Household Appliance Wash Gargle Rapid Prototypes Maker

- Delivery Time:

- 8 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description Item name: Household Appliance Wash Gargle Rapid Prototypes Makerd Prototypes Material: polycarbonate (PC),ABS

Tolerance : 0.04 mm Product Size: Custom Process way: CNC machining Surface Treatment: Polish, Painting Devery Time: 8 days Available 3D files format: Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t Payment term: T/ T ( 50% Prepaid, pay the balance before shipment) , Paypal, L/C, Western Union More Options: Available Materials

Available 3D files format: Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t Payment term: T/ T ( 50% Prepaid, pay the balance before shipment) , Paypal, L/C, Western Union More Options: Available Materials

Plastic: ABS, POM, PMMA, PVC, PP, PA, BT,PC,TPE etc.

Matel: Aluminum etc .

Wood and other specialist materials .

Standard finishing for all materials

1) milling; 2) brushing; 3)polishing; 4) bead blasting;

5) painting; 6) silk-screen; 7) oil spraying etc.

Surface processing

Natural, polish, polishing, painting, silk-screen, chrome plated, electroplated etc.

Company Information SHENZHEN TUOWEI MODEL TECHNOLOGIEC LTD.

Company Information SHENZHEN TUOWEI MODEL TECHNOLOGIEC LTD.

We specialize in Prototype making since 2002.Our factory utilizes more than 3000 sq. Meters of Production Space and state of the art Rapid Prototyping Equipment. We offer Subtractive Manufacturing services. With more than 45 CNC Routing Machines and 5 EDM Spark Machines, we provide a variety of production processes and options. We offer Mold Making services. Options include: PIM Plastic Injection Molding, RIM Reaction Injection Molding, Vacuum Casting, Pressure Casting, and PDC Pressure Die Casting. We offer Additive Manufacturing services. Options include: OBJET 3D Printing, as well as SLA, SLS.

Our Services 1. 3 Axis & 5 Axis CNC Machining, ideal for Small Batch Productions 2. 3D Printing (OBJET / SLA / SLS / FDM), ideal for Test Models

Our Services 1. 3 Axis & 5 Axis CNC Machining, ideal for Small Batch Productions 2. 3D Printing (OBJET / SLA / SLS / FDM), ideal for Test Models

3. RTV Vacuum Casting & Pressure Casting, ideal Small Batch Productions 4. RIM Reaction Injection Molding, ideal for Low Volume Mass Productions 5. PIM Plastic Injection Molding, ideal for High Volume Mass Productions 6. Finishing: Etching, Anodizing, Chrome Plating, Powder Coating, PU & UV Painting 7.ID Industrial Design: Strategic Design, Design Rendering, & Structural Design

Certifications Packaging & Shipping Packaging:

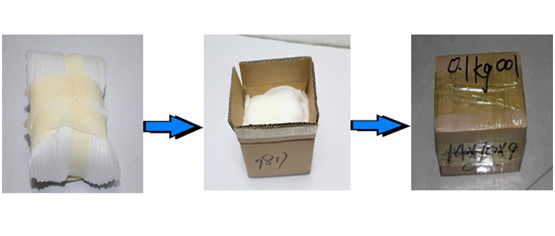

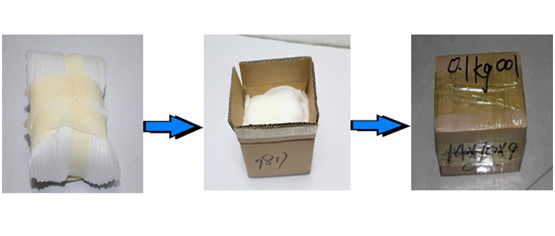

Packaging & Shipping Packaging:

1 White paper

2 Plastic foam or bubble carton

3 Clear protection films

4 Plastic foam or bubble carton

5 Carton case or wooden case or as per consumer's requirements

FAQ Are you manufacture or trad company? We are factory, located in China Shenzhen province, near Shenzhen air port east.

FAQ Are you manufacture or trad company? We are factory, located in China Shenzhen province, near Shenzhen air port east.

Machine: 5 CNC Machines. 1 3d printer, 1 CNC lather machine etc. How about the QC? After the part has been machined it is checked against the drawing specifications

Before and after the finishing department has painted and polished the part it is inspected

The manager will personally check the products before they are packaged and sent for shipping What test tool do you have ? Hardness Tester (Shore A), Hardness Tester (Shore D), Humidity Gage, Color Standards,

Texture Standards , Color Scanner, Height Gage, Angle Gage, Hole Gage, Caliper (300MM),

Caliper (600MM), Caliper (1000MM), Color Assesment Cabinet. What Certificate do you have ?

ISO9001:2008

What would be provided to you when we need to make prototype?

The avaliable files for 3D Printing is : 3D drawings of .STL format and CMF ( Color, Material, Finish) Make Modles,Your Way!

Tolerance : 0.04 mm Product Size: Custom Process way: CNC machining Surface Treatment: Polish, Painting Devery Time: 8 days

Available 3D files format: Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t Payment term: T/ T ( 50% Prepaid, pay the balance before shipment) , Paypal, L/C, Western Union More Options: Available Materials

Available 3D files format: Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t Payment term: T/ T ( 50% Prepaid, pay the balance before shipment) , Paypal, L/C, Western Union More Options: Available MaterialsPlastic: ABS, POM, PMMA, PVC, PP, PA, BT,PC,TPE etc.

Matel: Aluminum etc .

Wood and other specialist materials .

Standard finishing for all materials

1) milling; 2) brushing; 3)polishing; 4) bead blasting;

5) painting; 6) silk-screen; 7) oil spraying etc.

Surface processing

Natural, polish, polishing, painting, silk-screen, chrome plated, electroplated etc.

Company Information SHENZHEN TUOWEI MODEL TECHNOLOGIEC LTD.

Company Information SHENZHEN TUOWEI MODEL TECHNOLOGIEC LTD. We specialize in Prototype making since 2002.Our factory utilizes more than 3000 sq. Meters of Production Space and state of the art Rapid Prototyping Equipment. We offer Subtractive Manufacturing services. With more than 45 CNC Routing Machines and 5 EDM Spark Machines, we provide a variety of production processes and options. We offer Mold Making services. Options include: PIM Plastic Injection Molding, RIM Reaction Injection Molding, Vacuum Casting, Pressure Casting, and PDC Pressure Die Casting. We offer Additive Manufacturing services. Options include: OBJET 3D Printing, as well as SLA, SLS.

Our Services 1. 3 Axis & 5 Axis CNC Machining, ideal for Small Batch Productions 2. 3D Printing (OBJET / SLA / SLS / FDM), ideal for Test Models

Our Services 1. 3 Axis & 5 Axis CNC Machining, ideal for Small Batch Productions 2. 3D Printing (OBJET / SLA / SLS / FDM), ideal for Test Models 3. RTV Vacuum Casting & Pressure Casting, ideal Small Batch Productions 4. RIM Reaction Injection Molding, ideal for Low Volume Mass Productions 5. PIM Plastic Injection Molding, ideal for High Volume Mass Productions 6. Finishing: Etching, Anodizing, Chrome Plating, Powder Coating, PU & UV Painting 7.ID Industrial Design: Strategic Design, Design Rendering, & Structural Design

Certifications

Packaging & Shipping Packaging:

Packaging & Shipping Packaging:1 White paper

2 Plastic foam or bubble carton

3 Clear protection films

4 Plastic foam or bubble carton

5 Carton case or wooden case or as per consumer's requirements

FAQ Are you manufacture or trad company? We are factory, located in China Shenzhen province, near Shenzhen air port east.

FAQ Are you manufacture or trad company? We are factory, located in China Shenzhen province, near Shenzhen air port east.Machine: 5 CNC Machines. 1 3d printer, 1 CNC lather machine etc. How about the QC? After the part has been machined it is checked against the drawing specifications

Before and after the finishing department has painted and polished the part it is inspected

The manager will personally check the products before they are packaged and sent for shipping What test tool do you have ? Hardness Tester (Shore A), Hardness Tester (Shore D), Humidity Gage, Color Standards,

Texture Standards , Color Scanner, Height Gage, Angle Gage, Hole Gage, Caliper (300MM),

Caliper (600MM), Caliper (1000MM), Color Assesment Cabinet. What Certificate do you have ?

ISO9001:2008

What would be provided to you when we need to make prototype?

The avaliable files for 3D Printing is : 3D drawings of .STL format and CMF ( Color, Material, Finish) Make Modles,Your Way!

Related Keywords

Related Keywords

You May Also Like

You May Also Like