IML Labeling System for Food and Non-Food Injection Molding Applications

- Min. Order:

- 1 unit

- Min. Order:

- 1 unit

- Port:

- Foshan, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 300 Unit/Units per Month |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Port: | Foshan,Guangzhou,Shenzhen |

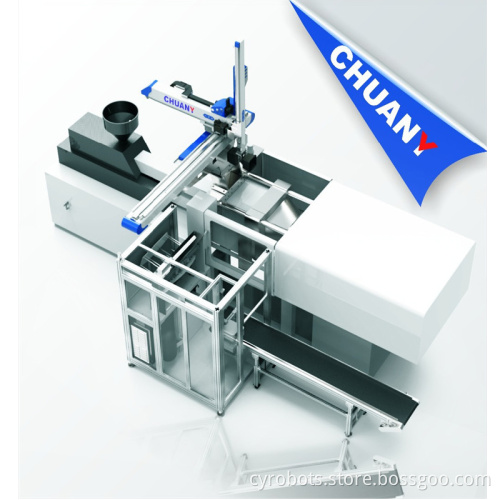

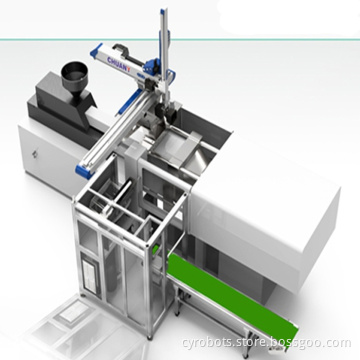

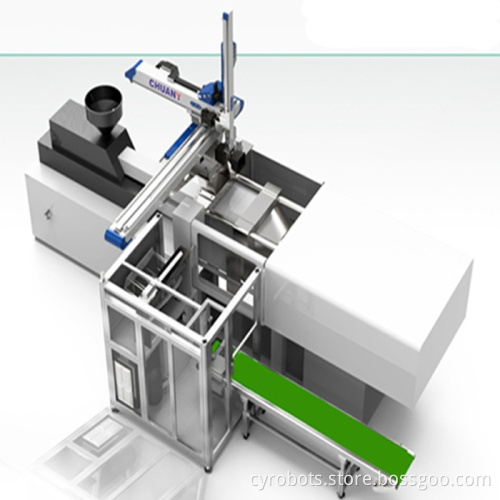

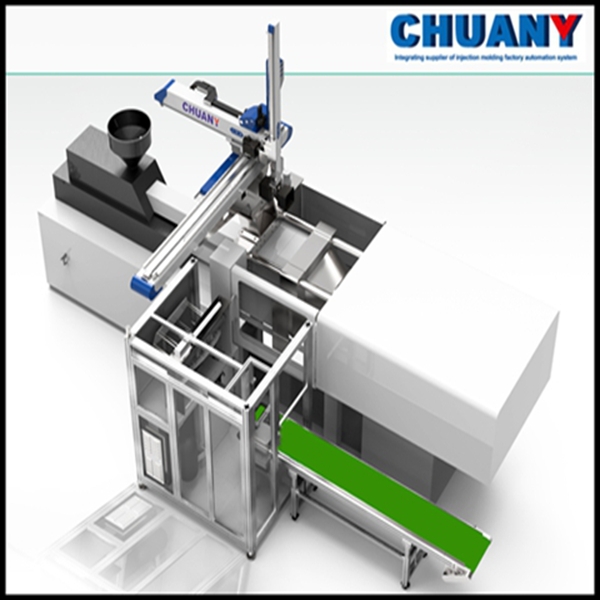

High Speed Top series In-Mold Labeling Systems includes the following,see data chart for opitions or contact us for additional customization :

◊ Applicable for various products with good universality.

◊ Applicable for injection machine 160-400T,max suitable for 5L buckets.

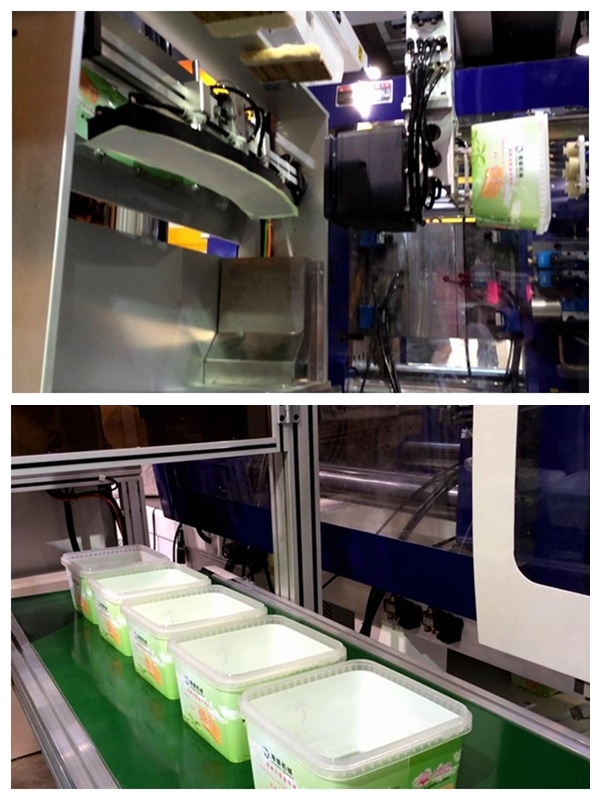

◊ Full automatic collect and stack system,realizing maximum production.

◊ EUROMAP standard.

◊ Most efficient injection molding machine,manipulator,labeling machine

◊ High stable system and fiexible adjustment program

◊ Competitively priced

◊ 1 year warranty and Automation plastic high level of service and support except:gripper and free parts.

Main specification:

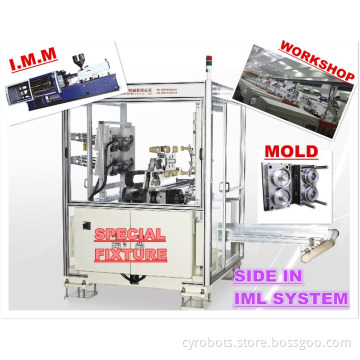

Standard Layout | Product Design | Label Design | Label Thickness |

TOP Entry Robot | circle | circle | optional |

Label cassette (Magazine) | Round | U-shape | optional |

EOAT (End of Arm Toolings) | Wrap-around | overrall |

|

Static charger | Oval | Wrap-around |

|

Vacuum pump | Polygonal | Wrap-around |

|

Safety frame |

| Lenticular |

|

Stacking unit (Optional) |

|

|

|

Technical Specification:

Entry stroke | 1400mm/optional |

Euromap interface | E12 / E67 |

Dimensions of system | robot:3500*1700*2200mm label strok:1800*1500*2000mm |

Controller | "Mobile commander with colorful touch panel." |

| Easy operation / programming |

Driven:

Entry axis | Servo |

EOAT | Servo / Pneumatic |

Cassette | Servo |

Stacking | Servo |

Power consumption | 3.5 KVA |

Capacity | AC220V 50/60Hz |

Air consumption | 200 NL/cycle |

Welcome to CHUANYI Precision Machinery Co.,Ltd was created in 2008 we has insisted on the operation principle of "TOP-QUALITY,BROAD&PROFOUND" at best of the robot designs ans technologies to provide the plastic industry with the most complet line of multifunctional and all automatic plastic injection molding robots equipped with the highest level of mechanical quality and system controls available with our owns complete manufacture,development,assembling,sale and service.

OUR WORKSHOP

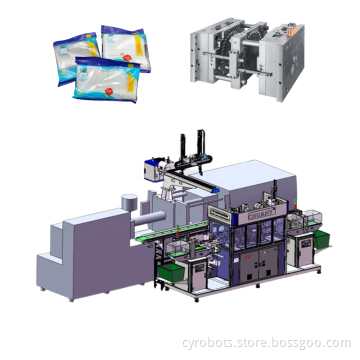

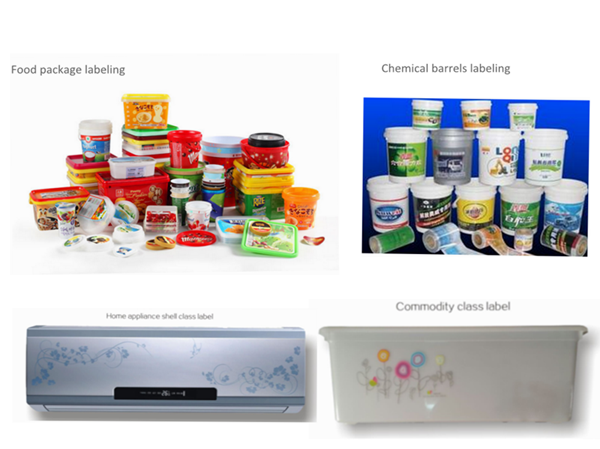

IML APPLICATION

Our Exhibition

Advanced technology:

a. Many years experience in plastic industry Automation system.

b. All components are new, some core components are imported from

German (TKD), Japan (Sampo/THK/ /Panasonic), USA (Weipu) etc.

c. We do 100% testing before shipment.

d. Warranty is 12 months for all products.

e. Provide professional automation system by customize requirements, saving time and cost for you, enjoy the one-stop shopping.

f. Stand by service, our engineer or technician will visit your esteemed company for

installation and debugging of machine.

♦ Why is in mould labeling is so popular?

Beacause offer these advantages:

1. Lower costs than other pre-decorating methods.

2.No extra labeling step or equipment.

3. In-case product filling and capping.

4. Increased packaging line speeds.

5. Reduces in-house container inventory.

6. Reduced product weight.

7. Inproved appearance.

8. Better stain resistance.

9. Improved sidewall strength.

10. Better squeeze resistance.

Related Keywords