110V 220V High Voltage Led Flexible Strip

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Specification

Product Description  Product features

Product features

1.Led flexible strip with using high quality Epistar or Sanan chips.

2. Optional led types: SMD5050/SMD2835/SMD3528/ SMD5730 /SMD3014. 3. Color available: White/Warm White/Yellow/Pink/Red/ Green/Blue/RGB/Five colors jumpy. 4. Optional voltage: AC220V/AC110V Led Flexible Strip Product Details 110V 220V High Voltage Led Flexible Strip

1. IP 67 PVC jacket, can be used in outdoor. 2. Superior and heat-resistant FPCB board. 3. Led flexible strip can be cut, easy to install. 4. Without power adapter, can be directly connected to AC power supply.

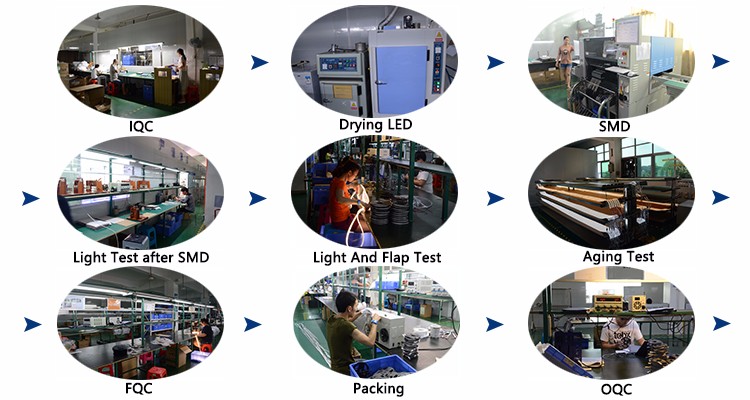

Strict Quality Control We have a strict quality control system from raw material to finished led strips.Each step must pass strict inspection, strive to produce superior products:

Strict Quality Control We have a strict quality control system from raw material to finished led strips.Each step must pass strict inspection, strive to produce superior products:

1.Incoming Raw Material Inspection

Comparing incoming raw material and sealed sample in terms of class, quality grade, technical data, ensuring the consistency with purchasing requirements, thus guarantee the ensuing manufactured product fulfilling customers’ requirements.

2.Led Drying

Leds of Led Flexible Strip will absorb humidity when exposed to air, which requires 24H drying before SMD.

3.Light-on Test after SMD

After pasting of leds onto the PCB board, each strip panels will be powered to see if any insufficient soldering, slanted leds, and dead leds, if yes, they have to be repaired until qualified; if no, then flowing to the next stream.

4.Light-on and beating test

Strips after SMD (0.5M) should be soldered to 5M roll, after which they have to be lighted again to check if any dead leds, and together with beating test to see if leds fixed tight on pcb board

5.Aging Test

Finished products must undergo at least 8 hours’ aging test 100%

6.Light-on test of finished product

Finished product, before packing, must be lighted again after aging to check if any dead leds.

7.Pre-shipment Inspection

Proofing finished product with customers’ requirements again before shipment, to ensure the consistency of products with customers' needs.

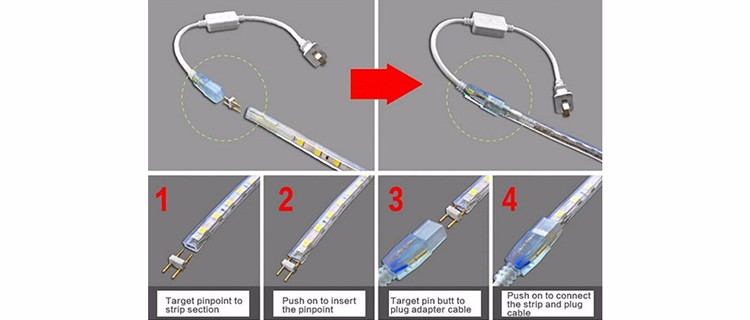

Led Flexible Strip Linking operation: 1. Target pinpoint to strip section. 2. Push on to insert the pinpoint. 3. Target pin butt to plug adapter cable. 4. Push on to connect the flexible strip and plug cable. Applications

Led Flexible Strip Linking operation: 1. Target pinpoint to strip section. 2. Push on to insert the pinpoint. 3. Target pin butt to plug adapter cable. 4. Push on to connect the flexible strip and plug cable. Applications

Led Flexible Strip widely used in cove lighting, architectural lights for canopy, corridor, Archway, backlight or edge lighting for signage, DIY lights for home use. Certifications

Led Flexible Strip widely used in cove lighting, architectural lights for canopy, corridor, Archway, backlight or edge lighting for signage, DIY lights for home use. Certifications

Led flexible strip have passed CE, RoHs certifying. Company Information

Led flexible strip have passed CE, RoHs certifying. Company Information

Product features

Product features1.Led flexible strip with using high quality Epistar or Sanan chips.

2. Optional led types: SMD5050/SMD2835/SMD3528/ SMD5730 /SMD3014. 3. Color available: White/Warm White/Yellow/Pink/Red/ Green/Blue/RGB/Five colors jumpy. 4. Optional voltage: AC220V/AC110V Led Flexible Strip Product Details 110V 220V High Voltage Led Flexible Strip

1. IP 67 PVC jacket, can be used in outdoor. 2. Superior and heat-resistant FPCB board. 3. Led flexible strip can be cut, easy to install. 4. Without power adapter, can be directly connected to AC power supply.

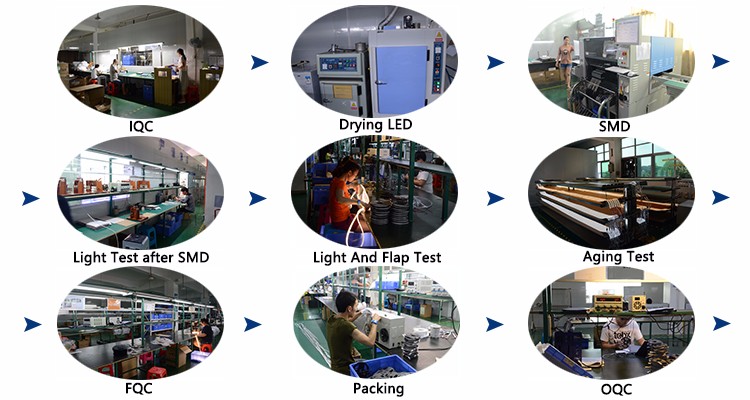

Strict Quality Control We have a strict quality control system from raw material to finished led strips.Each step must pass strict inspection, strive to produce superior products:

Strict Quality Control We have a strict quality control system from raw material to finished led strips.Each step must pass strict inspection, strive to produce superior products:1.Incoming Raw Material Inspection

Comparing incoming raw material and sealed sample in terms of class, quality grade, technical data, ensuring the consistency with purchasing requirements, thus guarantee the ensuing manufactured product fulfilling customers’ requirements.

2.Led Drying

Leds of Led Flexible Strip will absorb humidity when exposed to air, which requires 24H drying before SMD.

3.Light-on Test after SMD

After pasting of leds onto the PCB board, each strip panels will be powered to see if any insufficient soldering, slanted leds, and dead leds, if yes, they have to be repaired until qualified; if no, then flowing to the next stream.

4.Light-on and beating test

Strips after SMD (0.5M) should be soldered to 5M roll, after which they have to be lighted again to check if any dead leds, and together with beating test to see if leds fixed tight on pcb board

5.Aging Test

Finished products must undergo at least 8 hours’ aging test 100%

6.Light-on test of finished product

Finished product, before packing, must be lighted again after aging to check if any dead leds.

7.Pre-shipment Inspection

Proofing finished product with customers’ requirements again before shipment, to ensure the consistency of products with customers' needs.

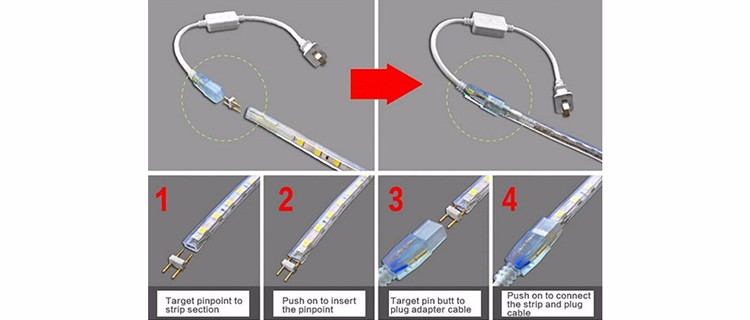

Led Flexible Strip Linking operation: 1. Target pinpoint to strip section. 2. Push on to insert the pinpoint. 3. Target pin butt to plug adapter cable. 4. Push on to connect the flexible strip and plug cable. Applications

Led Flexible Strip Linking operation: 1. Target pinpoint to strip section. 2. Push on to insert the pinpoint. 3. Target pin butt to plug adapter cable. 4. Push on to connect the flexible strip and plug cable. Applications

Led Flexible Strip widely used in cove lighting, architectural lights for canopy, corridor, Archway, backlight or edge lighting for signage, DIY lights for home use. Certifications

Led Flexible Strip widely used in cove lighting, architectural lights for canopy, corridor, Archway, backlight or edge lighting for signage, DIY lights for home use. Certifications

Led flexible strip have passed CE, RoHs certifying. Company Information

Led flexible strip have passed CE, RoHs certifying. Company Information

Related Keywords

Related Keywords

You May Also Like

You May Also Like