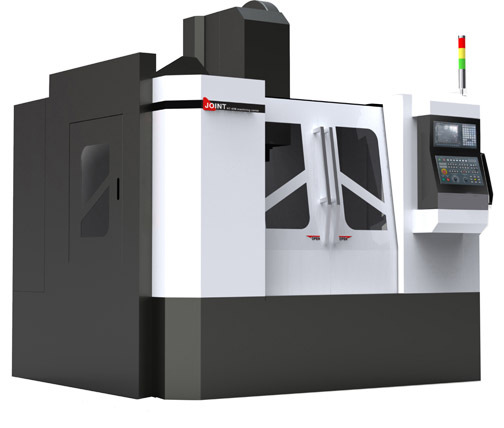

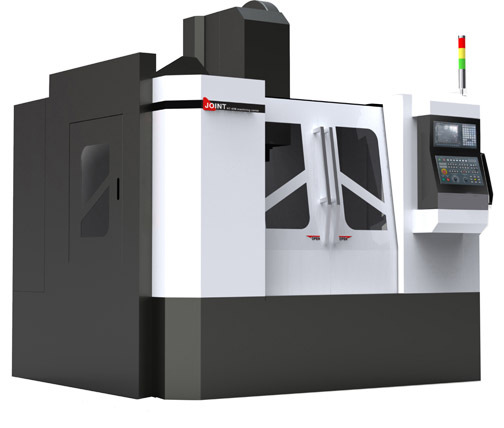

CNC double column milling machine BTMC-2505

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description Product Features 1.Serie 13 and serie 15 have either hard way X axes and linear way Y axis or X&Y axis are both linear way. For the other series, X&Y axes are all heavy-load roller linear way. Z axis for all models is rectangular slide way.

2.High quality resin sand casted, gantry type frame structure, Z axis employs laminated slide way system, which suits high rigidity and high precision parts processing.

3.Equipped with Europe imported gear box, rack and coupling (French brand gear driving box, Swiss brand rack and German brand coupling), Japanese / German Brand linear guide way and spindle bearing adopt. Lead screw, block nut, pulley, spindle, hydraulic balance system are from Taiwan the top brand’s top quality accessories, which ensure high precision, high quality and high stability.

4.Cooperated with Spainish brand Nicholas’s top class gantry type machining center in technology for many years. Continuously optimizes the mechanic features of gantry type machining center.

5.Adopts temperature control technique (our patent) to ensure stability and accuracy of long-hour processing.

6.Adopts modular design, which made many different type of optimized model, that satisfys the different customer processing needs and fast delivery requirements.

Special model  Gear head gantry type machining center ◆ Equipped with ZF gear reducer box (German) or gear type spindle-case (Taiwan), which can achieve high strength cutting

Gear head gantry type machining center ◆ Equipped with ZF gear reducer box (German) or gear type spindle-case (Taiwan), which can achieve high strength cutting

Multiple functional gantry type machining center ◆ Can be equipped with direct - connection type milling head, high speed spindle, which can achieve high rotation speed cutting. ◆ Can be equipped with Taiwan 90° angel milling head, which can meet simple horizontal processing requirement. ◆ Can be equipped with Taiwan universal milling head, which can meet achieve simple multiple angle processing needs. ◆Can be equipped with auto pentahedral milling head, which can achieve multi-surface high precision processing. Industry Focus

Industry Focus

car front bar mold household appliances mold car interior mold Accessories Standard Accessories ◆ Spindle oil cooler ◆ Heat exchanger ◆ Auto conveyor ◆ Full enclosed cover ◆ Auto lubrication system ◆ Pneumatic system ◆ RS232 Interface

car front bar mold household appliances mold car interior mold Accessories Standard Accessories ◆ Spindle oil cooler ◆ Heat exchanger ◆ Auto conveyor ◆ Full enclosed cover ◆ Auto lubrication system ◆ Pneumatic system ◆ RS232 Interface

◆ Operation unit ◆ Warming light ◆ Working light ◆ Tool and tool box ◆ Spindle encoder position system ◆ Three Inner encoder feedback system ◆ Fanuc /Mitsubishi Controller system

Optional Accessories ◆ Other Controllers ◆ 4 axis rotary table ◆ Through spindle water coolant ◆ Ring spray spindle ◆ ZF gear box ◆ 90 degree angle milling head

Related Products

Related Products

CNC milling machine 4K CNC machine center VMC-850C EDM ZNC-540 Our Service Warranty is a year. parts in the warranty would be free of charge due to its quality problem. Overseas service needs to be charged extra.

CNC milling machine 4K CNC machine center VMC-850C EDM ZNC-540 Our Service Warranty is a year. parts in the warranty would be free of charge due to its quality problem. Overseas service needs to be charged extra.

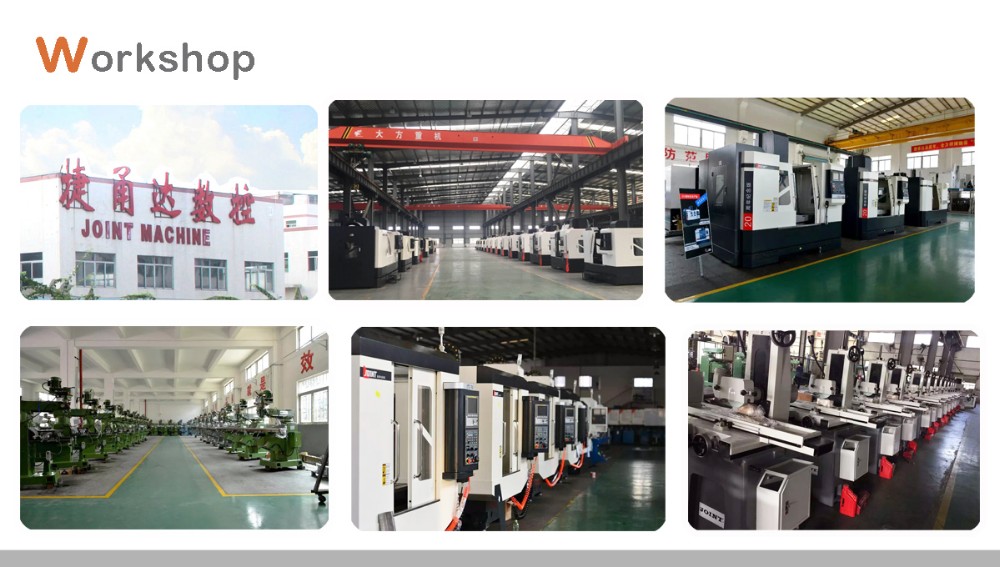

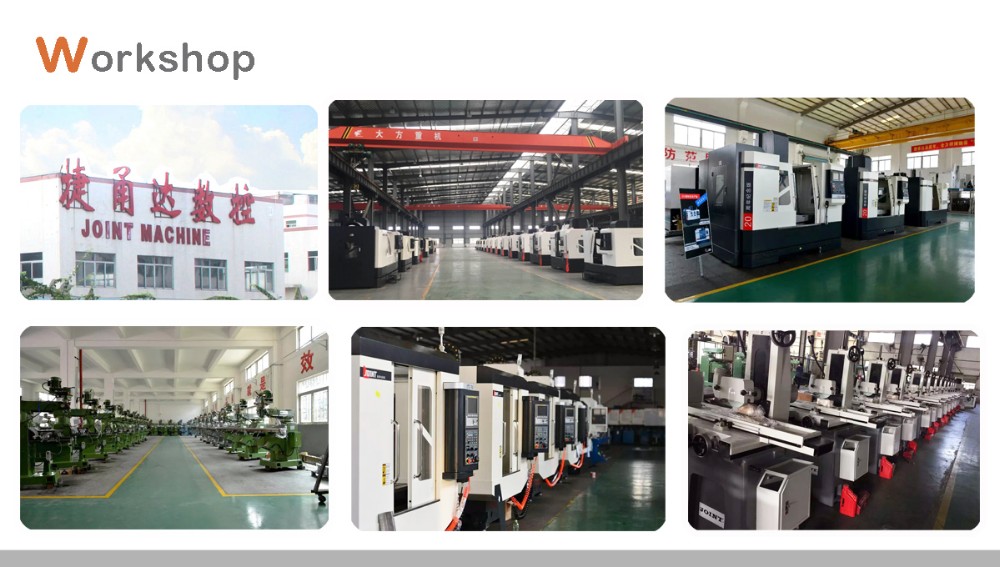

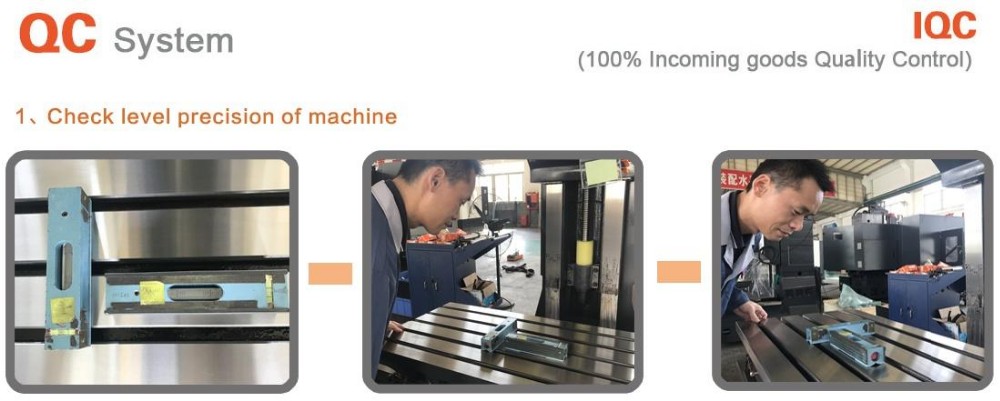

Our Company

Our Company

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

Q: How long is your delivery time? A: Generally it is 15-25 days if the goods are in stock. or it is 45-60 days if the goods are not in stock, it is according to quantity.

Q: How many years have your company established? A: 21 years, our company built in 1995.

Q: What is your terms of payment ? A: 30% in advance.and the rest payment should pay before delivery.

2.High quality resin sand casted, gantry type frame structure, Z axis employs laminated slide way system, which suits high rigidity and high precision parts processing.

3.Equipped with Europe imported gear box, rack and coupling (French brand gear driving box, Swiss brand rack and German brand coupling), Japanese / German Brand linear guide way and spindle bearing adopt. Lead screw, block nut, pulley, spindle, hydraulic balance system are from Taiwan the top brand’s top quality accessories, which ensure high precision, high quality and high stability.

4.Cooperated with Spainish brand Nicholas’s top class gantry type machining center in technology for many years. Continuously optimizes the mechanic features of gantry type machining center.

5.Adopts temperature control technique (our patent) to ensure stability and accuracy of long-hour processing.

6.Adopts modular design, which made many different type of optimized model, that satisfys the different customer processing needs and fast delivery requirements.

Gear head gantry type machining center ◆ Equipped with ZF gear reducer box (German) or gear type spindle-case (Taiwan), which can achieve high strength cutting

Gear head gantry type machining center ◆ Equipped with ZF gear reducer box (German) or gear type spindle-case (Taiwan), which can achieve high strength cuttingMultiple functional gantry type machining center ◆ Can be equipped with direct - connection type milling head, high speed spindle, which can achieve high rotation speed cutting. ◆ Can be equipped with Taiwan 90° angel milling head, which can meet simple horizontal processing requirement. ◆ Can be equipped with Taiwan universal milling head, which can meet achieve simple multiple angle processing needs. ◆Can be equipped with auto pentahedral milling head, which can achieve multi-surface high precision processing.

Industry Focus

Industry Focus

car front bar mold household appliances mold car interior mold Accessories Standard Accessories ◆ Spindle oil cooler ◆ Heat exchanger ◆ Auto conveyor ◆ Full enclosed cover ◆ Auto lubrication system ◆ Pneumatic system ◆ RS232 Interface

car front bar mold household appliances mold car interior mold Accessories Standard Accessories ◆ Spindle oil cooler ◆ Heat exchanger ◆ Auto conveyor ◆ Full enclosed cover ◆ Auto lubrication system ◆ Pneumatic system ◆ RS232 Interface◆ Operation unit ◆ Warming light ◆ Working light ◆ Tool and tool box ◆ Spindle encoder position system ◆ Three Inner encoder feedback system ◆ Fanuc /Mitsubishi Controller system

Optional Accessories ◆ Other Controllers ◆ 4 axis rotary table ◆ Through spindle water coolant ◆ Ring spray spindle ◆ ZF gear box ◆ 90 degree angle milling head

Related Products

Related Products

CNC milling machine 4K CNC machine center VMC-850C EDM ZNC-540 Our Service Warranty is a year. parts in the warranty would be free of charge due to its quality problem. Overseas service needs to be charged extra.

CNC milling machine 4K CNC machine center VMC-850C EDM ZNC-540 Our Service Warranty is a year. parts in the warranty would be free of charge due to its quality problem. Overseas service needs to be charged extra. Our Company

Our Company

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

FAQ Q: Are you trading company or manufacturer ? A: We are factory.Q: How long is your delivery time? A: Generally it is 15-25 days if the goods are in stock. or it is 45-60 days if the goods are not in stock, it is according to quantity.

Q: How many years have your company established? A: 21 years, our company built in 1995.

Q: What is your terms of payment ? A: 30% in advance.and the rest payment should pay before delivery.

Related Keywords

Related Keywords