Foshan Factory High Efficiency Injection Molding Machine with In-Mold Labeling System

-

$60000.001-1 set

-

$25000.00≥2 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Product Overview

IML Container Injection Molding

In fast consumable times, In Mold Labeling system is widely used in product package, thanks to its good characteristics of perfect surface, waterproof, anti-corrosion, packaging security and protection from counterfeiting.

With the label being the same material as the IML containers, counterfeiting by removing the label and inventory serialized barcode is impossible. Additionally, sustainability is enhanced because the label and container can be recycled together after many years of research and development.

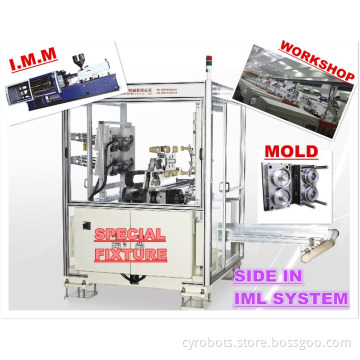

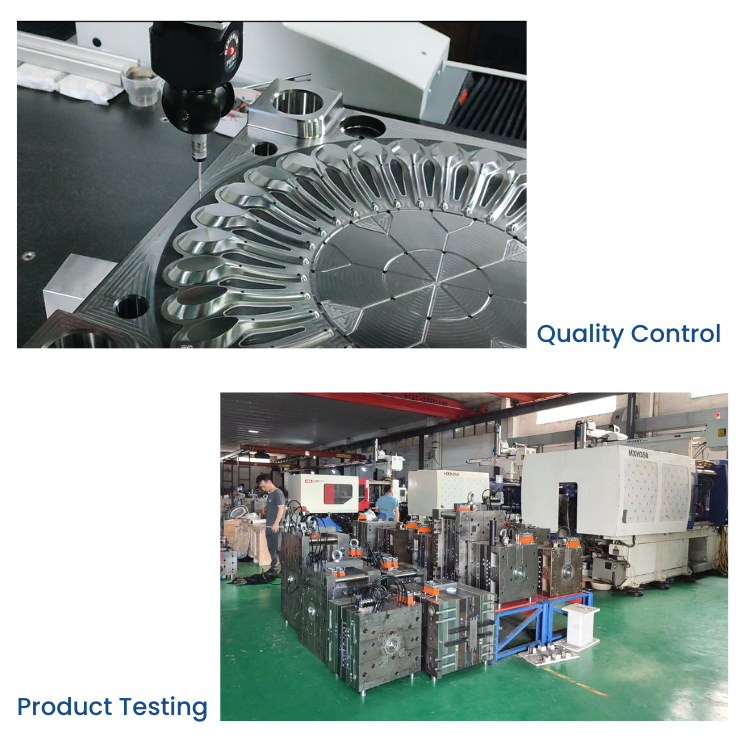

CHUANY team is fully capable of integrally controlling the IML key technology, and flexibly making various IML turnkey solutions,offering the ability to integrate IML mold, machines, automation, and post-mold handling equipment with our tooling solutions to optimize productivity and lower overall part cost.

With the label being the same material as the IML containers, counterfeiting by removing the label and inventory serialized barcode is impossible. Additionally, sustainability is enhanced because the label and container can be recycled together after many years of research and development.

CHUANY team is fully capable of integrally controlling the IML key technology, and flexibly making various IML turnkey solutions,offering the ability to integrate IML mold, machines, automation, and post-mold handling equipment with our tooling solutions to optimize productivity and lower overall part cost.

Products Description

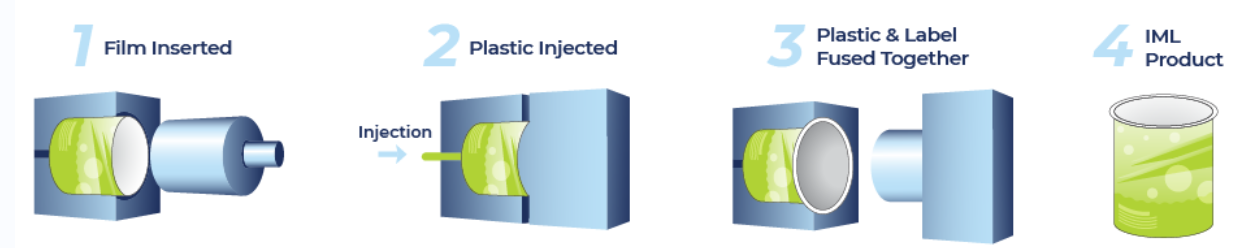

What is in mold labeling?

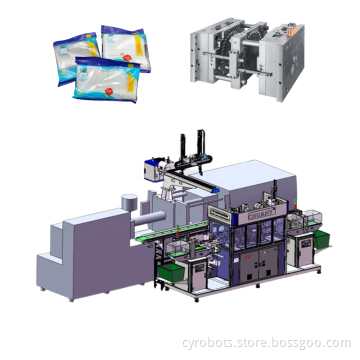

In injecting molding, the design label is placed into the mold before fusing together with the container. After the plastic pellets are heated, the resin is injected into the mold where it seamlessly combines with the label.

Benefits of IML (In mold labeling)

1. Cost-effective

2. Environment-friendly

3. Durability

For mass production, in-mold labeling containers take less time to manufacture because it is produced and decorated in one step to form a single product. In comparison to PML, in-mold labeling is typically more cost-efficient because it is without the expense of time, labor and floor space; IML also reduces inventory like post-mold paper labels and adhesives.

2. Environment-friendly

IML and closures consist of the same material and can therefore be fully recycled

3. Durability

The water resistance of in-mold labeling makes it a reliable labeling option that can withstand both humid environments and extreme temperature fluctuations (freezing/cooling conditions). In contrast to pressure sensitive labeling, IML is a permanent design method with excellent impact and scratch resistance because it fuses permanently to the container.

4. Outstanding print quality

In-mold labeling provides high resolution colors and images for labels. IML is compatible with a wide range of colors and can be displayed on both sides of the package.

5. Flexible usage: Suitable for side label, round labeling, three sides labeling, all-around labeling, five surface labeling

Product Features

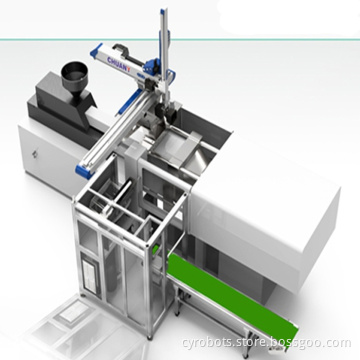

1. It is common to use on products made in 160T-400T injection molding machines.

2. It is widely used on thin wall IML products, min cycle time is 5s.

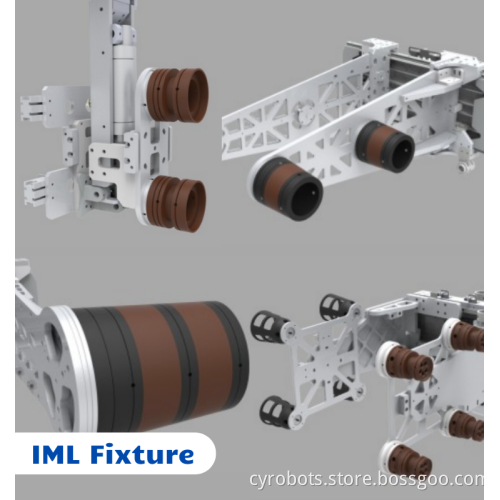

3. Moving part adopts Rexroth guide rail, imported servo motor, and reducer, and the labeling part adopts high-performance vacuum pump and imported static system, which is fast, stable, and accurate.

4. Replaceable label stock and fixtures, using one system to make similar labels on different products, will reduce the investment for more IML production in the future

5. Stack robot and conveyor are equipped in this system which leads to fully automatic production.

6. Our system is designed based on Euro food grade demand with a CE mark.

Application

In-Mold Labeling Container (IML) products have expanded rapidly to new market applications with single dimension, 3-5 sided and wrap-around applications for food, household, medical and cosmetic industries.

* Food packaging (e.g. cups, trays, jars, ice cream, yogurts, prepared meals, butter, sauce)

* Household packaging (e.g. buckets, containers)

* Medical and cosmetic (e.g. tubes, jars, bottles)

* Food packaging (e.g. cups, trays, jars, ice cream, yogurts, prepared meals, butter, sauce)

* Household packaging (e.g. buckets, containers)

* Medical and cosmetic (e.g. tubes, jars, bottles)

Q1: Where is your factory located?

A1: Our factory is located in Foshan, Guangdong.

Q2: Are you an integrated supplier for mold, robot, automation system and auxiliary?

A1: Our factory is located in Foshan, Guangdong.

Q2: Are you an integrated supplier for mold, robot, automation system and auxiliary?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

.

Q3: Will you offer the pre-sales service?

A3: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water. electrical, machine layout in factory, etc.

Q4: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A4: Surely, we have many experiences technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q5: What is the warranty of the machine?

A5: The whole machine’s warranty period is 12 months and key parts will be depended.

.

Q3: Will you offer the pre-sales service?

A3: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water. electrical, machine layout in factory, etc.

Q4: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A4: Surely, we have many experiences technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q5: What is the warranty of the machine?

A5: The whole machine’s warranty period is 12 months and key parts will be depended.

Related Keywords

Related Keywords

You May Also Like

You May Also Like