Glow in Dark Pigment Powder for Glow Mobile Phone Case

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

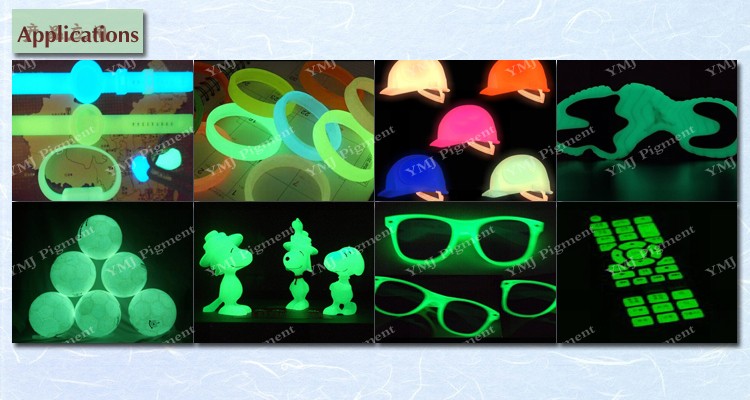

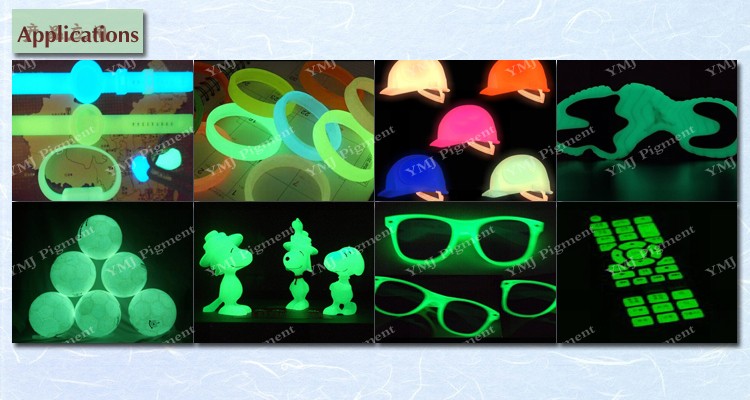

Glow in Dark Pigment Powder for Glow Mobile Phone Case Product Description Features Photoluminescent Pigment is strontium aluminate based glow material activated by rare earth raw material. Glow Powder is also called as Glow Pigment/Glow in the Dark Powder/Photoluminescent Pigment/Luminous Powder/Noctilucent Powder/Night glow pigment etc 1. More than 10 colors for your choice. Yellow-green, Sky-blue, Blue-green has the best glowing brightness. 2. Harmless to human body, eco-friendly, non-toxic, non-radioactivity, non-explosibility. 3. Widely applied in variety of transparent or translucent mediums to make products glow in the dark. 4. Can absorb any visible light such as ultraviolet,lamplight,sunlight and other visible lights ,only 15-30 minutes and then can glow for more than 8 hours. 5. More than 20 years operation life. 6. Stable physical and chemical property, can be easily mixture with all kinds of chemicals. Characteristics Particle size: 5-90um Appearance: Light green/light white, multicolor Glow Color: Yellow-green, Blue-green, Sky-blue, multicolor Application range: Spray paint, Brush paint, Screen printing ink, Thermoplastic, Rubber, Fabric dyeing etc. Proportion: Injection molding: 2-10%; Varnishing: 20-50% Material: Strontium aluminate based glow material activated by rare earth Excitation condition: Sunlight, general lighting, ambient stray light  Applications: 1. Luminous paint: Propylene kind, alcoholic acid kind, epoxy resin type of varnish is recommended to use. 2.Coating: Coating has its own coating powder-general phosphor powder, made by special coating treatment. It can prevent the hydrolysis and improve the storage time of the luminous coating. 3.Plastic: Luminous powder can be added in the molding of plastic or light-emitting plastic film panels, light-emitting plastic toys, plastic light-emitting Signs, etc. 4.Also used in ceramics. 5.Mixed with synthetic resin crafts molding. 6.Cosmetics use: glow nail polish. Glow Powder for Plastics Normally 2~10% dosage rate by weight is OK for plastic industry(i.e. 1kg pigment to mix with 25kgs plastic resins), more PL pigment shall be added if the plastic resin is not good in transparency. The lower MI the resin, the higher pigment dosage rate is required. To add some reflective glass beads will do help to increase glowing performance.

Applications: 1. Luminous paint: Propylene kind, alcoholic acid kind, epoxy resin type of varnish is recommended to use. 2.Coating: Coating has its own coating powder-general phosphor powder, made by special coating treatment. It can prevent the hydrolysis and improve the storage time of the luminous coating. 3.Plastic: Luminous powder can be added in the molding of plastic or light-emitting plastic film panels, light-emitting plastic toys, plastic light-emitting Signs, etc. 4.Also used in ceramics. 5.Mixed with synthetic resin crafts molding. 6.Cosmetics use: glow nail polish. Glow Powder for Plastics Normally 2~10% dosage rate by weight is OK for plastic industry(i.e. 1kg pigment to mix with 25kgs plastic resins), more PL pigment shall be added if the plastic resin is not good in transparency. The lower MI the resin, the higher pigment dosage rate is required. To add some reflective glass beads will do help to increase glowing performance.  Packaging & Shipping

Packaging & Shipping  Photoluminescent Pigment for glow mobile phone case:

Photoluminescent Pigment for glow mobile phone case:  Company Information

Company Information

For more information, you are welcome to contact us by sc anning below QR Code.

For more information, you are welcome to contact us by sc anning below QR Code.

Applications: 1. Luminous paint: Propylene kind, alcoholic acid kind, epoxy resin type of varnish is recommended to use. 2.Coating: Coating has its own coating powder-general phosphor powder, made by special coating treatment. It can prevent the hydrolysis and improve the storage time of the luminous coating. 3.Plastic: Luminous powder can be added in the molding of plastic or light-emitting plastic film panels, light-emitting plastic toys, plastic light-emitting Signs, etc. 4.Also used in ceramics. 5.Mixed with synthetic resin crafts molding. 6.Cosmetics use: glow nail polish. Glow Powder for Plastics Normally 2~10% dosage rate by weight is OK for plastic industry(i.e. 1kg pigment to mix with 25kgs plastic resins), more PL pigment shall be added if the plastic resin is not good in transparency. The lower MI the resin, the higher pigment dosage rate is required. To add some reflective glass beads will do help to increase glowing performance.

Applications: 1. Luminous paint: Propylene kind, alcoholic acid kind, epoxy resin type of varnish is recommended to use. 2.Coating: Coating has its own coating powder-general phosphor powder, made by special coating treatment. It can prevent the hydrolysis and improve the storage time of the luminous coating. 3.Plastic: Luminous powder can be added in the molding of plastic or light-emitting plastic film panels, light-emitting plastic toys, plastic light-emitting Signs, etc. 4.Also used in ceramics. 5.Mixed with synthetic resin crafts molding. 6.Cosmetics use: glow nail polish. Glow Powder for Plastics Normally 2~10% dosage rate by weight is OK for plastic industry(i.e. 1kg pigment to mix with 25kgs plastic resins), more PL pigment shall be added if the plastic resin is not good in transparency. The lower MI the resin, the higher pigment dosage rate is required. To add some reflective glass beads will do help to increase glowing performance.  Packaging & Shipping

Packaging & Shipping  Photoluminescent Pigment for glow mobile phone case:

Photoluminescent Pigment for glow mobile phone case:  Company Information

Company Information

For more information, you are welcome to contact us by sc anning below QR Code.

For more information, you are welcome to contact us by sc anning below QR Code.

Related Keywords

Related Keywords