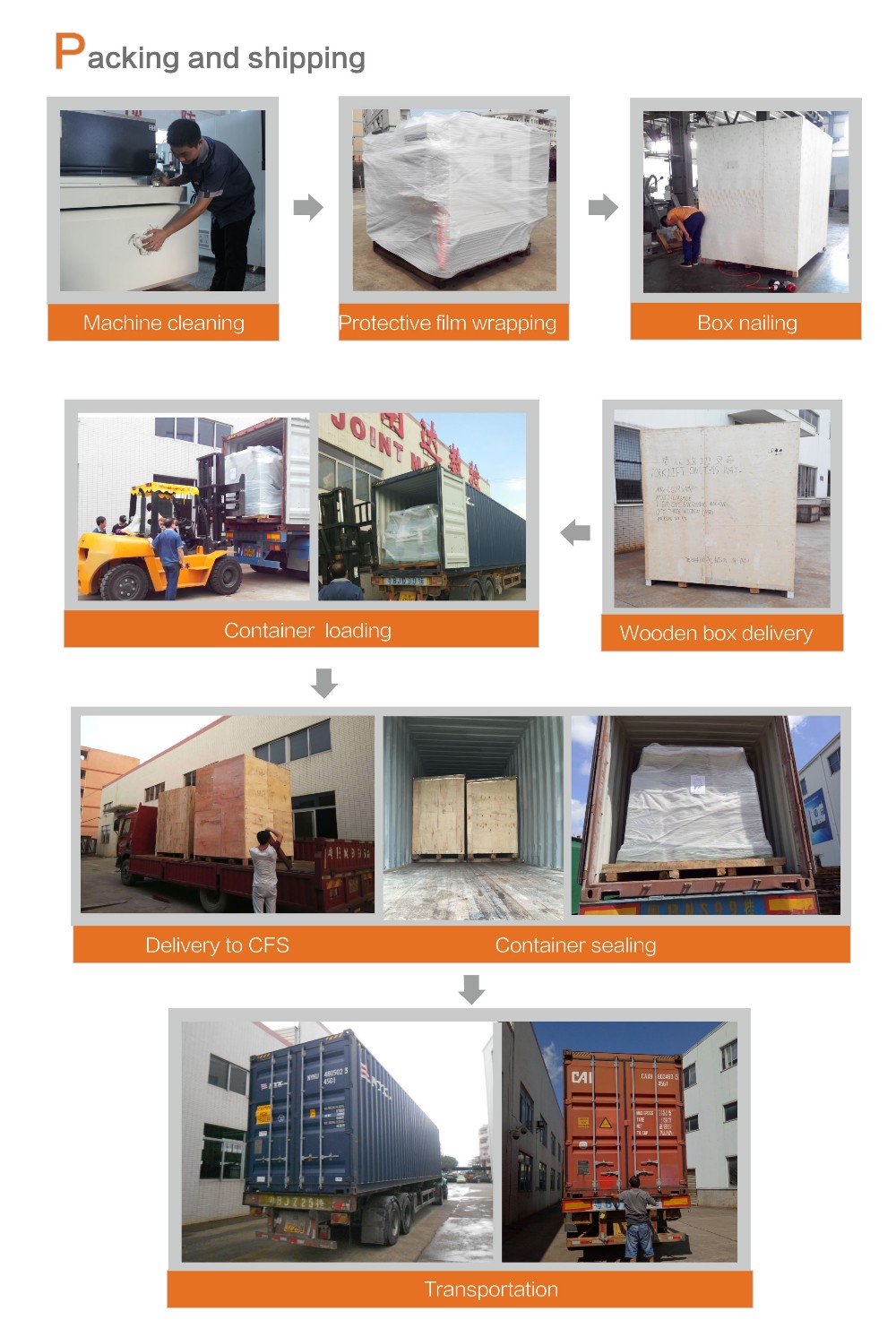

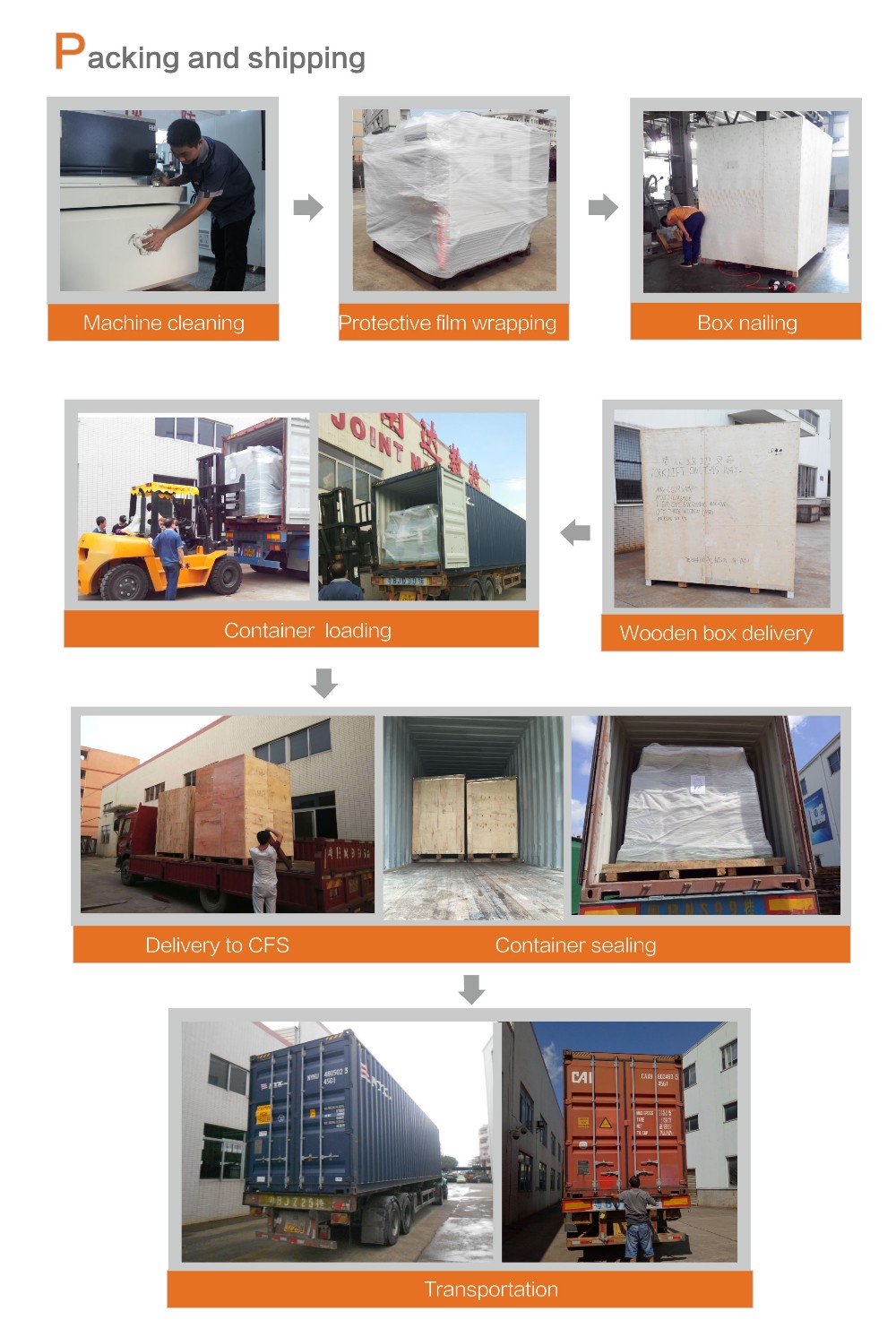

Accessories 1.Standard accessoires: 2.Optional accessories: · Spindle oil cooler · Other Controllers · Heat exchanger · 4 axis rotary table · Auto conveyor · Through Spindle water coolant · Full enclosed cover · Ring spray spindle · Auto lubrication system · ZF gear box · Pneumatic system · 90 degree angle milling head · RS232 Interface · Operation unit · Warming light · Workling light · Tool and tool box · Spindle encoder position system · Three Inner encoder feedback system · Fanuc/Mitsubishi Controller system Our Services  Packaging & Shipping

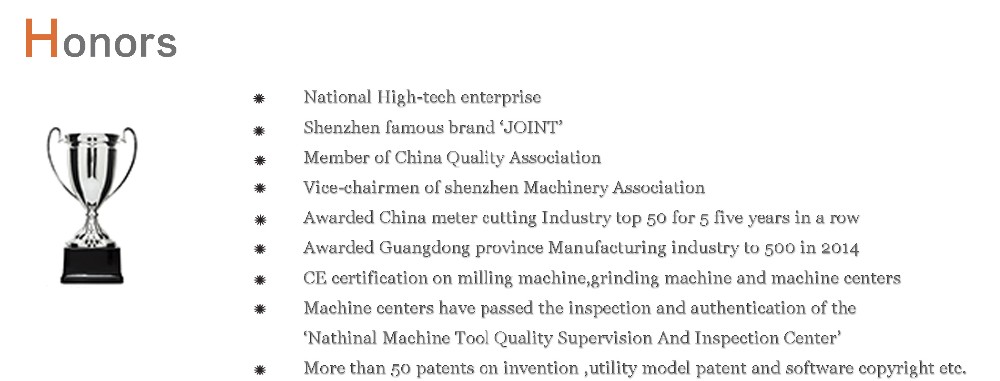

Packaging & Shipping  Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

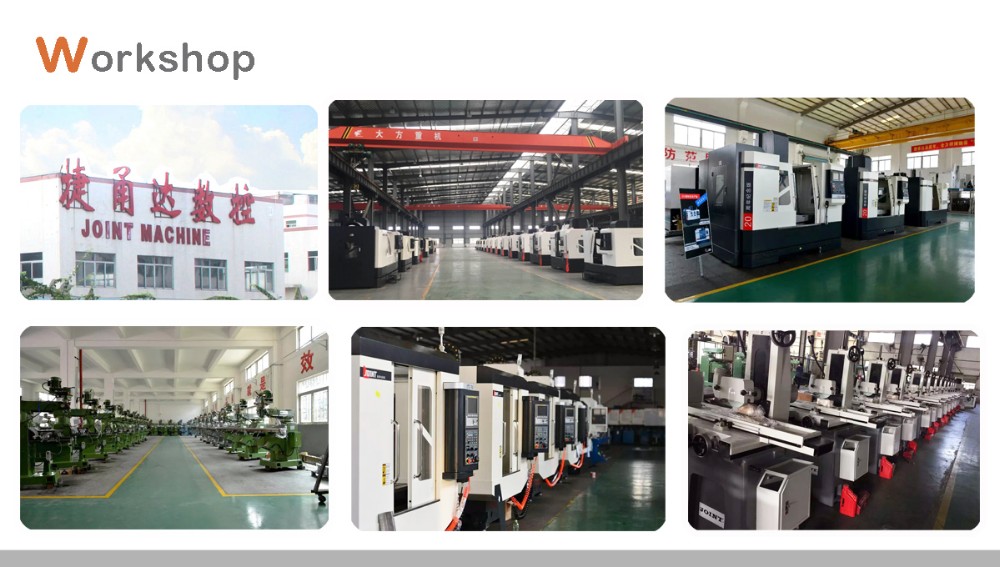

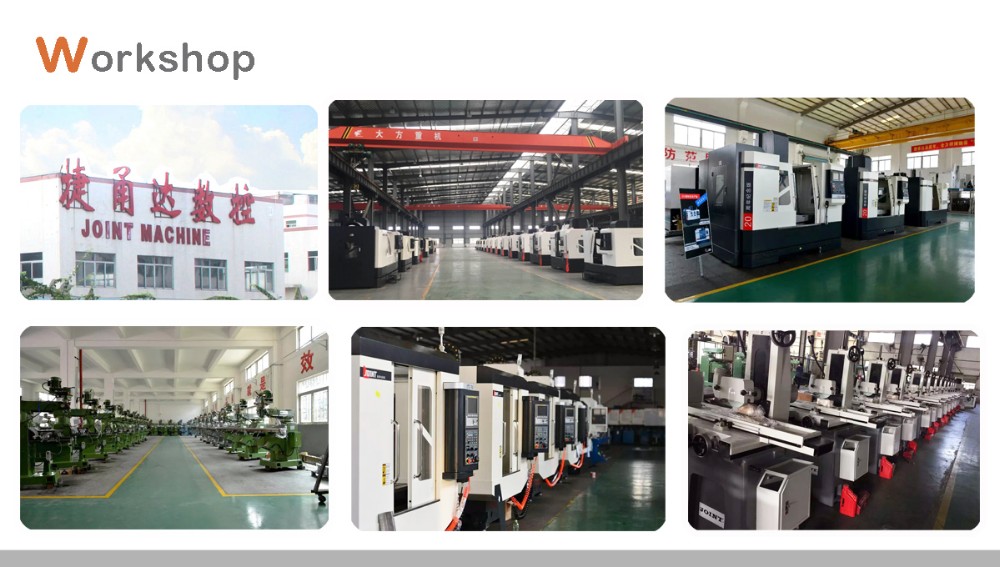

Production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Certifications

Certifications

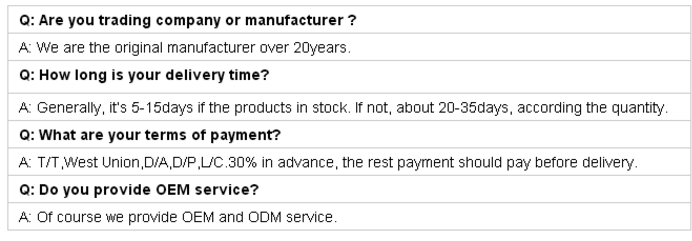

FAQ

FAQ

Product Features Strengthened cutting ,best choice for large mould and part processing · High quality resin sand casted,gantry type frame structure,Z axis employs laminated slide way system,which suits high rigidity and high precision parts processing. · Adopts temperature control technique(our patent) to ensure stability and accuracy of long-hour processing. · Adopts modular design,which made many different type of optimized model.that satisfys the different customer processing needs and fast delivery requirements.

Product Features Strengthened cutting ,best choice for large mould and part processing · High quality resin sand casted,gantry type frame structure,Z axis employs laminated slide way system,which suits high rigidity and high precision parts processing. · Adopts temperature control technique(our patent) to ensure stability and accuracy of long-hour processing. · Adopts modular design,which made many different type of optimized model.that satisfys the different customer processing needs and fast delivery requirements. Model | BTMC-0812 | |

| Processing Range | X Axis Travel | 820mm |

Y axis Travel | 1200mm | |

Z axis Travel | 500mm | |

Distance between spindle nose to worktable | 150-650mm | |

Table | Table size | 820*1200mm |

Load weight | 1100kg | |

T-Slot | 5-18-160 pcs-mm-mm | |

Spindle | Holder size | BT30 |

Diameter of Install | Φ100mm | |

Rivet Size | BT30 45°mm | |

Spindle Rotary speed | 12000RPM | |

Axis | X/Y axis motor power | 2kw |

cutting feed speed | 8m/min | |

Rapid speed of X/Y/Z axis | 18/18/12m/min | |

Accuracy | X/Y/Z axis Positioning accuracy | 0.08/0.01/0.006mm |

X/Y/Z axis Repeat positioning accuracy | 0.005/0.008/0.004mm | |

Other | Dimension | 3500*2400*2900mm |

Total Power | 15KVA | |

Weight | 5800kg | |

Packaging & Shipping

Packaging & Shipping  Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Certifications

Certifications

FAQ

FAQ

Related Keywords

Related Keywords