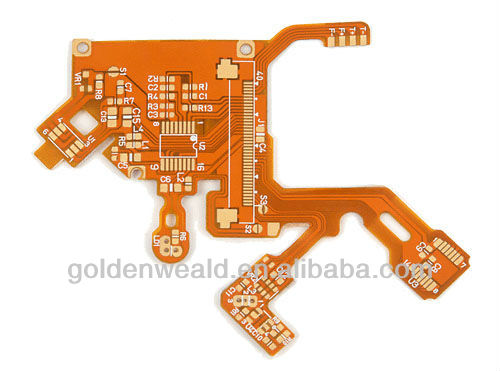

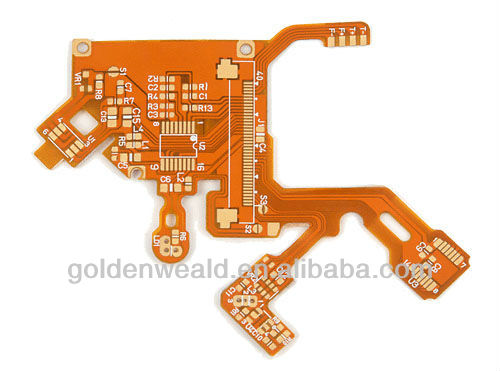

pcba samples manufacturers PCB Assembly flexible pcb

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

pcba samples manufacturers PCB Assembly flexible pcb Shen Zhen Golden Weald electronic Co.,ltd , 19 year experience professional Electronics PCBA Manufacturer ,PCBA Assembly ,flexible pcb,PCB Assembly manufacturer ! Product Description

Company Information

Company Information  flexible pcb Flex & Rigid-Flex circuits can be shaped to fit where no other design can. They are a hybrid of ordinary printed circuit boards and round wire, exhibiting benefits of each. In essence, flexible circuits give you unlimited freedom of packaging geometry while retaining the precision density and repeatability of printed circuits. As a high reliability replacement for wire and wire harness assemblies, flex circuits provide a significant cost savings with no reduction in performance. There are a variety of terminations for flex circuits and we can provide all of these as standard manufacturing process. Adding connectors and other minor component assembly is a common practice when producing flex and rigid flex circuits. Golden Weald has over 10 years of experience in building Printed Circuit Boards. Let our expertise in engineering and manufacturing assist you in meeting your Flexible Circuit Board needs. Flex Circuit Capabilities Below are our flex and rigid flex circuit capabilities, along with available materials substrates and adhesives. We also offer an extensive range of solder mask and coverlay products as well as various surface and finishes treatments. Our Flex Circuit Capabilities Include Single or Double Sided Circuitry Multi-layers, 2 to 6 FPC & Rigid-Flex Lines and Spaces: Single Sided .002", Double Sided .003" - .004" Installation of Connectors, Pins, Contacts, etc. Assembly including SMD Stiffener Supported Areas (using FR-4, Polyimide, Polyester, etc.) Unsupported Fingers Blind & Buried Vias Controlled Impedance Selective Adhesive Shielding, solid or patterned Forming & Creasing Circuits up to 18" x 24" Flex Circuit Materials Substrates Kapton: Polyimide 1/2 – 5 mils Mylar: Polyester 2 - 5 mils Epoxy Teflon Copper Half Hard Electro-deposited Adhesives Modified Acrylic Modified Epoxy Pressure Sensitive (PSA) Solder Mask / Coverlay Kapton Coverlay 1/2 mil to 5 mils Polyester Coverlay 1 mil to 3 mils Photoimageable Coverlay Soldermask Surface Treatment & Finishes Hard or Soft Gold Hot Air Level (H.A.L.) Carbon Printing Screen Print Solder Mask Silver Flex Circuit Benefits Package Size Reduction Flexible circuit thinness and light weight will enable a substantial packaging size reduction. Flexible circuit’s ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible. Cost Reduction Thin and flexible polyimide film requires a much smaller area, reducing the packaging size and overall material costs. Flex circuits used as interconnects reduce the number of connections to be soldered. Replacement for Wires & Wire Harness Assemblies Flexible circuits used to replace wiring reduces the errors common in hand wired assemblies. High Temperature Applications Flex circuits dissipate heat at a better rate than other dielectric materials. Expansion and contraction are minimized when using polyimide material. Weight Reduction Substantial weight reduction is a benefit over wires and wire harnesses. High Density Applications Flexible circuits allow for narrow lines giving way to high density device population. Denser device populations and lighter conductors can be designed into a product, freeing space for additional product features. Reliability & Durability The exceptional thermal stability of polyimide allows the circuit to withstand applications with extreme heat, as the materials excellent thermal stability provides a better base for surface mounting than traditional boards. Because the compliant base film places less stress on soldered joints, thermal mismatch is less likely to occur. Handle all customer's needs for PCB assembly, component purchasing and other product assemblies Printed Circuit Board Assembly Service OEM service for PCB, SMT, DIP assembly; Complete product assembly including structural parts, microchip programming and functional testing; ISO 9001, certified processes; Experienced Technical Staff Small orders can be accepted. Our Services Please keep reading the following about our services: - PCB Layout Design and Assembly - Mechanic Sample & Prototype Prepare - PCB Assembly - electronic Product OEM/ODM - Smart home - ID Design - Mechanic Design - Packing Design - Final Product Assembly ...... We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminium PCB with more than 13 years. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing. We sincerely hope to establish longtime and friendly business relationship with you. PCB assembly with reliably quantity, 100% testing Auto security & safety products, RoHS complaint Customed Service, Competitive price flexible pcb Packaging & Shipping

flexible pcb Flex & Rigid-Flex circuits can be shaped to fit where no other design can. They are a hybrid of ordinary printed circuit boards and round wire, exhibiting benefits of each. In essence, flexible circuits give you unlimited freedom of packaging geometry while retaining the precision density and repeatability of printed circuits. As a high reliability replacement for wire and wire harness assemblies, flex circuits provide a significant cost savings with no reduction in performance. There are a variety of terminations for flex circuits and we can provide all of these as standard manufacturing process. Adding connectors and other minor component assembly is a common practice when producing flex and rigid flex circuits. Golden Weald has over 10 years of experience in building Printed Circuit Boards. Let our expertise in engineering and manufacturing assist you in meeting your Flexible Circuit Board needs. Flex Circuit Capabilities Below are our flex and rigid flex circuit capabilities, along with available materials substrates and adhesives. We also offer an extensive range of solder mask and coverlay products as well as various surface and finishes treatments. Our Flex Circuit Capabilities Include Single or Double Sided Circuitry Multi-layers, 2 to 6 FPC & Rigid-Flex Lines and Spaces: Single Sided .002", Double Sided .003" - .004" Installation of Connectors, Pins, Contacts, etc. Assembly including SMD Stiffener Supported Areas (using FR-4, Polyimide, Polyester, etc.) Unsupported Fingers Blind & Buried Vias Controlled Impedance Selective Adhesive Shielding, solid or patterned Forming & Creasing Circuits up to 18" x 24" Flex Circuit Materials Substrates Kapton: Polyimide 1/2 – 5 mils Mylar: Polyester 2 - 5 mils Epoxy Teflon Copper Half Hard Electro-deposited Adhesives Modified Acrylic Modified Epoxy Pressure Sensitive (PSA) Solder Mask / Coverlay Kapton Coverlay 1/2 mil to 5 mils Polyester Coverlay 1 mil to 3 mils Photoimageable Coverlay Soldermask Surface Treatment & Finishes Hard or Soft Gold Hot Air Level (H.A.L.) Carbon Printing Screen Print Solder Mask Silver Flex Circuit Benefits Package Size Reduction Flexible circuit thinness and light weight will enable a substantial packaging size reduction. Flexible circuit’s ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible. Cost Reduction Thin and flexible polyimide film requires a much smaller area, reducing the packaging size and overall material costs. Flex circuits used as interconnects reduce the number of connections to be soldered. Replacement for Wires & Wire Harness Assemblies Flexible circuits used to replace wiring reduces the errors common in hand wired assemblies. High Temperature Applications Flex circuits dissipate heat at a better rate than other dielectric materials. Expansion and contraction are minimized when using polyimide material. Weight Reduction Substantial weight reduction is a benefit over wires and wire harnesses. High Density Applications Flexible circuits allow for narrow lines giving way to high density device population. Denser device populations and lighter conductors can be designed into a product, freeing space for additional product features. Reliability & Durability The exceptional thermal stability of polyimide allows the circuit to withstand applications with extreme heat, as the materials excellent thermal stability provides a better base for surface mounting than traditional boards. Because the compliant base film places less stress on soldered joints, thermal mismatch is less likely to occur. Handle all customer's needs for PCB assembly, component purchasing and other product assemblies Printed Circuit Board Assembly Service OEM service for PCB, SMT, DIP assembly; Complete product assembly including structural parts, microchip programming and functional testing; ISO 9001, certified processes; Experienced Technical Staff Small orders can be accepted. Our Services Please keep reading the following about our services: - PCB Layout Design and Assembly - Mechanic Sample & Prototype Prepare - PCB Assembly - electronic Product OEM/ODM - Smart home - ID Design - Mechanic Design - Packing Design - Final Product Assembly ...... We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminium PCB with more than 13 years. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing. We sincerely hope to establish longtime and friendly business relationship with you. PCB assembly with reliably quantity, 100% testing Auto security & safety products, RoHS complaint Customed Service, Competitive price flexible pcb Packaging & Shipping  flexible pcb PCBA Assembly Manufacturing package ESD bags; Honey Box; Outer carton (K=K 46x46x36CM) Customize is availble, Print logo and company information Shipping:

flexible pcb PCBA Assembly Manufacturing package ESD bags; Honey Box; Outer carton (K=K 46x46x36CM) Customize is availble, Print logo and company information Shipping:  flexible pcbpcba samples manufacturers PCB Assembly flexible pcbEurope Customer Visit Golden Weald Factory: UK Customer and Germany customers visit our factory and we have good business relationship with them for many years, they are also our good friends.

flexible pcbpcba samples manufacturers PCB Assembly flexible pcbEurope Customer Visit Golden Weald Factory: UK Customer and Germany customers visit our factory and we have good business relationship with them for many years, they are also our good friends.  Welcome to Golden Weald and have long term with you!

Welcome to Golden Weald and have long term with you!

Company Information

Company Information  flexible pcb Flex & Rigid-Flex circuits can be shaped to fit where no other design can. They are a hybrid of ordinary printed circuit boards and round wire, exhibiting benefits of each. In essence, flexible circuits give you unlimited freedom of packaging geometry while retaining the precision density and repeatability of printed circuits. As a high reliability replacement for wire and wire harness assemblies, flex circuits provide a significant cost savings with no reduction in performance. There are a variety of terminations for flex circuits and we can provide all of these as standard manufacturing process. Adding connectors and other minor component assembly is a common practice when producing flex and rigid flex circuits. Golden Weald has over 10 years of experience in building Printed Circuit Boards. Let our expertise in engineering and manufacturing assist you in meeting your Flexible Circuit Board needs. Flex Circuit Capabilities Below are our flex and rigid flex circuit capabilities, along with available materials substrates and adhesives. We also offer an extensive range of solder mask and coverlay products as well as various surface and finishes treatments. Our Flex Circuit Capabilities Include Single or Double Sided Circuitry Multi-layers, 2 to 6 FPC & Rigid-Flex Lines and Spaces: Single Sided .002", Double Sided .003" - .004" Installation of Connectors, Pins, Contacts, etc. Assembly including SMD Stiffener Supported Areas (using FR-4, Polyimide, Polyester, etc.) Unsupported Fingers Blind & Buried Vias Controlled Impedance Selective Adhesive Shielding, solid or patterned Forming & Creasing Circuits up to 18" x 24" Flex Circuit Materials Substrates Kapton: Polyimide 1/2 – 5 mils Mylar: Polyester 2 - 5 mils Epoxy Teflon Copper Half Hard Electro-deposited Adhesives Modified Acrylic Modified Epoxy Pressure Sensitive (PSA) Solder Mask / Coverlay Kapton Coverlay 1/2 mil to 5 mils Polyester Coverlay 1 mil to 3 mils Photoimageable Coverlay Soldermask Surface Treatment & Finishes Hard or Soft Gold Hot Air Level (H.A.L.) Carbon Printing Screen Print Solder Mask Silver Flex Circuit Benefits Package Size Reduction Flexible circuit thinness and light weight will enable a substantial packaging size reduction. Flexible circuit’s ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible. Cost Reduction Thin and flexible polyimide film requires a much smaller area, reducing the packaging size and overall material costs. Flex circuits used as interconnects reduce the number of connections to be soldered. Replacement for Wires & Wire Harness Assemblies Flexible circuits used to replace wiring reduces the errors common in hand wired assemblies. High Temperature Applications Flex circuits dissipate heat at a better rate than other dielectric materials. Expansion and contraction are minimized when using polyimide material. Weight Reduction Substantial weight reduction is a benefit over wires and wire harnesses. High Density Applications Flexible circuits allow for narrow lines giving way to high density device population. Denser device populations and lighter conductors can be designed into a product, freeing space for additional product features. Reliability & Durability The exceptional thermal stability of polyimide allows the circuit to withstand applications with extreme heat, as the materials excellent thermal stability provides a better base for surface mounting than traditional boards. Because the compliant base film places less stress on soldered joints, thermal mismatch is less likely to occur. Handle all customer's needs for PCB assembly, component purchasing and other product assemblies Printed Circuit Board Assembly Service OEM service for PCB, SMT, DIP assembly; Complete product assembly including structural parts, microchip programming and functional testing; ISO 9001, certified processes; Experienced Technical Staff Small orders can be accepted. Our Services Please keep reading the following about our services: - PCB Layout Design and Assembly - Mechanic Sample & Prototype Prepare - PCB Assembly - electronic Product OEM/ODM - Smart home - ID Design - Mechanic Design - Packing Design - Final Product Assembly ...... We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminium PCB with more than 13 years. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing. We sincerely hope to establish longtime and friendly business relationship with you. PCB assembly with reliably quantity, 100% testing Auto security & safety products, RoHS complaint Customed Service, Competitive price flexible pcb Packaging & Shipping

flexible pcb Flex & Rigid-Flex circuits can be shaped to fit where no other design can. They are a hybrid of ordinary printed circuit boards and round wire, exhibiting benefits of each. In essence, flexible circuits give you unlimited freedom of packaging geometry while retaining the precision density and repeatability of printed circuits. As a high reliability replacement for wire and wire harness assemblies, flex circuits provide a significant cost savings with no reduction in performance. There are a variety of terminations for flex circuits and we can provide all of these as standard manufacturing process. Adding connectors and other minor component assembly is a common practice when producing flex and rigid flex circuits. Golden Weald has over 10 years of experience in building Printed Circuit Boards. Let our expertise in engineering and manufacturing assist you in meeting your Flexible Circuit Board needs. Flex Circuit Capabilities Below are our flex and rigid flex circuit capabilities, along with available materials substrates and adhesives. We also offer an extensive range of solder mask and coverlay products as well as various surface and finishes treatments. Our Flex Circuit Capabilities Include Single or Double Sided Circuitry Multi-layers, 2 to 6 FPC & Rigid-Flex Lines and Spaces: Single Sided .002", Double Sided .003" - .004" Installation of Connectors, Pins, Contacts, etc. Assembly including SMD Stiffener Supported Areas (using FR-4, Polyimide, Polyester, etc.) Unsupported Fingers Blind & Buried Vias Controlled Impedance Selective Adhesive Shielding, solid or patterned Forming & Creasing Circuits up to 18" x 24" Flex Circuit Materials Substrates Kapton: Polyimide 1/2 – 5 mils Mylar: Polyester 2 - 5 mils Epoxy Teflon Copper Half Hard Electro-deposited Adhesives Modified Acrylic Modified Epoxy Pressure Sensitive (PSA) Solder Mask / Coverlay Kapton Coverlay 1/2 mil to 5 mils Polyester Coverlay 1 mil to 3 mils Photoimageable Coverlay Soldermask Surface Treatment & Finishes Hard or Soft Gold Hot Air Level (H.A.L.) Carbon Printing Screen Print Solder Mask Silver Flex Circuit Benefits Package Size Reduction Flexible circuit thinness and light weight will enable a substantial packaging size reduction. Flexible circuit’s ability to be folded or creased and positioned into the smallest areas makes miniaturization of many devices possible. Cost Reduction Thin and flexible polyimide film requires a much smaller area, reducing the packaging size and overall material costs. Flex circuits used as interconnects reduce the number of connections to be soldered. Replacement for Wires & Wire Harness Assemblies Flexible circuits used to replace wiring reduces the errors common in hand wired assemblies. High Temperature Applications Flex circuits dissipate heat at a better rate than other dielectric materials. Expansion and contraction are minimized when using polyimide material. Weight Reduction Substantial weight reduction is a benefit over wires and wire harnesses. High Density Applications Flexible circuits allow for narrow lines giving way to high density device population. Denser device populations and lighter conductors can be designed into a product, freeing space for additional product features. Reliability & Durability The exceptional thermal stability of polyimide allows the circuit to withstand applications with extreme heat, as the materials excellent thermal stability provides a better base for surface mounting than traditional boards. Because the compliant base film places less stress on soldered joints, thermal mismatch is less likely to occur. Handle all customer's needs for PCB assembly, component purchasing and other product assemblies Printed Circuit Board Assembly Service OEM service for PCB, SMT, DIP assembly; Complete product assembly including structural parts, microchip programming and functional testing; ISO 9001, certified processes; Experienced Technical Staff Small orders can be accepted. Our Services Please keep reading the following about our services: - PCB Layout Design and Assembly - Mechanic Sample & Prototype Prepare - PCB Assembly - electronic Product OEM/ODM - Smart home - ID Design - Mechanic Design - Packing Design - Final Product Assembly ...... We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminium PCB with more than 13 years. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing. We sincerely hope to establish longtime and friendly business relationship with you. PCB assembly with reliably quantity, 100% testing Auto security & safety products, RoHS complaint Customed Service, Competitive price flexible pcb Packaging & Shipping  flexible pcb PCBA Assembly Manufacturing package ESD bags; Honey Box; Outer carton (K=K 46x46x36CM) Customize is availble, Print logo and company information Shipping:

flexible pcb PCBA Assembly Manufacturing package ESD bags; Honey Box; Outer carton (K=K 46x46x36CM) Customize is availble, Print logo and company information Shipping:  flexible pcbpcba samples manufacturers PCB Assembly flexible pcbEurope Customer Visit Golden Weald Factory: UK Customer and Germany customers visit our factory and we have good business relationship with them for many years, they are also our good friends.

flexible pcbpcba samples manufacturers PCB Assembly flexible pcbEurope Customer Visit Golden Weald Factory: UK Customer and Germany customers visit our factory and we have good business relationship with them for many years, they are also our good friends.  Welcome to Golden Weald and have long term with you!

Welcome to Golden Weald and have long term with you! Related Keywords

Related Keywords

You May Also Like

You May Also Like