Best choice for large mould CNC gantry milling machine BTMC-1802

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Best choice for large mould CNC gantry milling machine BTMC-1802 Specifications 1.Serie 13 and serie 15 have either hard way X axes and linear way Y axis or X&Y axis are both linear way.For the other series, X&Y axes are all heavy-load roller linear way.Z axis for all models is rectangular slide way. 2. High quality resin sand casted, gantry type frame structure, Z axis employs laminated slide way system, which suits high rigidity and high precision parts processing. 3.Adopts temperature control technique (our patent) to ensure stability and accurancy of long-hour processing.

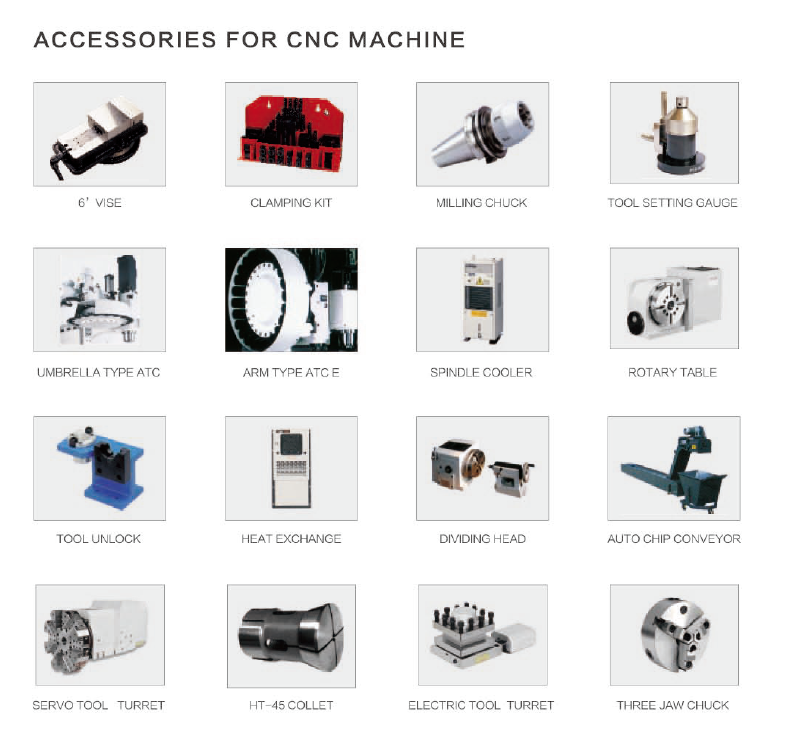

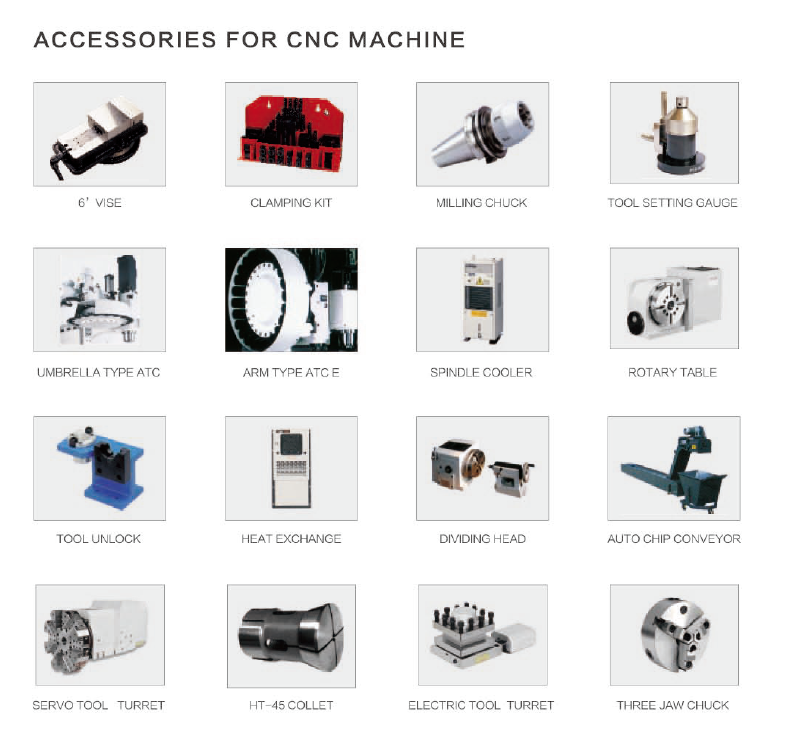

Accessories 1.Standard accessoires

2.Optional accessories ♦ Other Controllers ♦ 4 axis rotary table ♦ Through spindle water coolant ♦ Ring spary spindle ♦ ZF gear box ♦ 90 degree angle milling head  After-sales service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

After-sales service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

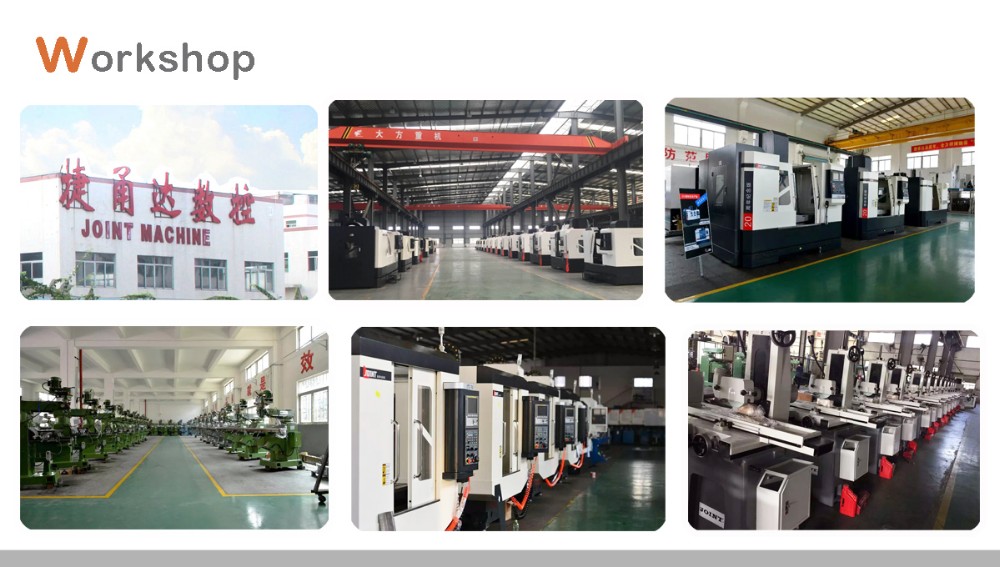

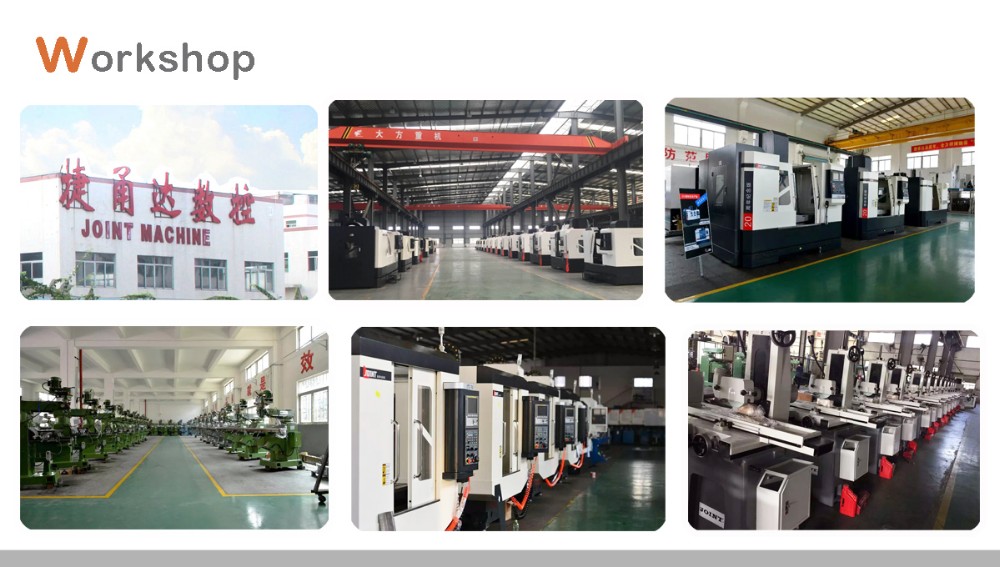

Workshop Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

Workshop Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

| Model | BTMC-1802 |

| Table size | 2000*1600 mm |

| Travel (Longitude) | 2000 mm |

| Travel (Crossward) | 2000 mm |

| Travel (Vertical) | 1000 mm |

| Gantry width | 2000 mm |

| Distance between spindle and table | 250-1250 mm |

| Spindle (Rotation speed) | 6000 rpm |

| Spindle (Taper) | BT50 |

| Spindle (Motor) | 22 kw |

| Rapid feed (Longitude) | 12 m/min |

| Rapid feed (Crossward) | 12 m/min |

| Rapid feed (Vertical) | 12 m/min |

| Cutting feed | 8 m/min |

| Positioning accuracy | 0.01 mm |

| Min.set moving unit | 0.001 mm |

| Dimension (L*W*H) | 7200*4100*4700 mm |

| Net weight | 24000 kg |

| Max.load of table | 4000 kg |

| Other model with same type/X axis travel | 1803/3000 |

| ♦ Spindle oil coolant | ♦ RS232 Interface |

| ♦ Heat exchanger | ♦ Warming light |

| ♦ Auto conveyor | ♦ Working light |

| ♦ Full enclosed cover | ♦ Tool and tool box |

| ♦ Auto lubrication system | ♦ Spindle encoder position system |

| ♦ Pneumatic system | ♦ Three Inner encoder position system |

| ♦ Operation unit | ♦ Fanuc /Mitsubishi Controller system |

After-sales service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

After-sales service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

Workshop Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

Workshop Our company builds modern production lines:CNC Milling Machine production line,Vertical Machine Center production line,Gantry Type Machine Center production line,Milling Machine production line,Surface Grinding Machine production line,EDM production line etc.

Related Keywords

Related Keywords