High precision CNC engraving and milling machine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

It is a kind of engraving machine CNC machine tool. Metal laser engraving machine can be of metal or non-metal plate and pipe non-contact cutting and boring, especially suitable for stainless steel, iron, silicon, ceramics, titanium alloy, epoxy, A3 steel, diamond materials of laser cutting processing. The equipment is stable and reliable operation, good processing quality, high efficiency, easy operation and easy maintenance. That is the use of small engraving machine CNC milling machine tool, high power and high speed spindle motor. Foreign countries, and there is no concept of engraving machine, mold processing they are dominated by milling machining center (computer gongs), but machining center has its shortcomings, especially in small tool to process small mold appeared to be inadequate, and the cost is very high. At home, only the concept of CNC engraving machine, engraving machine advantage in the carving, if the hardness of the processing materials will also appear to be inadequate. Have carved machine can be said to fill the gap between the two. The machine can also be milling, carving, is a kind of high efficient and high precision NC machine tool. Engraving machine: can the precise carving, or milling, engraving machine based on increased spindle servo motor power, bed capacity, while maintaining the spindle speed, more important is precision is very high. The carving machine to multi beam Shiju. For the completion of small carved machine milling, machining small mold, suitable for processing copper and graphite. NC carving machine for small milling, processing equipment or soft metal. Machine tool is divided into two parts, moving parts and moving parts: table, skateboarding, cross children as part of the mobile and the bed, column for non moving part. Non moving part steel requirements of mobile part of steel to a flexible under the premise, as far as possible some light while maintaining certain steel. Advantages: can be relatively small processing, high processing precision. The soft metal can be processed at high speed; the disadvantage is that it is not possible to carry out heavy cutting because of the poor quality of the steel. CNC system requirements of high speed engraving machine, spindle speed is about 3000~30000RPM. Milling machines are usually thought Cimatron tool path to be a little better, the new version of the software fully elegant to the uniformity of the cutting tool in the moment, especially the knife into the work out of the moment of speed and smooth, and the inflection point follow difference algorithm followingError, make the results and graphic design more stick into. Part of the CAD just uses a lot of intuitive 3D solid modeling such as SolidWorks by IGS into CAM software for processing.

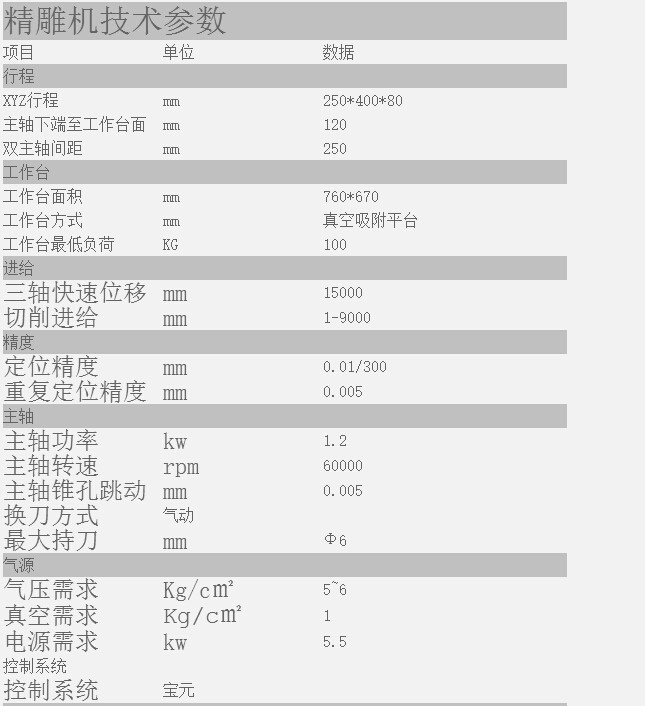

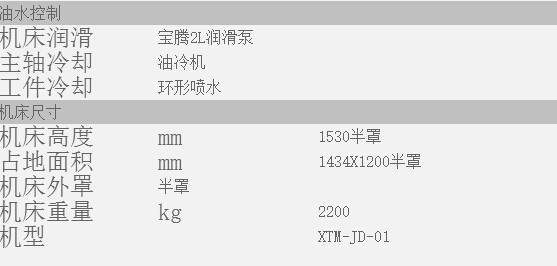

It is a kind of engraving machine CNC machine tool. Metal laser engraving machine can be of metal or non-metal plate and pipe non-contact cutting and boring, especially suitable for stainless steel, iron, silicon, ceramics, titanium alloy, epoxy, A3 steel, diamond materials of laser cutting processing. The equipment is stable and reliable operation, good processing quality, high efficiency, easy operation and easy maintenance. That is the use of small engraving machine CNC milling machine tool, high power and high speed spindle motor. Foreign countries, and there is no concept of engraving machine, mold processing they are dominated by milling machining center (computer gongs), but machining center has its shortcomings, especially in small tool to process small mold appeared to be inadequate, and the cost is very high. At home, only the concept of CNC engraving machine, engraving machine advantage in the carving, if the hardness of the processing materials will also appear to be inadequate. Have carved machine can be said to fill the gap between the two. The machine can also be milling, carving, is a kind of high efficient and high precision NC machine tool. Engraving machine: can the precise carving, or milling, engraving machine based on increased spindle servo motor power, bed capacity, while maintaining the spindle speed, more important is precision is very high. The carving machine to multi beam Shiju. For the completion of small carved machine milling, machining small mold, suitable for processing copper and graphite. NC carving machine for small milling, processing equipment or soft metal. Machine tool is divided into two parts, moving parts and moving parts: table, skateboarding, cross children as part of the mobile and the bed, column for non moving part. Non moving part steel requirements of mobile part of steel to a flexible under the premise, as far as possible some light while maintaining certain steel. Advantages: can be relatively small processing, high processing precision. The soft metal can be processed at high speed; the disadvantage is that it is not possible to carry out heavy cutting because of the poor quality of the steel. CNC system requirements of high speed engraving machine, spindle speed is about 3000~30000RPM. Milling machines are usually thought Cimatron tool path to be a little better, the new version of the software fully elegant to the uniformity of the cutting tool in the moment, especially the knife into the work out of the moment of speed and smooth, and the inflection point follow difference algorithm followingError, make the results and graphic design more stick into. Part of the CAD just uses a lot of intuitive 3D solid modeling such as SolidWorks by IGS into CAM software for processing.Parameter index data:

1, spindle speed (r/min): 240000 of the most common carved carving machine.

2, spindle power: General in less than ten kilowatts.

3, cutting quantity: fine times.

4, speed: up to 120m/min.

5, accuracy: high precision.

6, from the processing size: the largest carved machine table area in 700*620 (750).

7, from the application object: engraving machine to complete the milling capacity is small, small die finishing, suitable for processing of copper and graphite. The machine can make products, also can do the mold.

Related Keywords

Related Keywords

You May Also Like

You May Also Like