Factory price 365nm 395nm uv led for curing

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

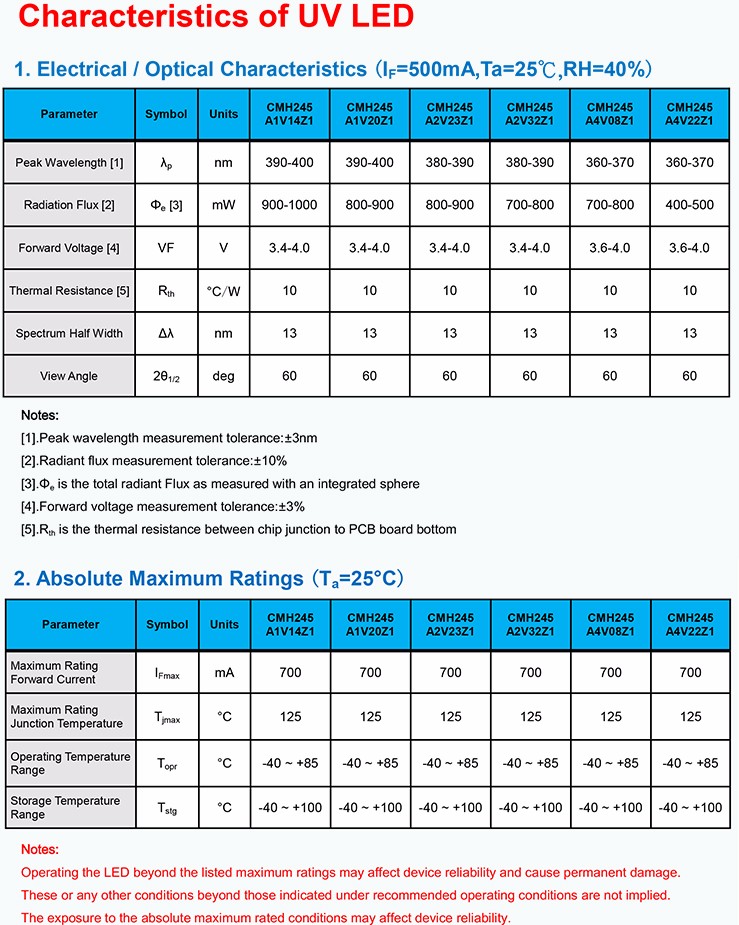

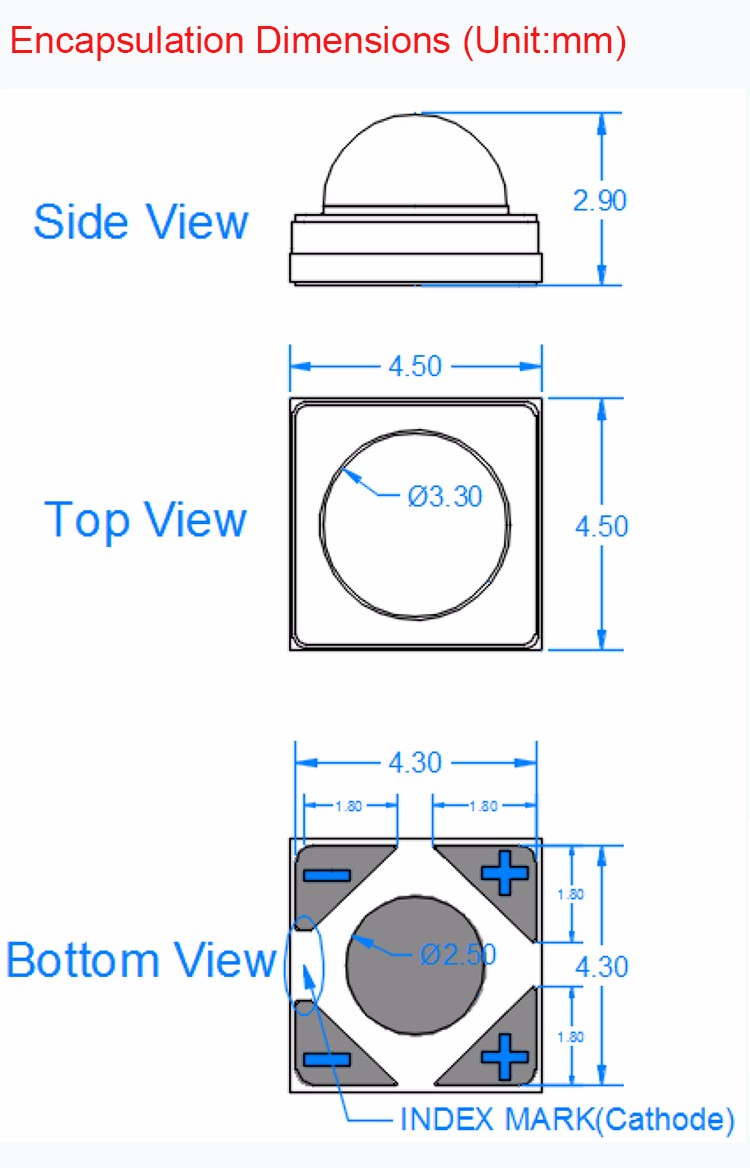

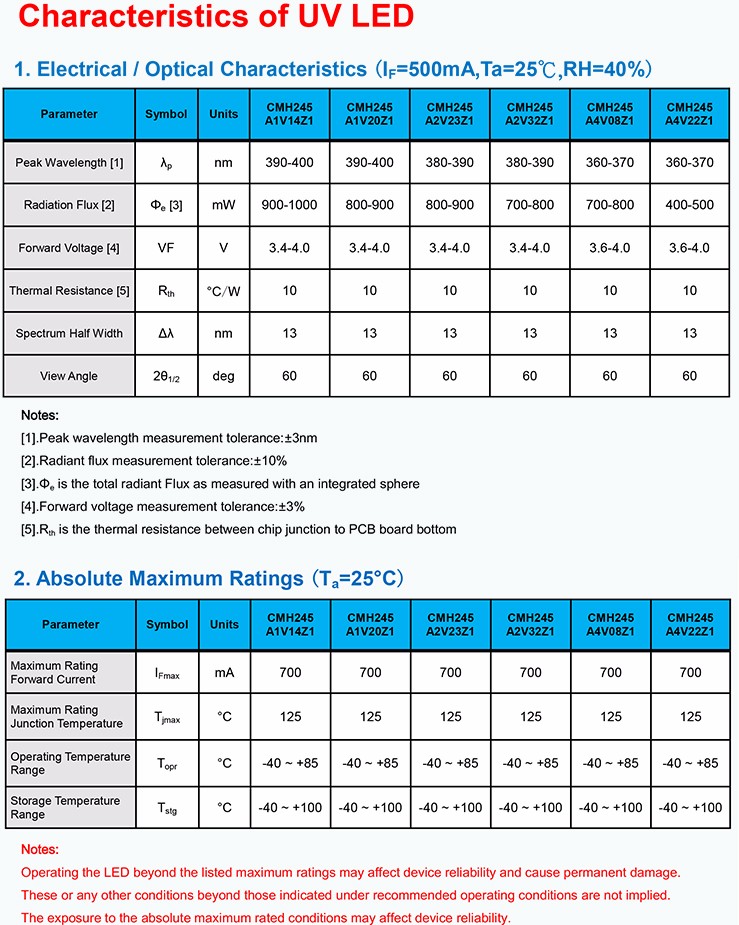

Product Description UV LED CMH 395nm 385nm 365nm CMH technology platform is a kind of package technology which adopts ceramic, metal, hard glass as package materials. CMH technology platform originates independent intellectual property owned by HCEN Technology CO., LTD, which is suitable for vacuum encapsulation, especially suitable for ensuring reliability of deep UV products.

Features: · CMH real inorganic package

· Hermetic package

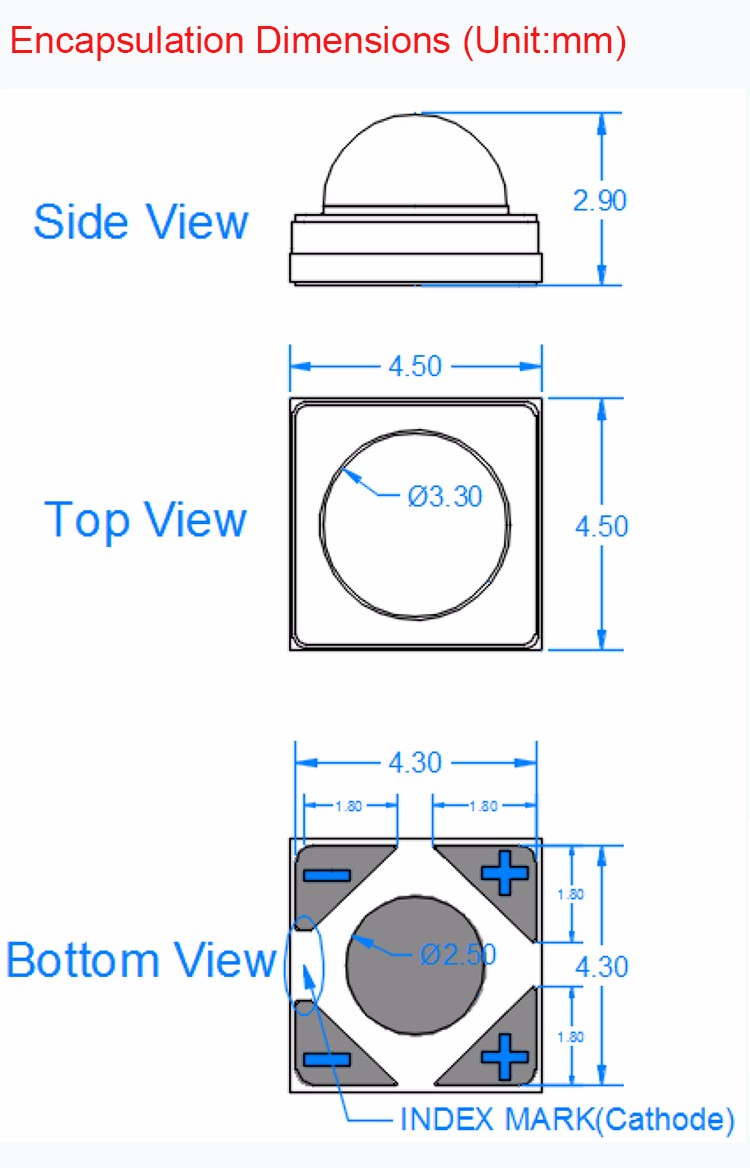

· Dimensions: 4.4x4.4x2.9mm

· Long operating lifespan: 30,000 hours

· High-reliability

· Superior ESD protection

· With RoHS Directive-compliant

· Angle: 60 degrees (optional)

Detailed Images

Detailed Images

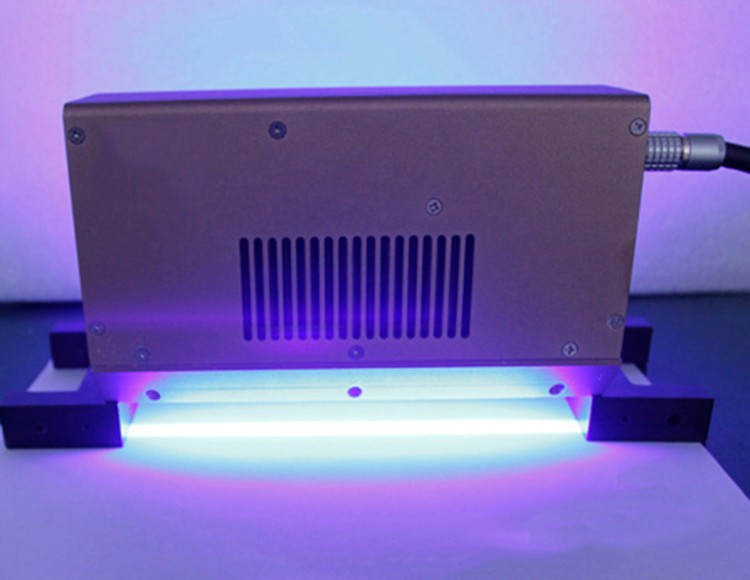

Applications UVA LED CMH 395nm 385nm 365nm can be used to UV curing, Phototherapy, Bio-analysis/detection...

Applications UVA LED CMH 395nm 385nm 365nm can be used to UV curing, Phototherapy, Bio-analysis/detection...

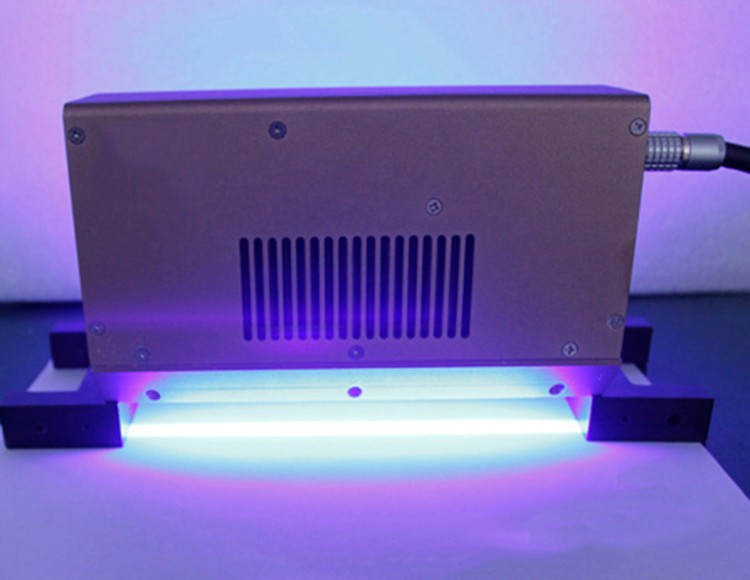

UV curing

UV curing

Nail-painting

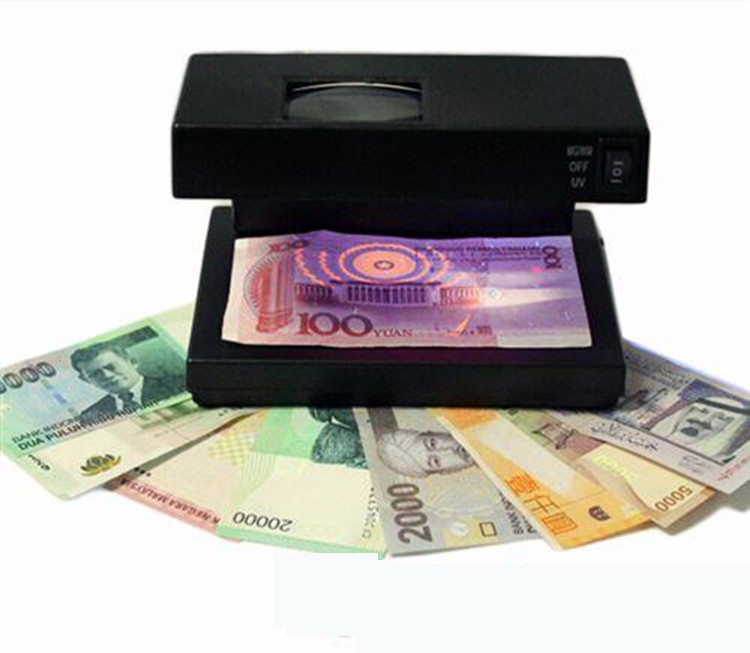

Counterfeit detection

Our Company

HCEN Technology Group is professional engaged in ultraviolet light emitting diode (UV LED) lamp encapsulation, applications and solutions, which are widely used in UV curing, UV printing, UV medical treatment, and Sterilization field.

HCEN Technology Group is professional engaged in ultraviolet light emitting diode (UV LED) lamp encapsulation, applications and solutions, which are widely used in UV curing, UV printing, UV medical treatment, and Sterilization field.

With a forward-looking decision, independent proprietary UV LED packaging technology and professional manufacture, since the establishment in 2014, HCEN grows rapidly, based in Shenzhen, with offices and technical support teams in many countries and regions around the world, more than 200 employees and excellent global customers base .

www.hcengroup.com

Our R &D Team Hcen Research and Development HCEN Group invested 10% of sales revenge as a research and development costs each year, strived to build professional R&D network and knowledge management platform all over the Asia, the US, and Europe, to create technology service-oriented enterprises.

Currently, Hcen owned a more than 50 people R & D team, and it will be stronger and stronger.

Our factory

Our factory  200 people factory Our factory is in Zhongshan, HCEN continue to achieve a pioneering achievement in the field of LED packaging technology and applied research. Independent research and development of ultraviolet light-emitting diodes all inorganic ceramic, hard glass and metal technology(CMH all inorganic technology ) made a groundbreaking achievement, win the advantages of technology and manufacturing in the global UV LED industry.

200 people factory Our factory is in Zhongshan, HCEN continue to achieve a pioneering achievement in the field of LED packaging technology and applied research. Independent research and development of ultraviolet light-emitting diodes all inorganic ceramic, hard glass and metal technology(CMH all inorganic technology ) made a groundbreaking achievement, win the advantages of technology and manufacturing in the global UV LED industry.

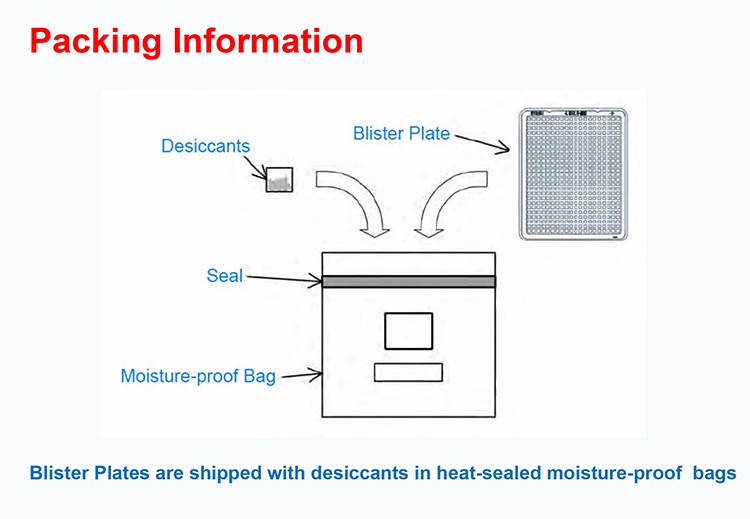

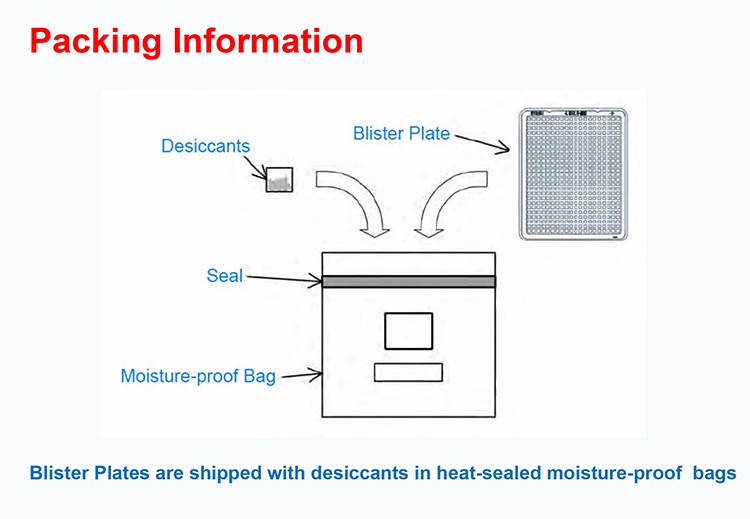

Packing & Delivery Cautions 1.Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics.

Cautions 1.Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics.

· When handling the product with tweezers, be careful not to apply excessive force to glass LENS as it may cause the surface scratch.

· Dropping the product may cause damage.

2.Electrostatic Discharge (ESD) · The product are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. When handling the products, the following measure against electrostatic dis-charge are strongly recommended:

Eliminating wrist strap, ESD footwear, clothes, and floors

Grounded workstation equipment and tools

ESD table/shelf mat made of conductive materials

· Ensure that tools, jigs and machines that are being used are properly grounded and that proper grounding techniques are used in work areas. For devices/equipment that mount the LEDs, protection against surge voltages should also be used.

· The customer is advised to check if the LEDs are damage by ESD When performing the characteristics inspection of the LEDs in the application. Damage can be detected with a forward voltage measurement at low current(≤1mA).

3. Eye Safety · Please proceed with caution when handling any UVLEDs driven at low or high current. Since UV light can be harmful to eyes, do Not look directly into the UV light, even through an optical instrument.

· UV protective glasses are required to use in order to avoid damage by UV light in case of viewing UV light directly.

Features: · CMH real inorganic package

· Hermetic package

· Dimensions: 4.4x4.4x2.9mm

· Long operating lifespan: 30,000 hours

· High-reliability

· Superior ESD protection

· With RoHS Directive-compliant

· Angle: 60 degrees (optional)

Detailed Images

Detailed Images

Applications UVA LED CMH 395nm 385nm 365nm can be used to UV curing, Phototherapy, Bio-analysis/detection...

Applications UVA LED CMH 395nm 385nm 365nm can be used to UV curing, Phototherapy, Bio-analysis/detection...

UV curing

UV curing Nail-painting

Counterfeit detection

Our Company

HCEN Technology Group is professional engaged in ultraviolet light emitting diode (UV LED) lamp encapsulation, applications and solutions, which are widely used in UV curing, UV printing, UV medical treatment, and Sterilization field.

HCEN Technology Group is professional engaged in ultraviolet light emitting diode (UV LED) lamp encapsulation, applications and solutions, which are widely used in UV curing, UV printing, UV medical treatment, and Sterilization field.With a forward-looking decision, independent proprietary UV LED packaging technology and professional manufacture, since the establishment in 2014, HCEN grows rapidly, based in Shenzhen, with offices and technical support teams in many countries and regions around the world, more than 200 employees and excellent global customers base .

www.hcengroup.com

Our R &D Team Hcen Research and Development HCEN Group invested 10% of sales revenge as a research and development costs each year, strived to build professional R&D network and knowledge management platform all over the Asia, the US, and Europe, to create technology service-oriented enterprises.

Currently, Hcen owned a more than 50 people R & D team, and it will be stronger and stronger.

Our factory

Our factory  200 people factory Our factory is in Zhongshan, HCEN continue to achieve a pioneering achievement in the field of LED packaging technology and applied research. Independent research and development of ultraviolet light-emitting diodes all inorganic ceramic, hard glass and metal technology(CMH all inorganic technology ) made a groundbreaking achievement, win the advantages of technology and manufacturing in the global UV LED industry.

200 people factory Our factory is in Zhongshan, HCEN continue to achieve a pioneering achievement in the field of LED packaging technology and applied research. Independent research and development of ultraviolet light-emitting diodes all inorganic ceramic, hard glass and metal technology(CMH all inorganic technology ) made a groundbreaking achievement, win the advantages of technology and manufacturing in the global UV LED industry. Packing & Delivery

Cautions 1.Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics.

Cautions 1.Handling precautions · Do not handle the LEDs with bare hands as it will contaminate the LENS surface and may affect the optical characteristics.· When handling the product with tweezers, be careful not to apply excessive force to glass LENS as it may cause the surface scratch.

· Dropping the product may cause damage.

2.Electrostatic Discharge (ESD) · The product are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. When handling the products, the following measure against electrostatic dis-charge are strongly recommended:

Eliminating wrist strap, ESD footwear, clothes, and floors

Grounded workstation equipment and tools

ESD table/shelf mat made of conductive materials

· Ensure that tools, jigs and machines that are being used are properly grounded and that proper grounding techniques are used in work areas. For devices/equipment that mount the LEDs, protection against surge voltages should also be used.

· The customer is advised to check if the LEDs are damage by ESD When performing the characteristics inspection of the LEDs in the application. Damage can be detected with a forward voltage measurement at low current(≤1mA).

3. Eye Safety · Please proceed with caution when handling any UVLEDs driven at low or high current. Since UV light can be harmful to eyes, do Not look directly into the UV light, even through an optical instrument.

· UV protective glasses are required to use in order to avoid damage by UV light in case of viewing UV light directly.

Related Keywords

Related Keywords

You May Also Like

You May Also Like